Flow measurement is a critical function in process industries, and differential pressure (DP) flow meters remain among the most widely used devices. Within this category, two commonly used types are the standard orifice plate and the balanced flow meter (often referring to a multi-hole balanced orifice plate). While both rely on the same working principle—creating a pressure drop to calculate flow—they differ significantly in structure, performance, and application.

In this article, we’ll explore the key differences between these two technologies and guide you on how to choose the right one for your application.

1. Working Principle Overview

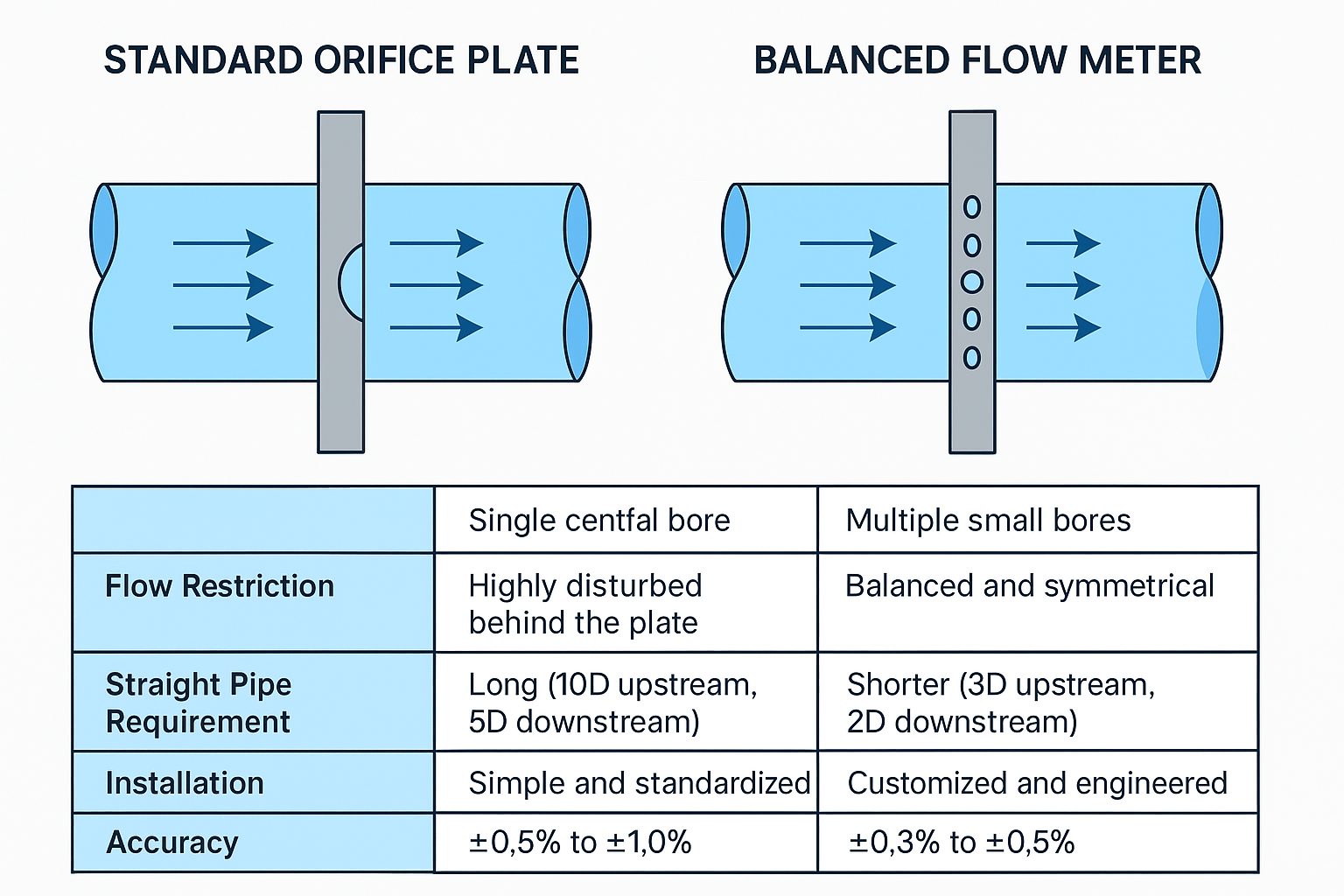

Both instruments operate based on Bernoulli’s principle, where a constriction in the pipeline causes a pressure drop that correlates with the fluid flow rate. However:

