1) Why steam flow measurement matters

Steam accounts for a large share of plant energy. Choosing the right flowmeter drives accuracy, stability, and pressure/energy efficiency.

This guide covers seven common meter types: Differential Pressure (DP/orifice), Vortex, Mechanical Rotary (paddle/turbine), Linear Orifice Plate, V‑Cone, Elbow (bend tube), and Averaging Pitot Tube (APT). Each section lists pros/cons, installation notes, and where each excels.

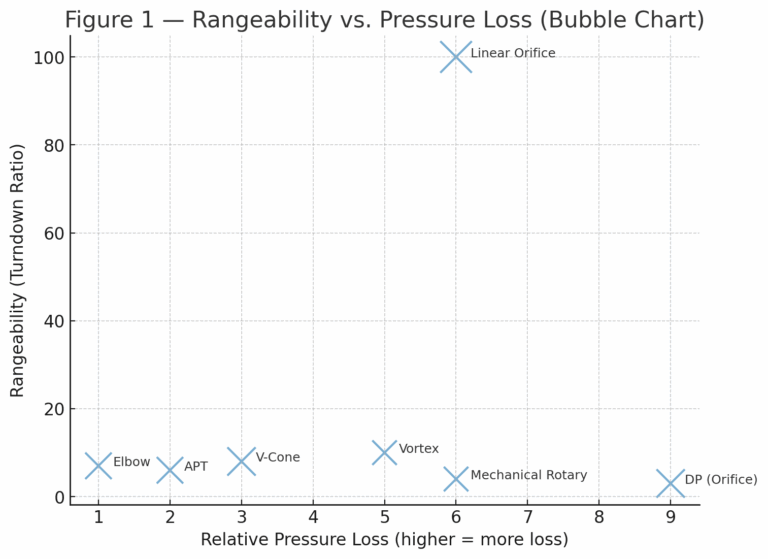

2) Quick comparison (at a glance)

| Meter type | Turndown (relative) | Pressure loss (relative) | Temperature tolerance | Vibration sensitivity | Straight‑run need | Maintenance | Notes |

|---|---|---|---|---|---|---|---|

| DP (orifice) | Low (≈3:1) | High | Excellent | Low | High | Low | Proven for high‑T/high‑P steam; needs P/T compensation |

| Vortex | Medium–High (≈10:1) | Low–Medium | Up to ~300 °C typical | High (avoid vibration) | Medium | Low | Clean, dry steam preferred |

| Mechanical rotary (paddle/turbine) | Low–Medium | Medium | Moderate | Medium | Medium | Medium | Simple mechanics; budget‑friendly |

| Linear orifice plate (variable‑area DP) | Very High (~100:1) | Medium | Moderate | Low | Low | Medium | Moving parts; water calibration recommended |

| V‑Cone | Medium | Low (≈1/3 orifice) | High (with impulse‑line protection) | Low | Very Low | Low | Compact install; still needs P/T compensation |

| Elbow (bend tube) | Medium (with DP cell) | None (uses existing bend) | High | Low | N/A | Very Low | Energy‑saving; requires high‑grade DP transmitter |

| Averaging Pitot Tube (APT) | Medium | Low | High | Low | Medium | Low | Insertion probe; watch for port fouling |

