1. Installation Orientation and Mechanical Requirements

Vertical Pipeline Installation:

Temperature instruments mounted on vertical pipelines must be installed at a 45° angle against the flow direction to ensure accurate temperature sensing and avoid measurement distortion caused by stagnant flow zones.Mounting Nozzle Length Standard:

For flange ratings 150LB, use a 150 mm long nozzle.

For 300LB and above, use a 230 mm long nozzle.

These lengths ensure adequate sensor insertion depth and maintain sealing integrity.

Expansion Pipe Requirement:

If the main process pipeline has a diameter smaller than DN100 (4 inches), an expansion section of DN100 must be added at the installation point to reduce flow disturbance and allow correct probe insertion.

2. Flange and Fastening Inspection

Bolt Protrusion:

Flange connection bolts must protrude 5–10 mm beyond the nut to allow for proper engagement and torque verification.Explosion-Proof Cable Gland:

Ensure the explosion-proof cable gland is properly installed and securely tightened. The gland must be oriented downward or sideways, not facing upward, to prevent water ingress and maintain explosion-proof integrity.

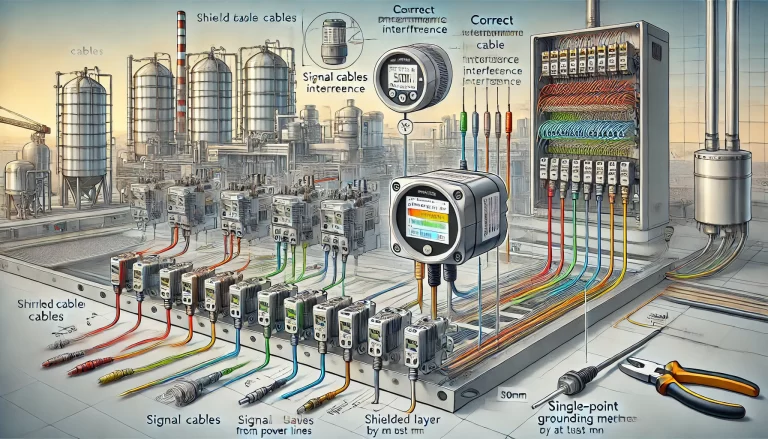

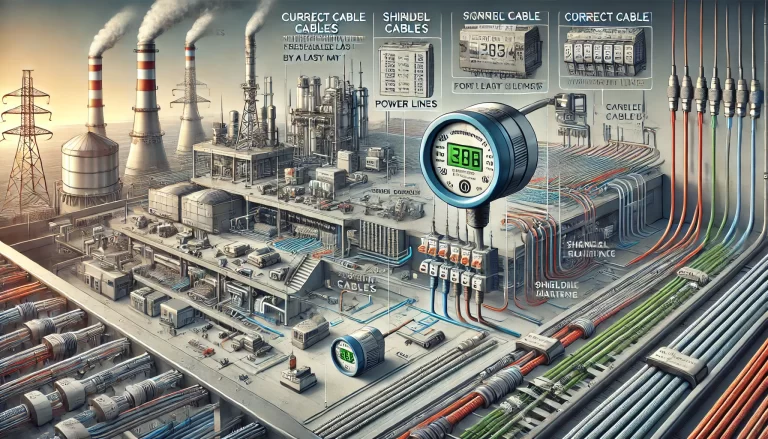

3. Electrical Wiring and Shielding

Cable Termination:

All electrical connections should follow wiring standards.

Cable ends must be properly crimped with pre-insulated terminals, and terminal screws must be securely tightened.

Shield Layer Handling:

Check for exposed shielding layers, which must be avoided.

Ensure the shield is correctly grounded at a single point to prevent electromagnetic interference (EMI).

4. Instrument Placement Relative to Other Devices

Relative Positioning with Pressure Instruments:

When a temperature sensor is installed on the same pipe section as a pressure instrument, and the distance between them is short, the temperature instrument must be positioned downstream of the pressure tapping point. This ensures accurate readings and prevents cross-interference.

Inspection Checklist Summary

| Item | Inspection Criteria |

|---|---|

| Installation angle | 45° against flow on vertical pipes |

| Nozzle length | 150 mm (150LB), 230 mm (≥300LB) |

| Expansion pipe | Required if pipe < DN100 |

| Flange bolts | Bolt end protrusion 5–10 mm beyond nut |

| Cable gland orientation | Downward or sideways; must be explosion-proof and tightened |

| Cable termination | Secure crimping with insulated terminals; no loose screws |

| Shield grounding | No exposed shields; grounded properly |

| Instrument positioning | Downstream of pressure sensor if installed nearby on same pipe |