The selection of the pressure tapping point is a critical factor that directly affects the accuracy and reliability of pressure measurement in industrial processes. Proper tapping location varies depending on the process medium (gas, liquid, or steam), flow characteristics, and installation conditions. This document outlines key technical principles to ensure correct tapping point selection and optimal pressure sensor performance.

1. Selection Based on Medium Type

1.1 Gas Pressure Measurement

The tapping point should be located on the upper half of the pipeline.

This prevents condensate from collecting in the impulse line and affecting measurement accuracy.

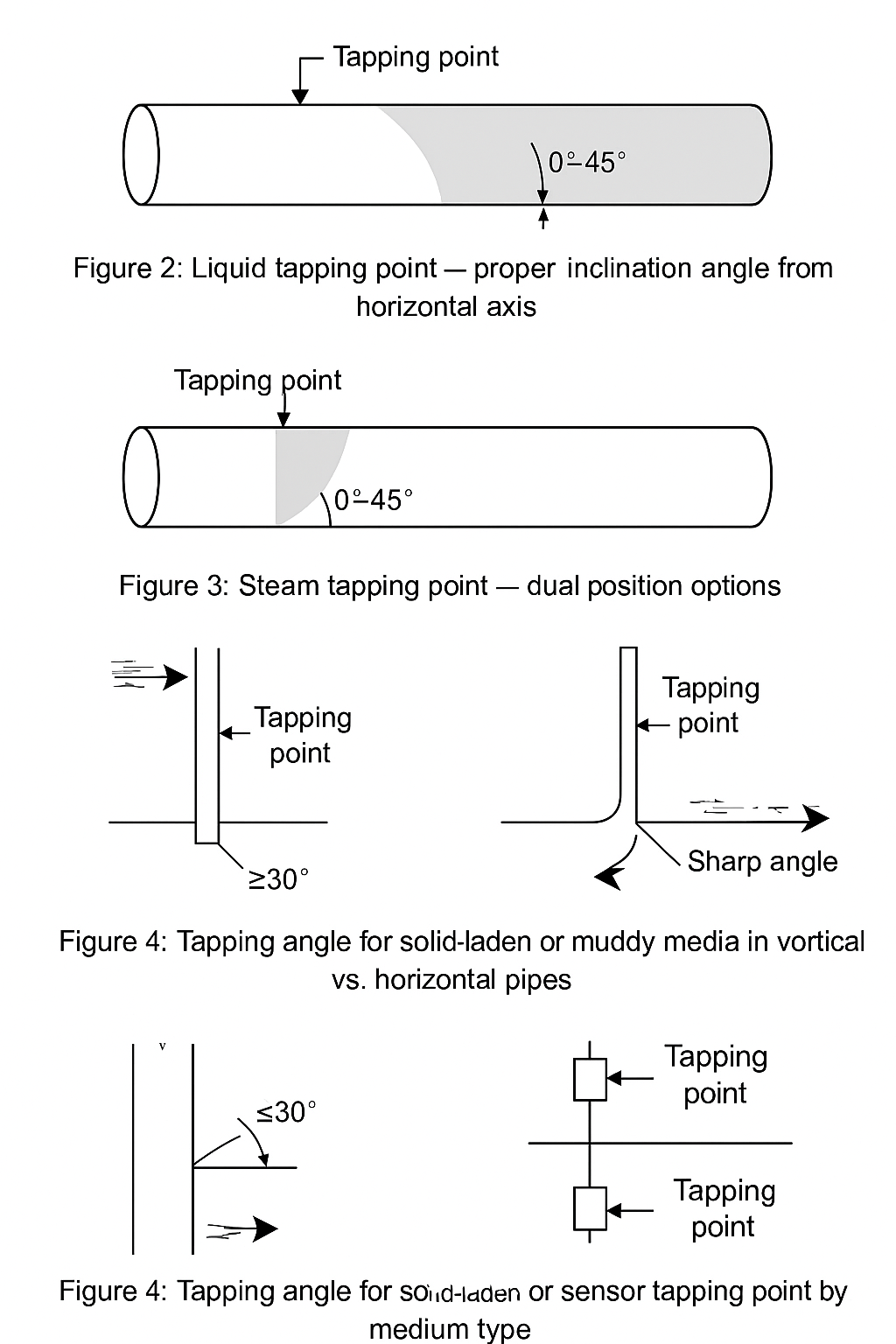

1.2 Liquid Pressure Measurement

The tapping point should be positioned on the lower half of the pipeline.

It should lie within a 0° to 45° downward angle relative to the horizontal centerline to avoid gas entrapment.

1.3 Steam Pressure Measurement

The tapping point can be placed on either the upper half or the lower half (0° to 45° from centerline).

Selection depends on condensate discharge requirements and pipeline layout.

2. General Principles for Tapping Point Placement

2.1 Stable Flow Section

The pressure tapping should be located on a straight section of the pipeline with stable, fully developed flow.

Avoid positions near elbows, tees, valves, pumps, or any location prone to turbulence.

2.2 Relative Position to Temperature Sensor

If both pressure and temperature sensors are mounted on the same pipe:

The pressure tapping point must be upstream of the temperature tapping point to avoid thermal interference.

2.3 Tapping Port Insertion Depth

The end of the tapping port must not protrude into the pipeline.

It should be flush with the inner wall to avoid disturbing flow patterns.

3. Special Media and Pipe Orientation

3.1 Dirty, Dusty, or Sediment-Containing Fluids

For vertical pipelines:

The tapping port should be installed at an upward inclination angle ≥30° to prevent sediment buildup.

For horizontal pipelines:

Install the tapping port at a sharp angle in the direction of flow (acute downstream angle).

4. Sensor Installation Location Guidelines

4.1 Accessibility

The pressure sensor should be installed in a well-lit, accessible location for easy operation and maintenance.

Avoid areas exposed to excessive vibration, moisture, high temperatures, corrosive substances, or strong electromagnetic fields.

4.2 Distance from Tapping Point

The sensor should be located as close as possible to the tapping point to reduce transmission lag or signal distortion.

For low-pressure applications:

Ensure the sensor height matches the tapping point height, especially when measuring liquids or condensable gases.

4.3 Vertical Positioning Based on Medium

For gas measurements:

The sensor should be higher than the tapping point to allow condensate drainage.

For liquid or steam measurements:

The sensor should be lower than the tapping point to facilitate venting and condensate removal.

Conclusion

Following these guidelines ensures accurate pressure measurements and extends the service life of the pressure sensor. When designing or retrofitting pressure measurement systems, proper tapping point selection must be considered early in the engineering process. For complex or high-risk applications, consult your instrumentation provider or process control specialist.