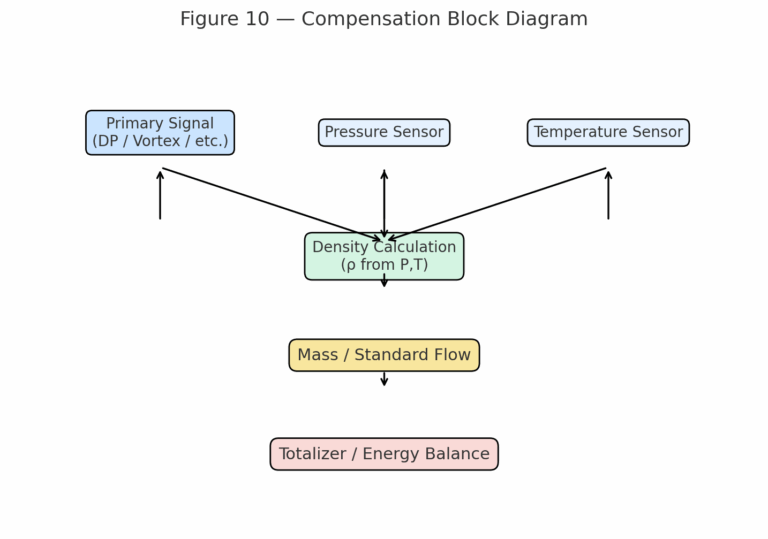

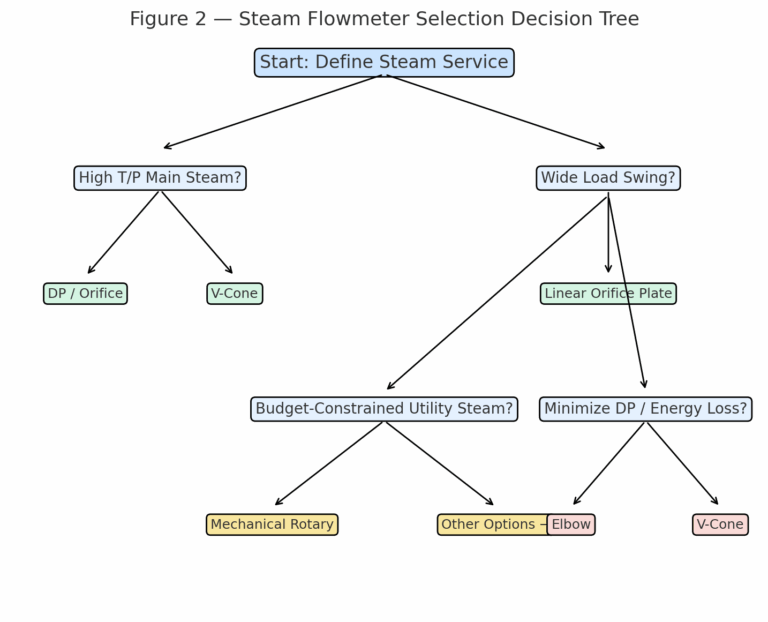

3) Meter selection flow (practical)

High‑T/high‑P main steam? → DP/orifice or V‑Cone.

Very wide load swing (startup → turndown)? → Linear orifice plate.

Budget‑constrained utility steam? → Mechanical rotary.

Minimize energy loss/DP? → Elbow or V‑Cone.

Vibration present or wet steam likely? → Avoid Vortex; consider DP/V‑Cone/APT.

