Executive Summary

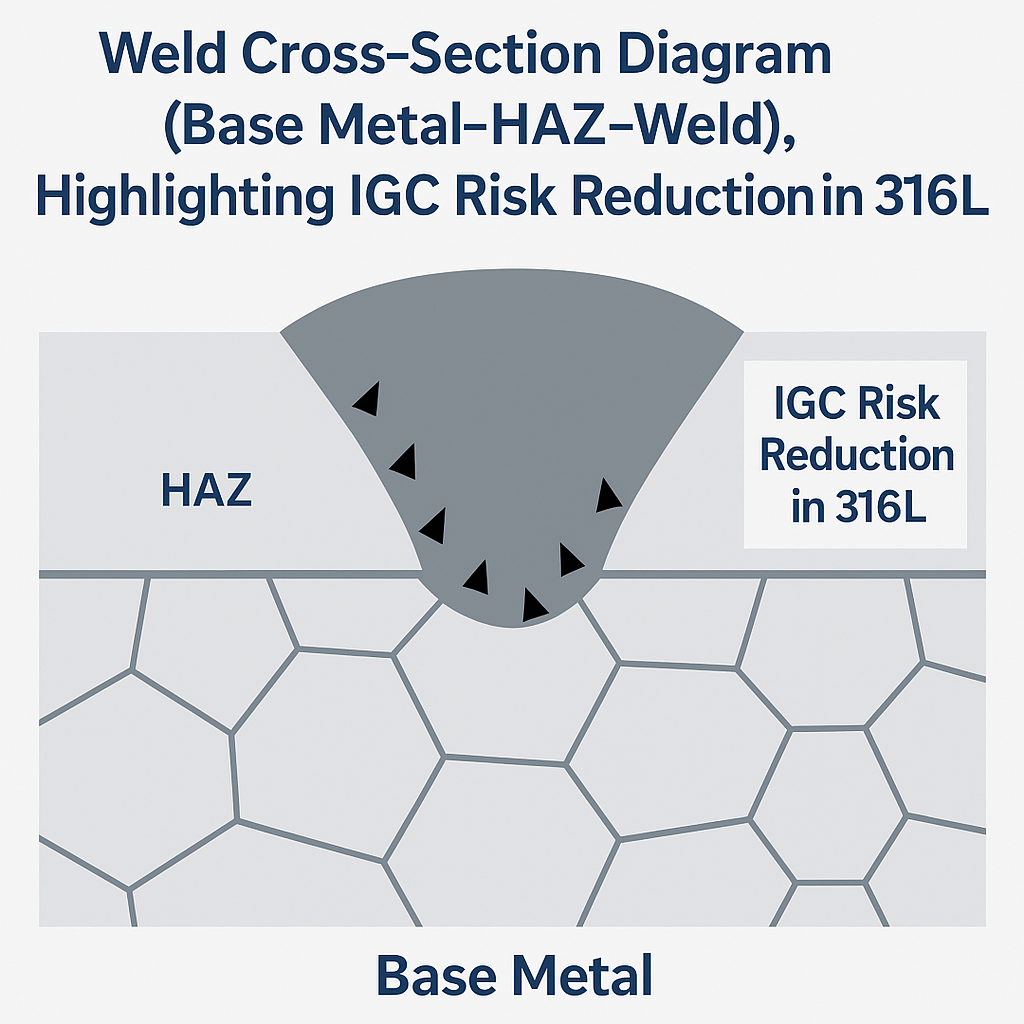

Main metallurgical difference: 316L has lower carbon (≤0.03%) than 316 (≤0.08%), which reduces sensitization during welding and thermal exposure (≈450–850 °C) and helps prevent intergranular corrosion in the heat-affected zone (HAZ).

Strength vs. reliability trade-off: 316 is slightly stronger; 316L offers better weld integrity and cleanliness compliance (sanitary/CIP/SIP).