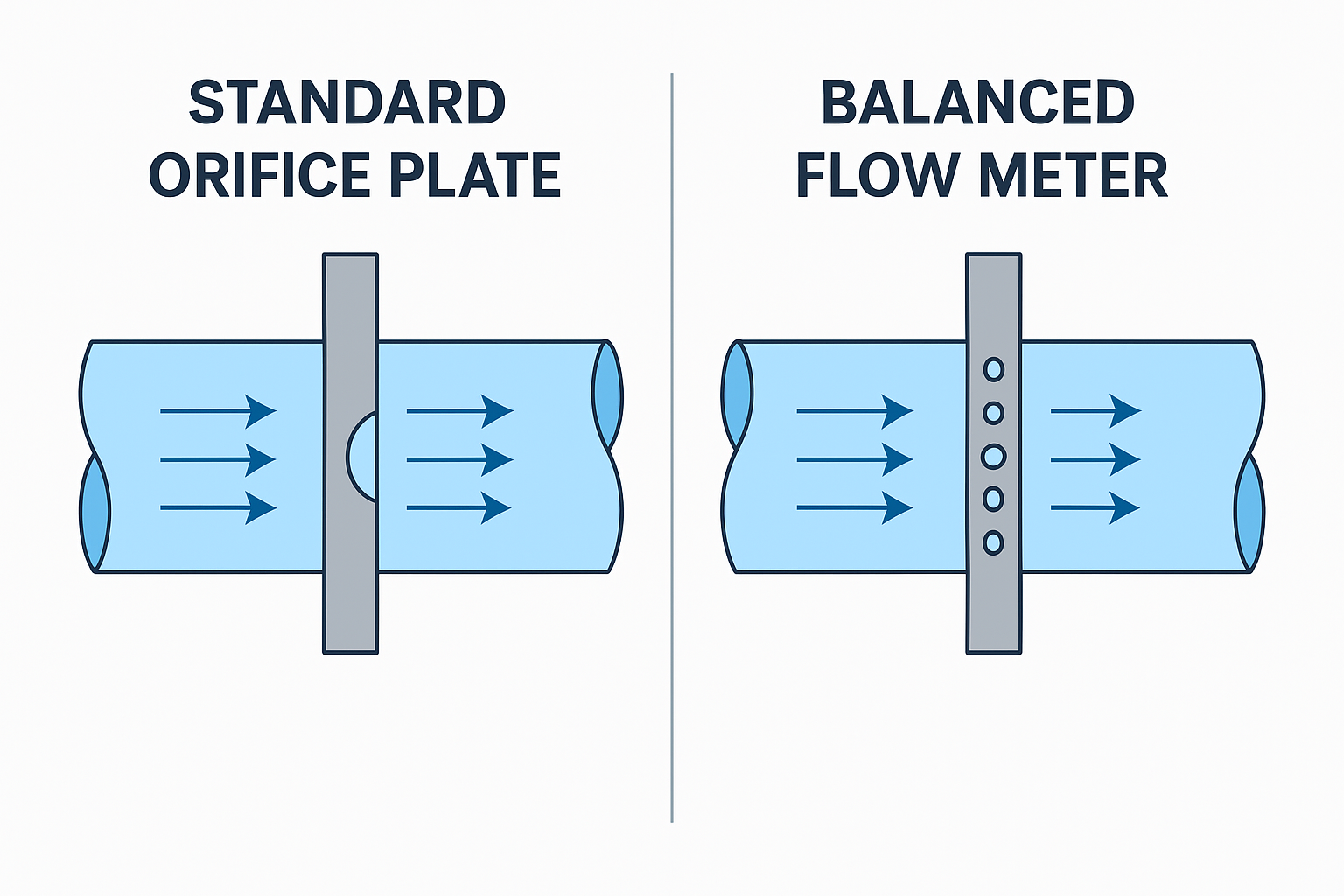

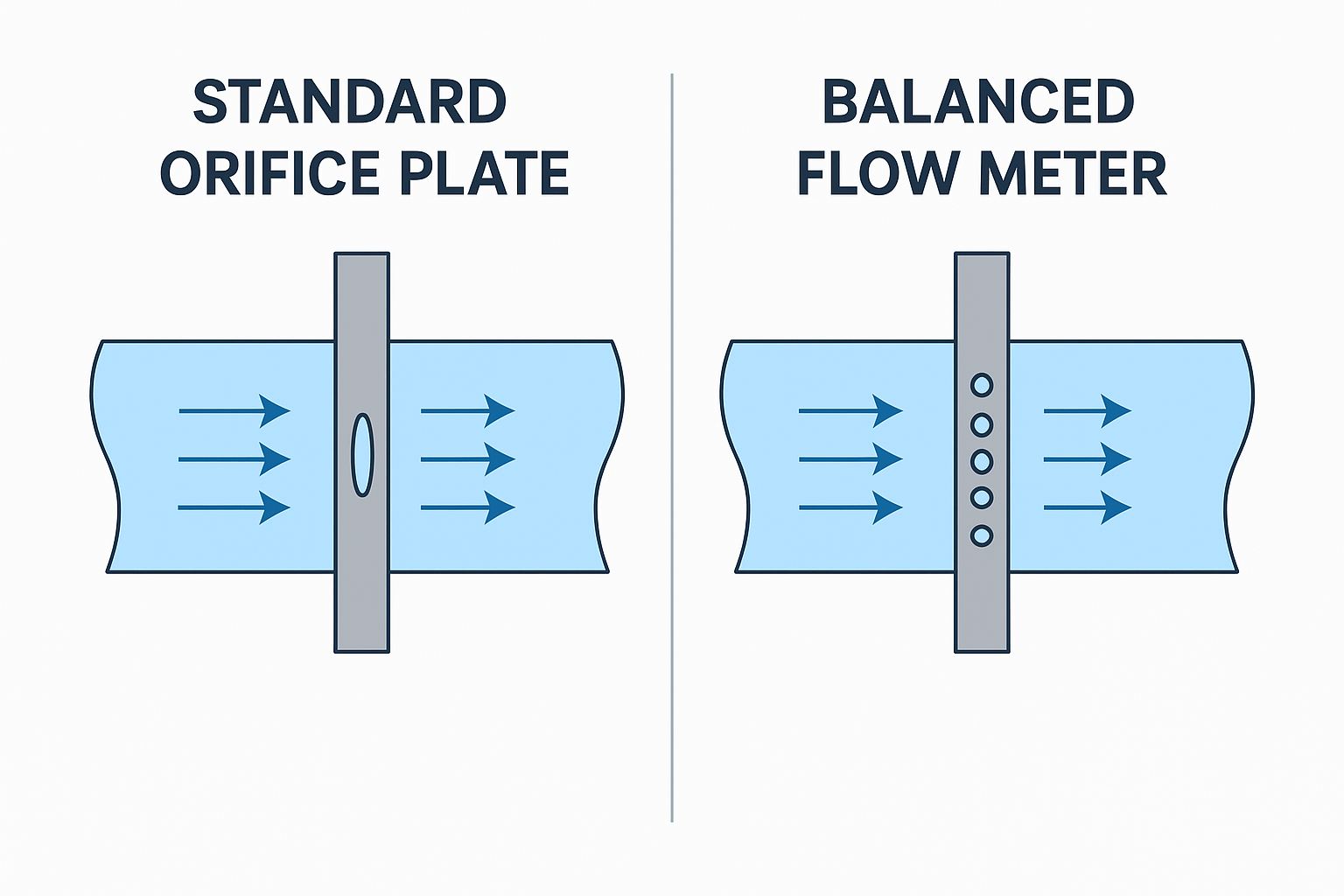

A standard orifice plate uses a single central hole with a sharp edge to create the pressure drop.

A balanced flow meter uses multiple small holes symmetrically arranged to balance the flow field and reduce turbulence.

2. Structural Comparison

| Feature | Standard Orifice Plate | Balanced Flow Meter |

|---|---|---|

| Flow Restriction | Single central bore | Multiple small bores |

| Flow Pattern | Highly disturbed behind the plate | Balanced and symmetrical |

| Straight Pipe Requirement | Long (10D upstream, 5D downstream) | Shorter (3D upstream, 2D downstream) |

| Installation | Simple and standardized | Customized and engineered |

3. Performance Characteristics

| Parameter | Standard Orifice Plate | Balanced Flow Meter |

|---|---|---|

| Accuracy | ±0.5% to ±1.0% | ±0.3% to ±0.5% |

| Rangeability (Turndown Ratio) | Typically 3:1 to 5:1 | Up to 10:1 or more |

| Pressure Loss | Higher | Lower |

| Flow Stability | Sensitive to upstream disturbances | Highly stable under fluctuating conditions |

| Resistance to Blockage | Susceptible to clogging | Improved anti-clogging capability due to distributed holes |

4. Typical Applications

| Industry | Standard Orifice Plate | Balanced Flow Meter |

|---|---|---|

| Power Generation | ✔️ Steam, condensate lines | ✔️ Complex gas and water circuits |

| Chemical & Petrochemical | ✔️ Clean liquids and gases | ✔️ Viscous fluids, slurries, wet gases |

