Introduction

Temperature transmitters are among the most widely used instruments in industrial measurement and control. By converting temperature signals into standardized electrical outputs, they play a vital role in ensuring product quality, process safety, and energy efficiency.

Depending on the measurement method, temperature transmitters can be broadly classified into contact-type (e.g., RTDs, thermocouples) and non-contact type (e.g., infrared sensors, pyrometers). In practice, transmitters are often integrated with other instruments and control systems, forming the backbone of modern automation.

However, like all field devices, temperature transmitters may encounter failures during operation. To minimize downtime and avoid costly disruptions, maintenance teams must be familiar with effective troubleshooting and safe repair practices.

Common Troubleshooting Methods

When a temperature transmitter malfunctions, technicians typically rely on three main diagnostic approaches:

1. Replacement Method

Overview: This is the fastest and most straightforward troubleshooting method, provided spare parts are available.

Application: Replace the suspected faulty transmitter with a spare unit. If the system resumes normal operation, the removed device is confirmed defective.

Benefit: Saves time in critical processes where delays are unacceptable.

Limitation: Requires spare inventory, which may not always be feasible in remote sites.

2. Elimination Method

Overview: Systematically isolate the fault by excluding equipment confirmed to be functioning properly.

Application: Start from known healthy devices and connections, progressively narrowing down to the problematic transmitter.

Benefit: Logical, step-by-step approach that reduces unnecessary part replacements.

Limitation: More time-consuming compared to direct replacement.

3. Testing Method

Overview: Use diagnostic tools such as a multimeter to measure resistance, voltage, or current values.

Application: Check the sensor element (e.g., RTD resistance curve), transmitter output (4–20 mA loop signal), and power supply.

Benefit: Provides precise identification of the fault location.

Limitation: Requires skilled personnel familiar with electrical measurement techniques.

Safety Precautions During Maintenance

Repairing and inspecting temperature transmitters involve strict safety rules. Ignoring them may lead to accidents, equipment damage, or inaccurate measurements.

Never perform live maintenance:

Avoid working on collectors, junction boxes, or plugging/unplugging cables while the circuit is energized.Do not replace sensors under power:

Installing or removing RTDs, thermocouples, or other sensors while the system is live may cause short circuits or equipment failure.Check environmental conditions:

During adverse weather (strong wind, heavy rain), verify whether ground temperature fields have been affected. If anomalies are detected, restore the field conditions before proceeding.Daily enclosure inspection:

Ensure that junction boxes are properly sealed against moisture and dust.

Check for standing water inside the housing.

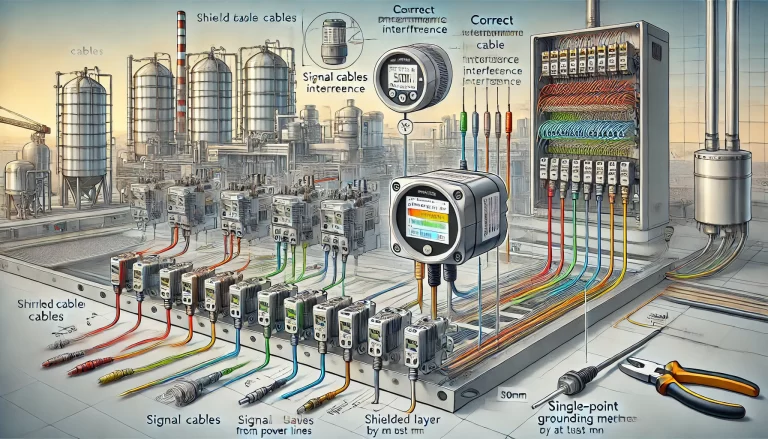

Inspect exposed cables for cracks, insulation damage, or loose connections.

Practical Tips for Field Engineers

Document everything: Keep detailed records of failures, corrective actions, and replaced parts. This supports predictive maintenance strategies.

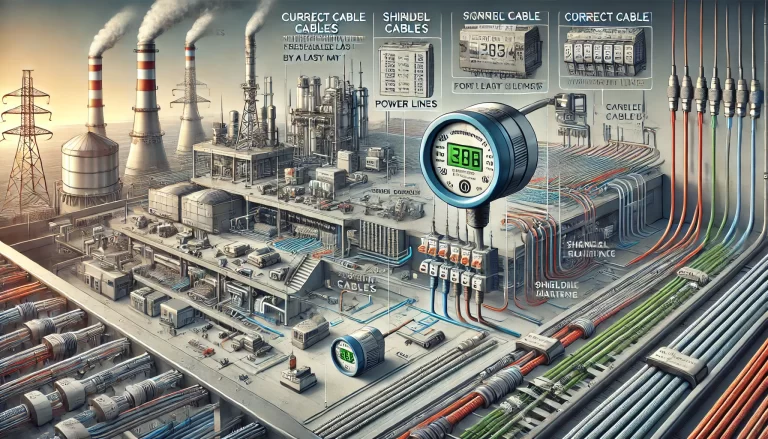

Use diagnostic software: Many modern transmitters support HART, Foundation Fieldbus, or PROFIBUS protocols, allowing remote diagnostics and parameter adjustment.

Train staff regularly: Operators should be trained not only in troubleshooting but also in preventive measures such as proper cable routing, shielding, and grounding.

Adopt preventive maintenance: Regular calibration, loop checks, and environmental inspections reduce the risk of sudden transmitter failure.

Conclusion

Temperature transmitters may appear simple, but their reliability is essential for safe and efficient industrial operations. By applying systematic troubleshooting methods—replacement, elimination, and testing—along with rigorous safety precautions, maintenance teams can minimize downtime and extend the service life of these instruments.

In the era of smart factories, combining traditional troubleshooting skills with digital diagnostic tools and preventive maintenance programs will ensure temperature transmitters continue to deliver accurate and reliable data for years to come.