1. Introduction

The submersible level transmitter is designed for accurate measurement of liquid levels in various industrial applications. Its robust structure and optimized probe design ensure reliable operation in both static and dynamic liquid conditions. The device operates by sensing the hydrostatic pressure exerted by the liquid column and converting it into a standard electrical signal for remote monitoring and control.

2. Design Features

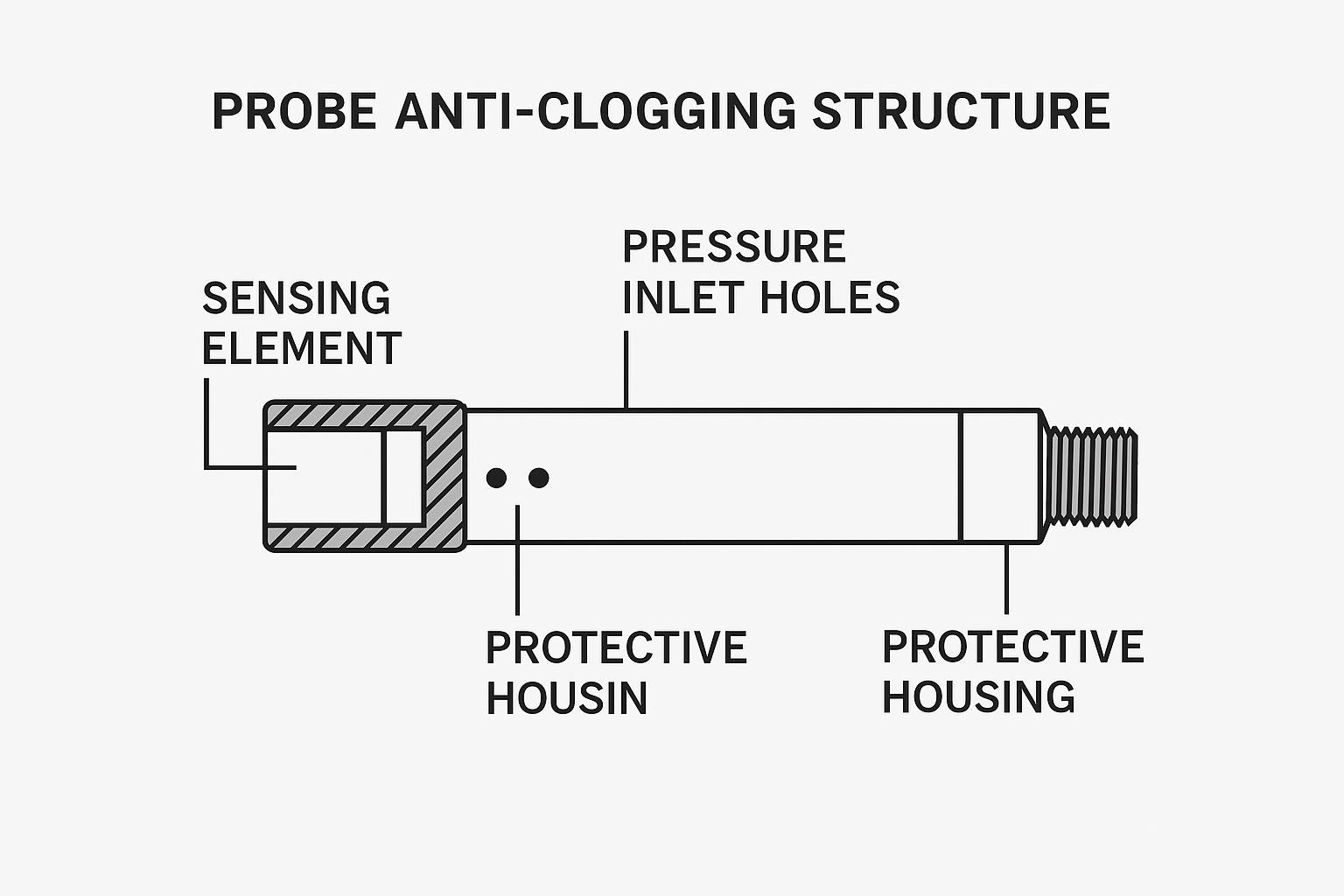

Probe Structure:

The transmitter features a cylindrical probe with a sealed threaded end. The sensing element is located at one end, while the other end is equipped with a power supply and signal cable.Anti-Clogging Design:

The probe is designed to be fully immersed in the measured medium. To prevent blockages in the pressure inlet, the sensing end is shielded, and the liquid enters through precision-positioned inlet holes. The location and angle of these holes are optimized through extensive testing.Durable Materials:

Materials are selected according to the measured medium to ensure corrosion resistance and long service life.

