1. Overview of Explosion-Proof Instrumentation

Explosion-proof instrumentation is a critical component in hazardous environments such as petrochemical plants, refineries, and chemical processing facilities. Due to their small size, instruments are often overlooked in explosion-proof assessments, yet their potential danger is equivalent to that of larger electrical equipment.

The most common explosion-proof types for instrumentation include:

Flameproof (Ex d): Suitable for Zone 1 and Zone 2 hazardous areas. Cannot be opened under power.

Increased Safety (Ex e): Primarily used in Zone 2, some in Zone 1. Allows power-on enclosure opening but not wiring disconnection.

Intrinsic Safety (Ex ia): Suitable for Zone 0, 1, and 2. Safe to open and disconnect under power.

Intrinsic Safety (Ex ib): For Zone 1 and Zone 2. Also safe for powered maintenance.

Pressurized (Ex p): Used in Zone 1 and Zone 2. Cannot be opened while powered.

Other less common types include oil immersion, encapsulation, and non-sparking designs.

2. Selection of Explosion-Proof Instruments

2.1 Based on Hazardous Area Zoning

Zone 0: Only Ex ia or specially designed S-type instruments are permitted.

Zone 1: Accepts all types except Ex n.

Zone 2: All explosion-proof types are permissible.

2.2 Based on Gas Group and Temperature Class

Instrument selection must consider the gas group (IIA, IIB, IIC) and temperature class (T1 to T6). These align with the ignition and explosion transmission characteristics of combustible gases and vapors.

| Temperature Class | Max Surface Temp | Typical Gases |

|---|---|---|

| T1 | 450°C | Methane |

| T2 | 300°C | Ethylene |

| T3 | 200°C | Gasoline, Diesel |

| T4 | 135°C | Acetaldehyde |

| T5 | 100°C | Benzene |

| T6 | 85°C | Hydrogen, Acetylene |

3. Key Considerations by Explosion-Proof Type

3.1 Flameproof Type (Ex d)

Enclosures must be tightly sealed at cable entries and terminal covers.

Power must be disconnected before opening.

3.2 Intrinsically Safe (Ex ia/ib)

Must use certified intrinsic safety barriers or isolators.

Most suitable for complex installations and critical safety areas.

3.3 Increased Safety (Ex e)

Emphasizes improved insulation and connection quality.

Maintenance may be performed live under controlled conditions.

3.4 Pressurized (Ex p)

Involves purging the enclosure with inert gas.

Requires pressure monitoring and failsafe mechanisms.

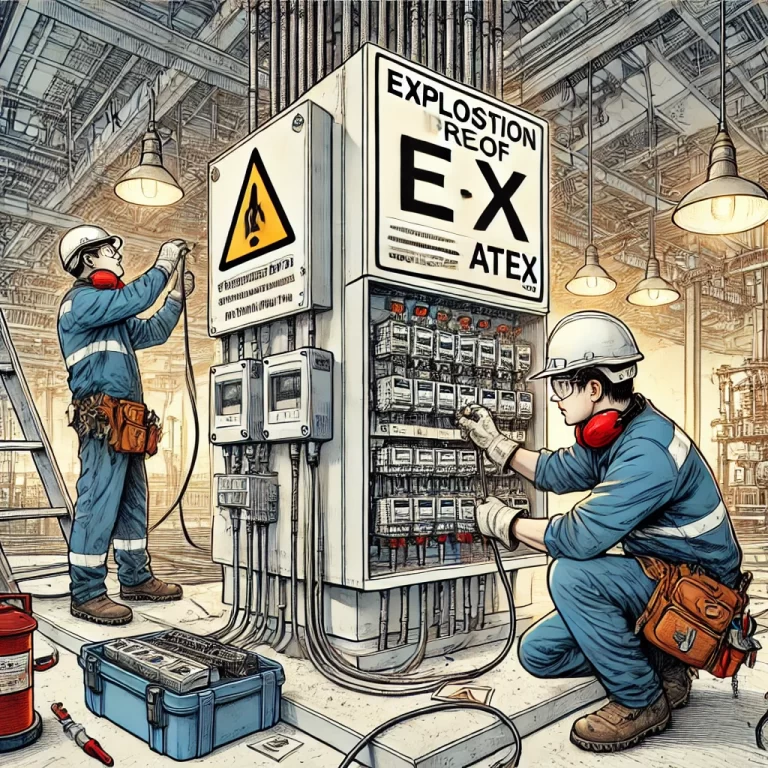

4. Installation Guidelines

Explosion-proof instruments and materials must bear nameplates and markings indicating compliance.

For Zone 1 areas, cables must be installed through galvanized steel conduits with threaded connections.

Segregation between different hazardous zones must include flame barriers, seals, or other physical isolation.

Within 0.45m of the instrument, explosion-proof seal fittings or packing must be used.

Flexible conduit may be used for final instrument connections, ensuring flamepath integrity.

5. Filling and Sealing Requirements

Filled Seal (Potting/Gel): Applied when cable diameters mismatch with sealing gland or when multiple cables enter through one fitting.

Prevents gas migration across hazardous zone boundaries.

6. Maintenance Best Practices

Regular inspection for physical damage, corrosion, humidity, vibration, and loose mounting.

Flameproof (Ex d) enclosures must never be opened while powered.

Tools and testing instruments must be certified for hazardous areas (Ex d or Ex ia).

Protect all flameproof threads and flanges from scratches, especially axial scratches.

Do not use sharp tools when removing rubber seals.

Follow assembly sequence and ensure all seals and fasteners are present and intact.

Replace corroded or aged components as needed.

Confirm restoration of explosion-proof integrity before putting the instrument back into service.

For detailed selection, installation, or compliance verification, always refer to local codes (e.g., IECEx, ATEX, GB3836) and consult qualified hazardous area professionals.