| Oil & Gas | ✔️ Fiscal metering | ✔️ Multiphase flow, dirty gas, flare systems |

| Water Treatment | ✔️ Process water | ✔️ Raw water, effluent with solids |

| General Utilities | ✔️ Compressed air, nitrogen | ✔️ Mixed utility streams |

5. Cost and Maintenance Considerations

Standard orifice plates are cost-effective and easy to replace but have higher permanent pressure loss and are prone to wear over time.

Balanced flow meters require a higher upfront investment but offer long-term energy savings, reduced maintenance, and higher measurement reliability.

6. Which One Should You Choose?

| Your Priority | Best Choice |

|---|---|

| Low Cost, Standard Flow | Standard Orifice Plate |

| High Accuracy & Efficiency | Balanced Flow Meter |

| Short Pipe Runs | Balanced Flow Meter |

| Clean Media | Standard Orifice Plate |

| Dirty or Wet Gas | Balanced Flow Meter |

| Energy Savings | Balanced Flow Meter |

Conclusion

Both standard orifice plates and balanced flow meters have their place in industrial flow measurement. The choice ultimately depends on the fluid characteristics, installation conditions, required accuracy, and budget. While orifice plates remain a reliable and well-understood solution, balanced flow meters are gaining popularity in challenging applications where stability, precision, and lower pressure loss are essential.

Need help choosing the right flow meter for your project? Contact our team for expert guidance and product recommendations tailored to your industry.