3. Installation Methods

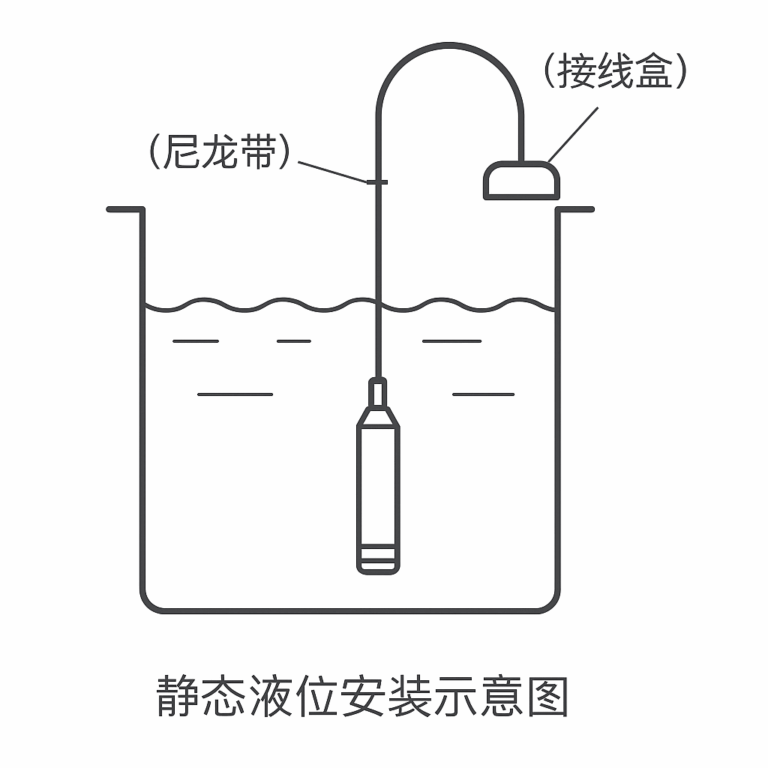

3.1 Static Liquid Installation

For open tanks or containers with stable liquid levels:

Place the probe directly at the bottom of the container.

Secure the cable (and junction box, if applicable) at the container opening using a nylon strap or an adjustable tripod mounting bracket.

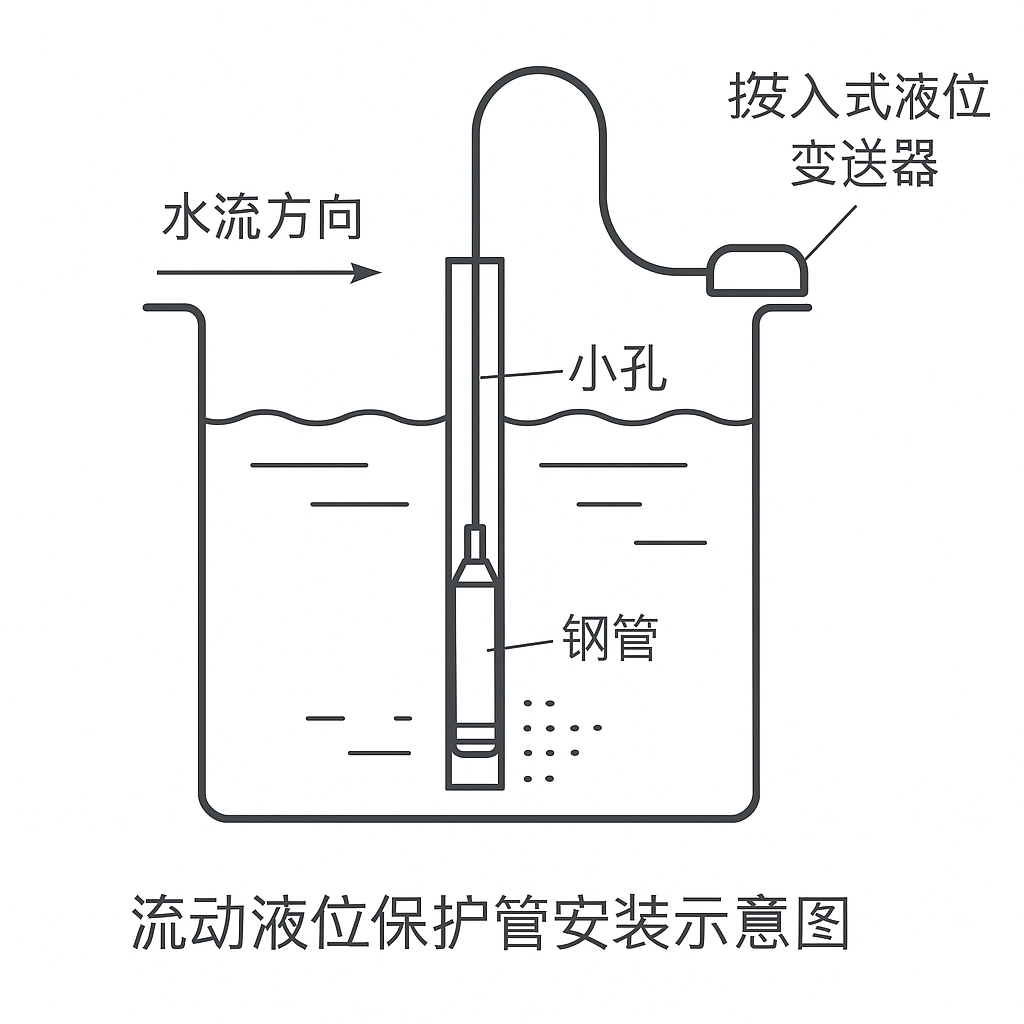

3.2 Flowing Liquid Installation

For applications where the liquid is in motion:

Protective Pipe Method: Insert a steel pipe with an internal diameter larger than the probe into the liquid. Drill multiple small holes on the side opposite to the flow direction at various heights, allowing liquid to enter while minimizing turbulence.

Damping Device Method: Install a damping device at the bottom to filter out sediment and reduce dynamic pressure and wave interference.

4. Installation Precautions

The probe must be installed vertically.

Avoid positioning near liquid inlets, outlets, or agitators.

In high-vibration environments, wrap the transmitter cable with a steel wire to reduce mechanical stress and prevent cable breakage.

Before installation, ensure:

The wetted parts’ material is compatible with the measured medium.

The measured medium will not block the pressure inlet.

The possible static pressure does not exceed the transmitter’s measurement range.

5. Maintenance Tip

Regularly inspect the pressure inlet for debris or sediment buildup, especially in environments with suspended solids. Clean using mild water flushing or manufacturer-recommended methods.