4) Technology notes — pros, cons & installation

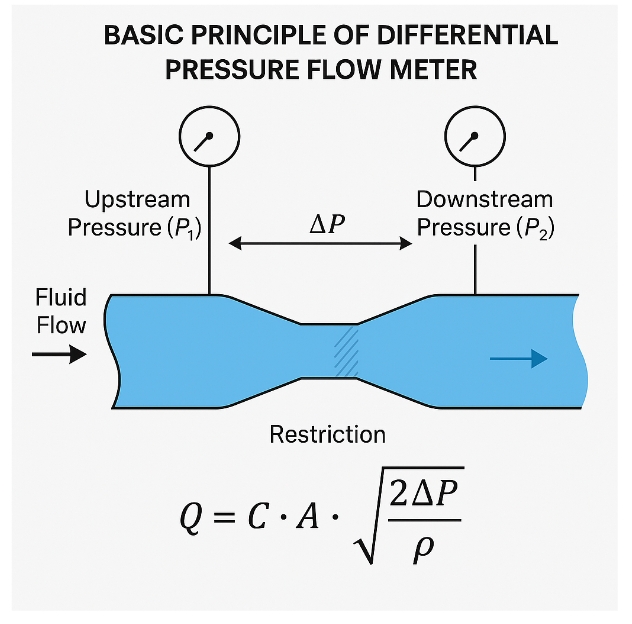

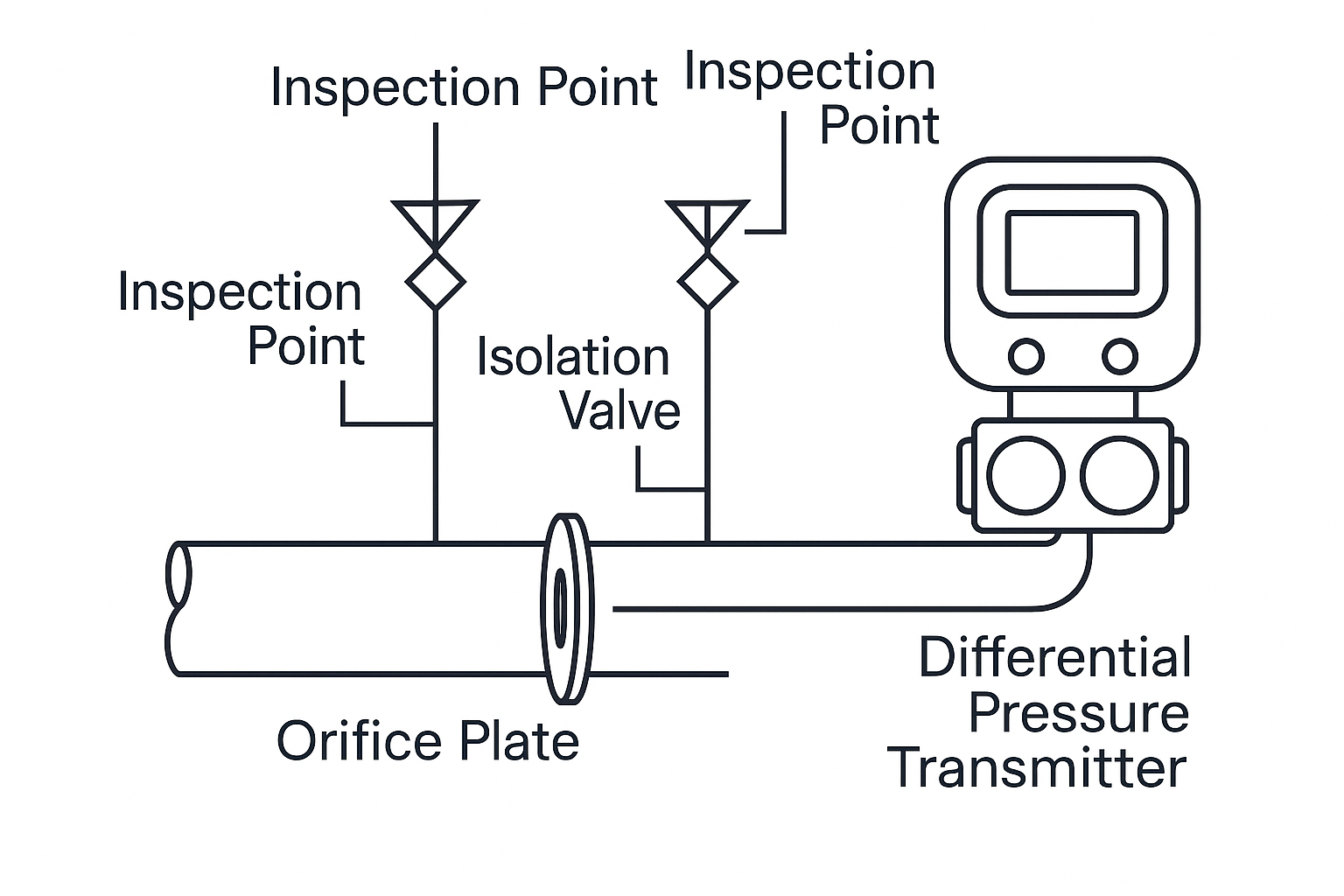

4.1 Differential Pressure (DP / Orifice)

Pros

• Handles high temperature/pressure steam

• Simple, rugged, widely supported

• No periodic factory calibration in many services

Cons

• Low turndown (≈3:1)

