Stud bolts—also referred to as stud screws or threaded rods—are essential fasteners used for securing components in a wide range of industrial applications. This guide provides a comprehensive overview of stud bolts, covering their structure, selection criteria, common uses, surface treatments, anti-loosening strategies, and maintenance procedures.

1. What Is a Stud Bolt?

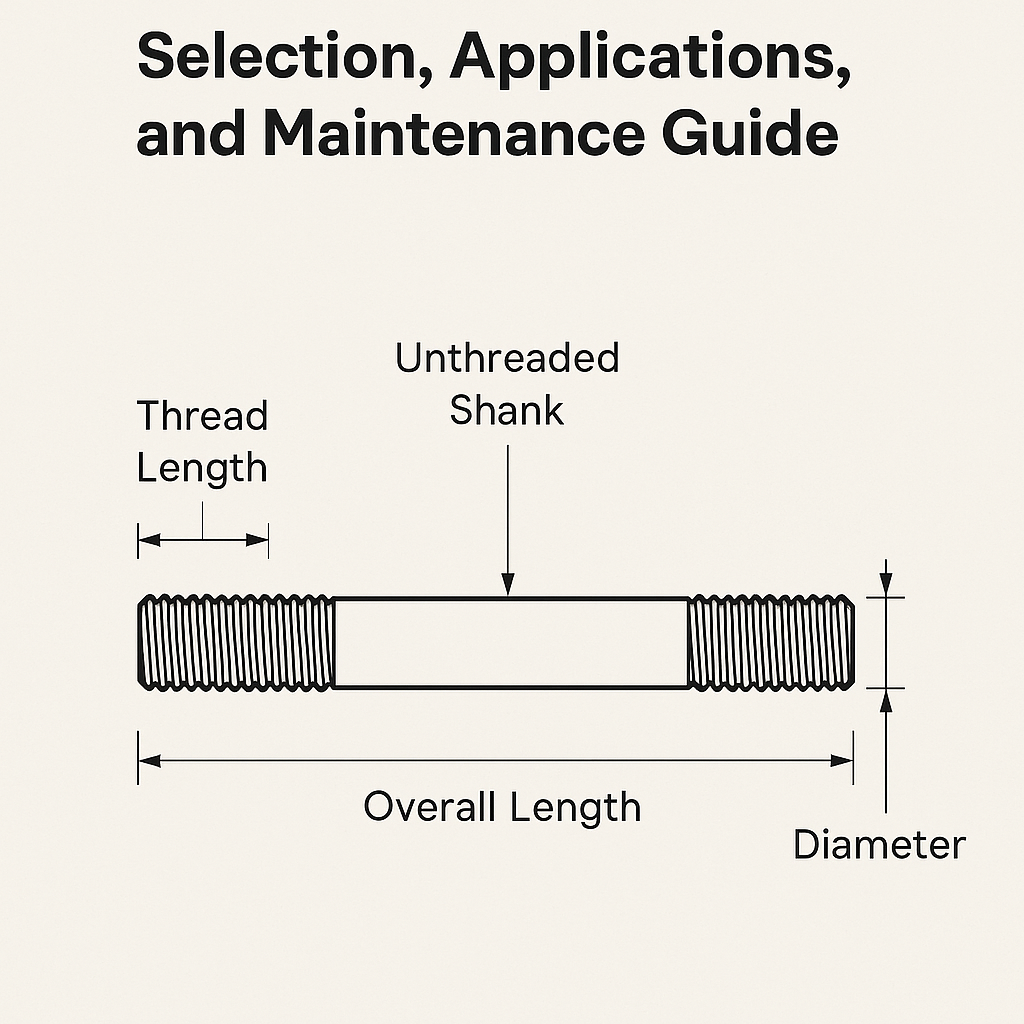

A stud bolt is a threaded fastener with threads on both ends and an unthreaded shank in the middle. Unlike standard bolts, it lacks a head and is typically used where components need frequent assembly and disassembly or where space constraints prevent the use of full-size bolts. The most common form features equal-length threads on each end with a plain center section.

2. Common Applications

Stud bolts are widely used in:

Heavy Equipment: For mounting components like sight glasses, mechanical seal bases, and gearboxes.

Thick Connections: When component thickness exceeds standard bolt lengths.

Structural Installations: In steel structures, concrete roof frames, and monorail hangers where hex bolts are impractical.

3. Specification Marking Example

Stud bolts are standardized under specifications like GB 901.

Example:

A stud bolt with thread size M12, length 80 mm, and strength grade 4.8 would be marked:GB 901 M12×80

4. Anti-Loosening Considerations

Stud bolts must maintain a secure connection under:

Vibration

Thermal cycling

Load fluctuations

These factors reduce friction and clamping force, increasing the risk of loosening or complete failure. To mitigate this:

Use lock nuts or spring washers

Apply thread-locking compounds

Consider preloading techniques

5. Surface Treatment Options

Surface finishing enhances corrosion resistance and thread functionality. Common treatments include:

Electroplating (e.g., zinc, nickel)

Phosphating

Black oxide coating

Non-electrolytic zinc flake coatings

For industries like automotive, aerospace, and telecommunications, where both corrosion protection and thread interchangeability (fit accuracy) are critical, specific plating standards must be followed.

6. Manufacturing Process Overview

Basic stud bolt production includes:

Straightening (Bar Drawing): Correcting material deformation.

Cutting: Using a cutting machine to specified lengths.

Thread Rolling: Threads are formed on both ends using a thread rolling machine.

Additional steps such as heat treatment, precision machining, or special coating may be applied based on requirements.

7. Maintenance and Inspection Guidelines

Stud bolts are subject to wear and fatigue over time. Recommended practices include:

Routine Inspection:

Check for cracks, thread deformation, or denting.

Measure thread pitch and ensure no irregularities.

Replacement Criteria:

Replace if wear is visible, or if thread geometry is distorted.

Always replace in pairs with matching connecting rods or nuts.

Installation Torque:

Use a calibrated torque wrench and follow specified torque ratings.

Critical Applications:

For engine or rotating equipment, check crankcase parts like oil pans and connecting rod caps.

If abnormal noise or instability occurs, stop operation immediately and inspect.

8. Summary

Stud bolts offer a reliable and replaceable fastening solution for heavy-duty and high-maintenance applications. By understanding their structure, applications, and maintenance requirements, engineers can ensure longer service life, better safety, and easier repairs in complex mechanical systems.