Reliable gauge calibration isn’t just about applying a reference pressure and writing down numbers. Accuracy class, pressure media, contamination control, elevation head, leak checks, mounting position, how you generate pressure, pre-cycling, gas thermodynamics, and even wrench torque all matter. Get these right and your results will actually reflect reality.

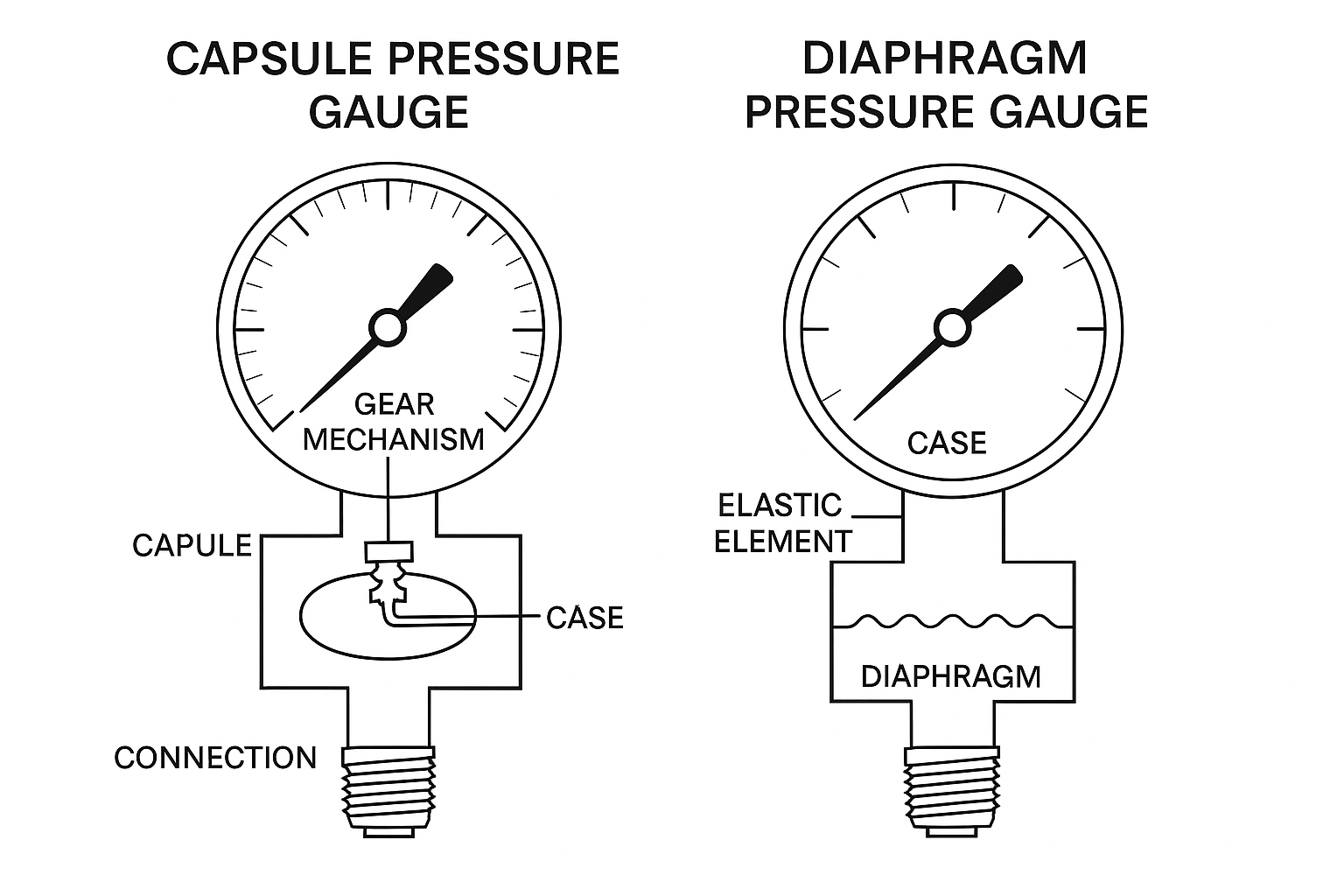

1) Know the Accuracy Class (and what “% of range” really means)

Gauge accuracy is defined by standards such as ASME B40.100 and EN 837. Classes typically span 0.1–5% (ASME) or 0.1–4% (EN). A “1% of range” gauge over 0–100 psi means ±1 psi allowable error anywhere on the scale. Select and interpret the class correctly before you design the calibration points and tolerances.

2) Choose the Right Pressure Medium

Air (or nitrogen) is common for low pressures; liquids (water or oil) are safer and more practical as pressure rises. Match the calibration medium to the process medium and the range you’re verifying to avoid medium-induced artifacts.

3) Control Contamination—Especially for Oxygen Service

Dirt and residual process fluid can damage controllers and skew readings. Use dirt/moisture traps for pneumatic paths; clean liquid-filled instruments before connecting. For oxygen service, any grease or oil in a high-pressure line can be hazardous—treat cleaning as a safety-critical step.

4) Correct for Elevation (Hydrostatic Head)

If the gauge and the calibrator are at different heights and you’re using a liquid medium, hydrostatic head introduces a pressure offset. Either level the hardware or correct mathematically for density and height difference.

Rule of thumb (for liquids): ΔP=ρgh

5) Prove the System is Tight (Leak Test)

Before you trust readings, pressurize, isolate, and let the system stabilize—monitor that pressure does not fall. If your controller auto-regulates pressure, disable regulation to perform a closed-system check. In gas systems, don’t misdiagnose normal adiabatic cool-down as a leak (see Factor 9).

6) Match Calibration/Installation Position

Mechanical gauges are position-sensitive. Calibrate in the same orientation they’ll be used in. A typical spec: a 5° position change should not shift indication by more than half the accuracy class.

7) Generate Pressure the Smart Way

Hand pumps, bottled-gas regulators, and deadweight testers are all valid. Deadweight testers give primary-standard accuracy but are costly, less portable, and sensitive to contamination—choose based on accuracy needs and field realities.

8) Exercise” the Gauge Before You Measure

Friction in mechanical movements can cause temporary hysteresis. Pre-cycle to full rated pressure, hold ~1 min, vent, wait ~1 min, and repeat 2–3 times to stabilize behavior before the actual points.

9) Respect Adiabatic Effects in Gases

In closed gas systems, fast pressurization heats the gas and raises pressure; as it cools, pressure falls. Allow adequate settling time before recording data or declaring leaks—rate of change matters.

10) Use Proper Torque and Tooling

Over-tightening torque-sensitive gauges can permanently shift readings or damage threads. Follow the manufacturer’s torque spec and use the right adapters and seals—no “cheater bars.”

Practical Checklist (copy/paste for the bench)

Confirm accuracy class and acceptance criteria.

Match medium (air/liquid) to process and range.

Inspect/clean; set traps; oxygen-service precautions.

Level or correct elevation (use ρgh\rho g hρgh).

Leak test in a closed system; account for gas cool-down.

Match orientation to service position.

Select a pressure source fit for purpose.

Exercise gauge (2–3 cycles) before data.

Allow stabilization in gas systems (adiabatic).

Apply correct torque with proper tooling

Closing Thought

Calibrating a pressure gauge is a system problem, not a single number. Treat the setup, medium, mechanics, and physics with equal respect; your certificates—and your process—will thank you.