• High permanent pressure loss

• Needs careful upfront sizing and straight‑run

Install & integration

• Provide adequate upstream/downstream straight‑run

• Use proper pressure taps (corner/flange/D‑D/2)

• Always include P/T compensation (DP + P + T)

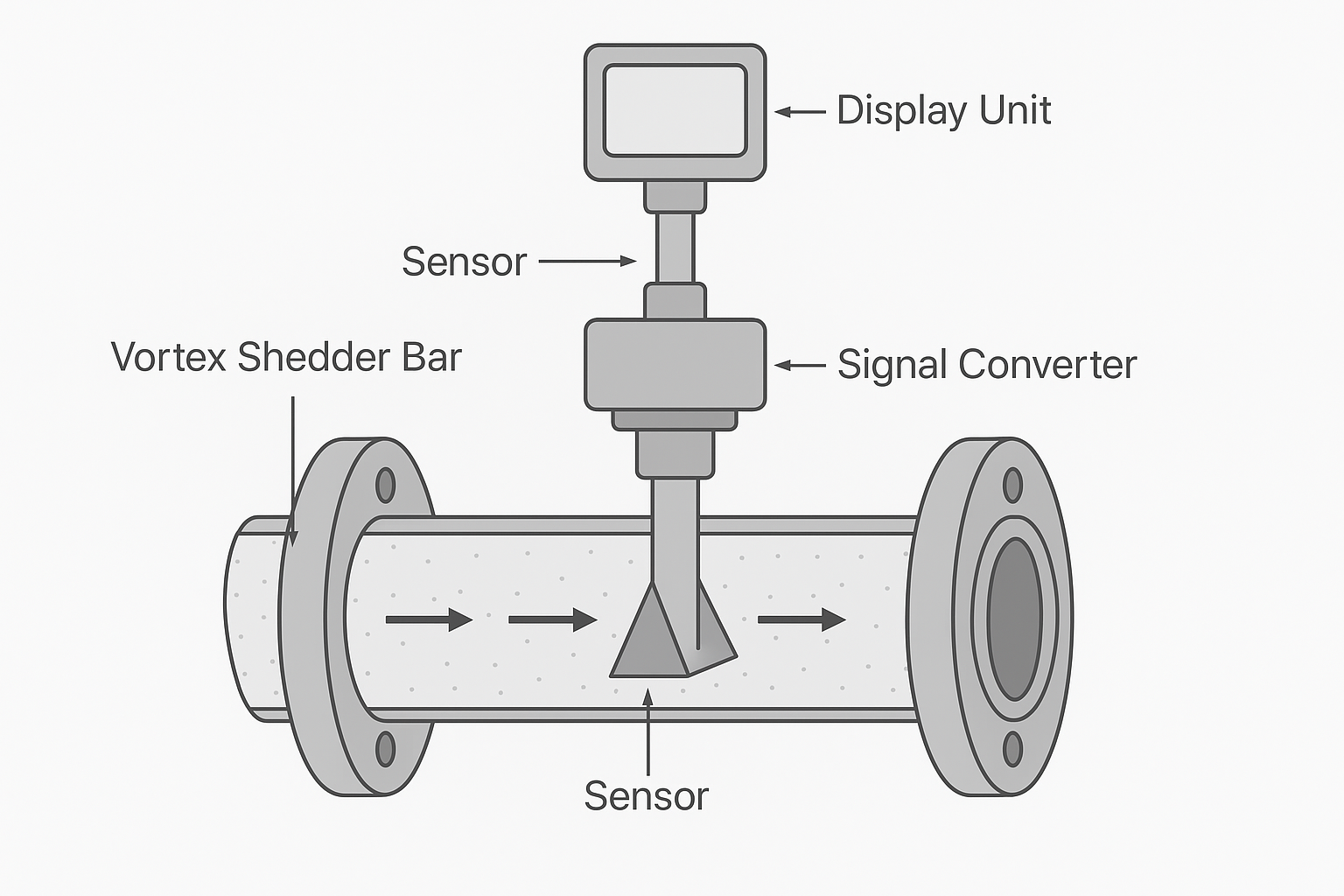

4.2 Vortex shedding

Pros

• Turndown up to ~10:1

• Lower pressure loss than orifice

• Straightforward installation

Cons

• Sensitive to piping vibration

• Typical temperature limit about 300 °C

• Wet steam can destabilize signal

Install & integration

• Ensure rigid piping support; avoid vibration sources

• Use separators if wet steam is expected

• Verify straight‑run; follow maker’s K‑factor guidance

4.3 Mechanical rotary (paddlewheel/turbine style)

Pros

• Durable mechanical structure

• Works without external power (some designs)

• Cost‑effective for utility monitoring

Cons

• Typically horizontal install only

• Accuracy modest vs. DP/Vortex

• Narrow pipe‑size coverage, check model limits

Install & integration

• Maintain clean steam and proper filtration

• Verify direction/orientation arrows

• Periodic inspection for deposits and wear

4.4 Linear Orifice Plate (variable‑area DP device)

Pros

• Very wide turndown (~100:1)

