Exterior

The appearance of the flow meter should be complete and good, and the markings (nameplate, flow direction mark, explosion-proof mark, manufacturing measuring instrument license, etc.) should be correct, complete, and clear. There should be no scratches and other damage on the connecting surface of the external connection. Fasteners should be combined. It is firm and the coating has no defects such as damage and rust.

Level of accuracy

The accuracy grade of the flowmeter and the corresponding maximum allowable error are shown in Table 3. The maximum allowable error is expressed as a relative error.

| Table 3 Accuracy and corresponding maximum allowable error | |||||

| Level of accuracy | 0.5 | 1 | 1.5 | 2 | 2.5 |

| Maximum allowable error | ±0.5% | ±1% | ± 1.5% | ± 2% | ± 2.5% |

It is allowed to use the reference error to indicate the error of the flowmeter. At this time, the verification result is no longer expressed in the accuracy level, only the maximum error value is given, and FS is added after the maximum error, such as ±0.5%FS. When using the reference error, the flowmeter The maximum allowable error should meet the requirements of Table 3.

Repeatability

The repeatability error of the flowmeter shall not exceed 1/3 of the absolute value of the maximum allowable error.

Dead zone

The dead zone of the flowmeter should not exceed 2/5 of the absolute value of the maximum allowable error.

Initial drift

The initial drift of the flowmeter should not exceed the absolute value of the maximum allowable value.

Impact of output load changes

When the load resistance changes within the specified range of not less than 500Ω, the output change of the flowmeter does not exceed the absolute value of the maximum allowable error.

Influence of environmental temperature changes

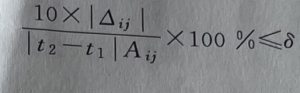

When the ambient temperature is within the range specified in 6.1 and the test temperature is changed in order of 20℃, 40℃, 55℃, 70℃, 20℃, 0℃, -10℃, -25℃, -35℃, 20℃, the two The output change of the flowmeter of two adjacent points meets the requirements of formula (3):

Influence of power supply changes

When the voltage at the meter terminal of the flowmeter changes within the range specified in DC 24, the change in the output of the flowmeter shall not exceed 1/3 of the absolute value of the maximum allowable error.

Impact of power interruption

After the continuous test of power supply cut off and energized, the stable change of flowmeter output shall not exceed 1/3 of the maximum allowable absolute value.

The power interruption time can be selected as 5ms, 20ms, 100ms, 200ms, 500ms.

Influence of external magnetic field

Under the influence of an external magnetic field with a magnetic intensity of 400A/m and a frequency of 50Hz, the output change of the flowmeter should not exceed the absolute value of the maximum allowable error limit.

Insulation resistance

When the flowmeter is powered off, the insulation resistance between each power terminal and the metal shell after a short circuit is not less than 20MΩ, and the insulation resistance after the damp heat test is not less than 2MΩ.

Humidity and heat resistance

The flowmeter should be kept for at least 48h under the conditions of a temperature of 40℃+-2℃ and relative humidity of 93%+-3%. The output change of the flowmeter during the test shall not exceed 1.5 times the absolute value of the maximum allowable error. The insulation resistance shall be Meet the requirements of not less than 20MΩ, and the insulation resistance after the damp heat test is not less than 2MΩ. Then, after placing it in the reference atmosphere for no less than 24h, the error of the flowmeter should still meet the requirements of the following.

| Table 3 Accuracy and corresponding maximum allowable error | |||||

| Level of accuracy | 0.5 | 1 | 1.5 | 2 | 2.5 |

| Maximum allowable error | ±0.5% | ±1% | ± 1.5% | ± 2% | ± 2.5% |

Communication

For flow meters that output digital signals, the communication protocol should comply with the corresponding standards.

Explosion-proof performance

The explosion-proof performance of the flow meter meets the requirements of GB3836.

Degree protection of the shell

The enclosure protection level of the flowmeter meets the requirements of GB4208.

Compressive strength

1) When the nominal pressure is less than 10.0 MPa, the pressure-bearing part of the flowmeter should be able to withstand 1.5 times the nominal pressure for 5 minutes without leakage or damage.

2) When the nominal pressure is greater than 10.0 MPa, the pressure-bearing part of the flowmeter should be able to withstand 1.25 times the nominal pressure for 5 minutes without leakage or damage.

Airtightness

Carry out the airtightness test at 1.05 times the nominal pressure and keep it for 5 minutes without leakage or damage.