• Strong anti‑vibration performance

• Lower straight‑run demand

Cons

• Water calibration recommended

• Moving parts require periodic checks

• Temperature changes may shift characteristics

Install & integration

• Plan for routine inspection of movable elements

• Maintain consistent thermal environment

• Integrate P/T compensation for mass/standard flow

4.5 V‑Cone

Pros

• Low DP loss (≈1/3 of orifice) → energy saving

• Very low straight‑run requirements

• Compact; often supplied with integral valve manifold

Cons

• Superheated steam needs condensers/impulse‑line protection

• Still requires P/T compensation

• Use heat‑shielded impulse lines at high temperature

Install & integration

• Follow manufacturer’s minimal straight‑run

• Provide condensate pots/leg protection

• Calibrate or verify K‑factor as per datasheet

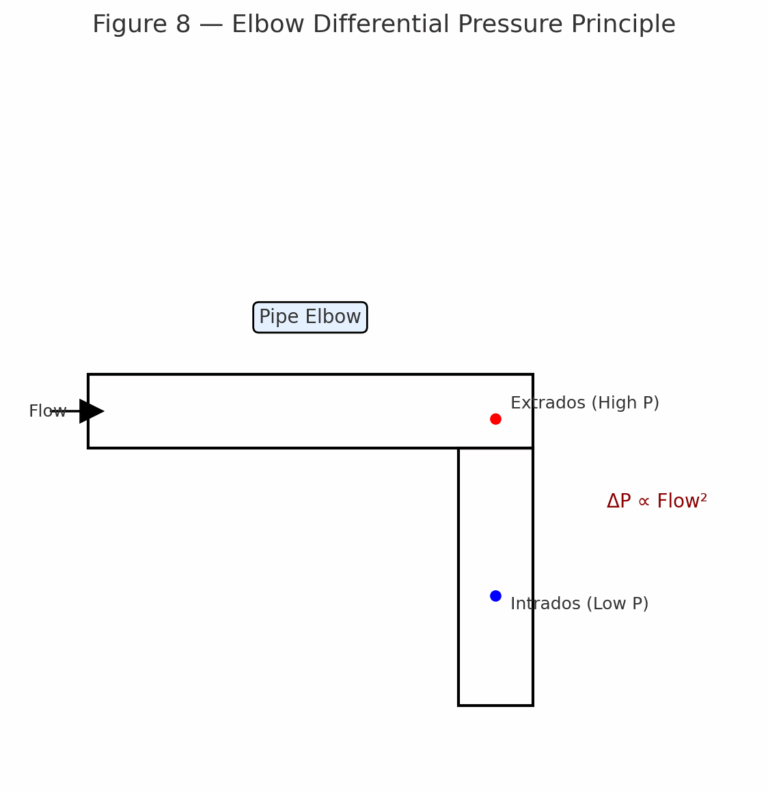

4.6 Elbow (bend‑tube) with DP cell

Pros

• Zero added pressure loss (uses existing elbow)

• Near‑zero maintenance

• Rugged; suitable for high‑T/high‑P steam

Cons

• Small DP → requires a high‑performance DP transmitter

• Needs density/temperature/pressure compensation

• Careful tap symmetry and orientation required

Install & integration

• Drill taps at intrados/extrados symmetry points

• Use matched impulse‑line lengths

• Commission with verified P/T sensors

4.7 Averaging Pitot Tube (APT)

Pros

• Works for gas/liquid/steam

• Simple insertion and retrofit

• Handles high temperature/pressure

Cons

• Micro‑DP measurement requires precise transmitter

• Port fouling risk; maintain purge

• Sensitive to non‑uniform velocity profile

Install & integration

• Place per maker’s insertion depth/orientation

• Provide purge ports; periodic cleaning

• Apply P/T compensation and profile correction as needed

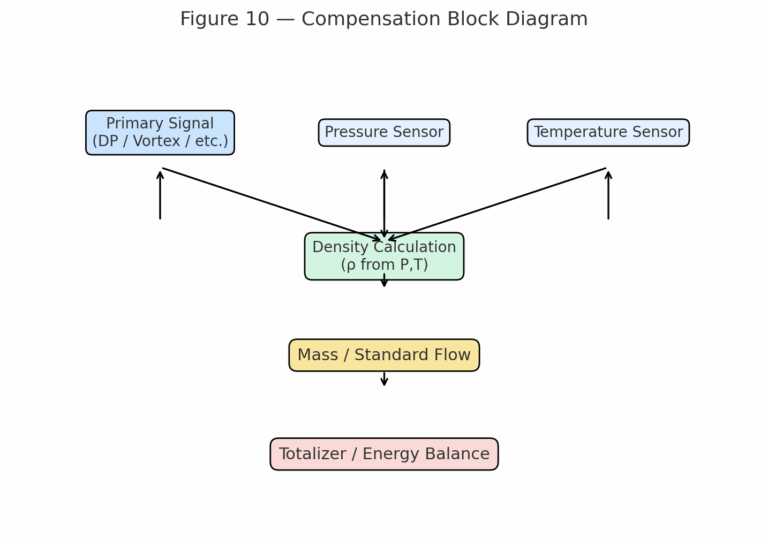

5) Compensation & data quality

Accurate steam mass/standard flow requires DP (or other primary signal) + absolute pressure + temperature. Use matched sensors, short impulse lines, and condensation pots where needed. Validate with site acceptance tests and trending.

6) “Special cases”: thermal mass flow

Thermal mass meters are not mainstream for steam, but in special monitoring (very low flow, leak detection) they can help. Watch out for temperature drift and contamination.

7) Field checklist (ready to use)

Define service: pressure/temperature range, dryness fraction, and expected turndown.

Map constraints: straight‑run, vibration, tapping ability, electrical class.

Choose technology using Section 3 decision tree.

Add compensation: P+T for mass flow.

Commission: leak‑tight impulse lines, proper condensate legs, transmitter range, zero/span.

Trend and verify: compare against energy balance and boiler feed.