Selection rule of thumb:

Welded / sanitary / corrosive chloride environments: Prefer 316L.

Sustained high-temperature service or higher allowable stress: Consider 316/316H (or other high-temp grades).

Aggressive chlorides / stagnant seawater: Step up to duplex (2205/2507), 6Mo/904L, Ni-base or Ti as needed.

1) Chemistry & Metallurgy

| Element | 316 | 316L |

|---|---|---|

| C (Carbon) | ≤ 0.08% | ≤ 0.03% (low-C) |

| Cr | 16–18% | 16–18% |

| Ni | 10–14% | 10–14% |

| Mo | 2–3% | 2–3% |

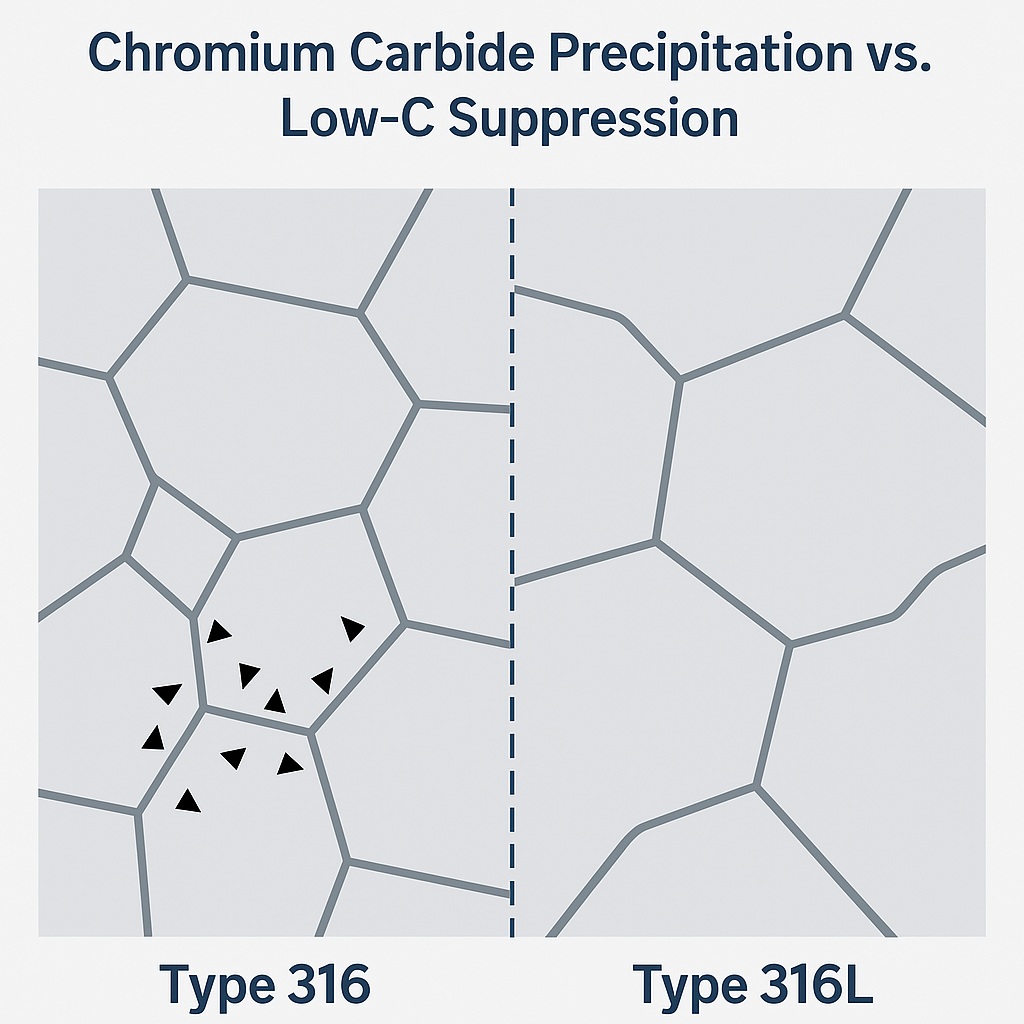

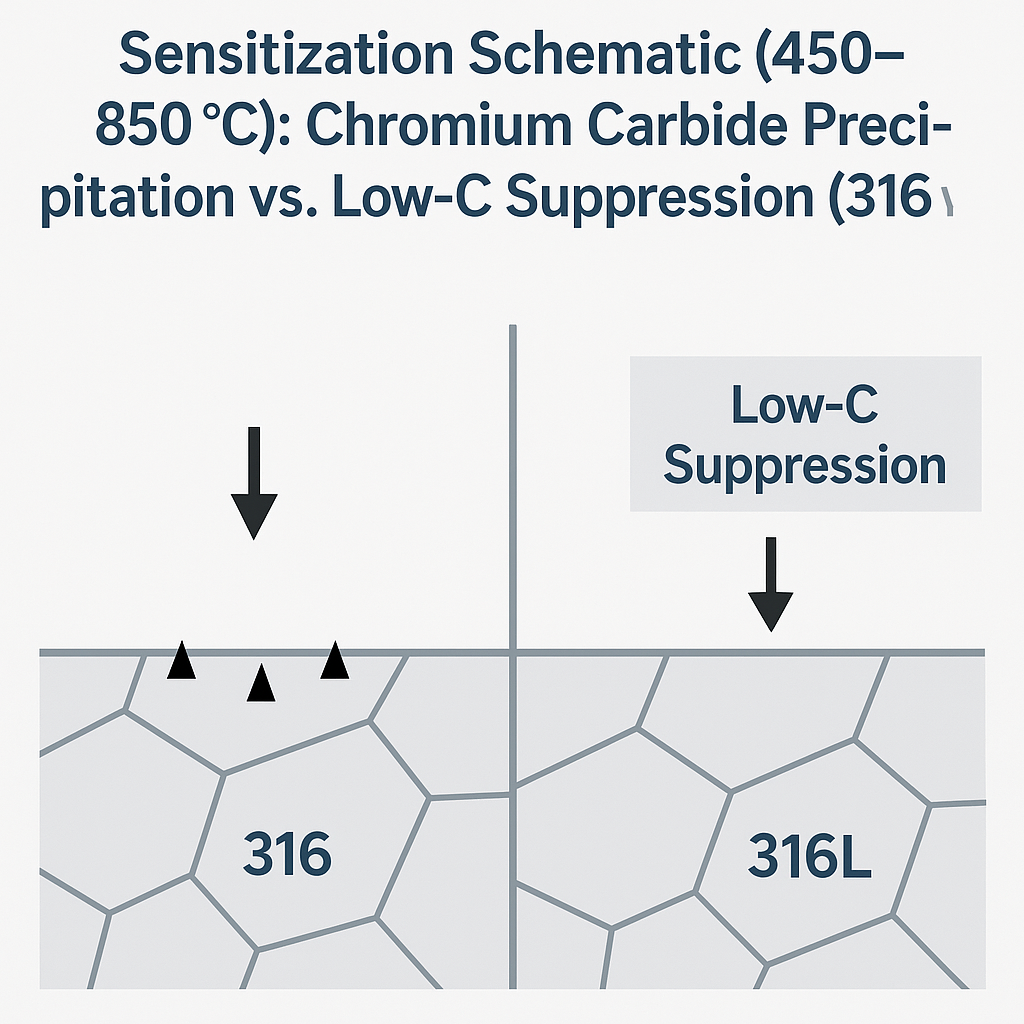

Why low-carbon matters: Lower C in 316L suppresses chromium carbide precipitation in the 450–850 °C range, limiting chromium depletion at grain boundaries. Result: lower sensitization risk and superior HAZ corrosion resistance after welding.

2) Mechanical Properties & Temperature Service

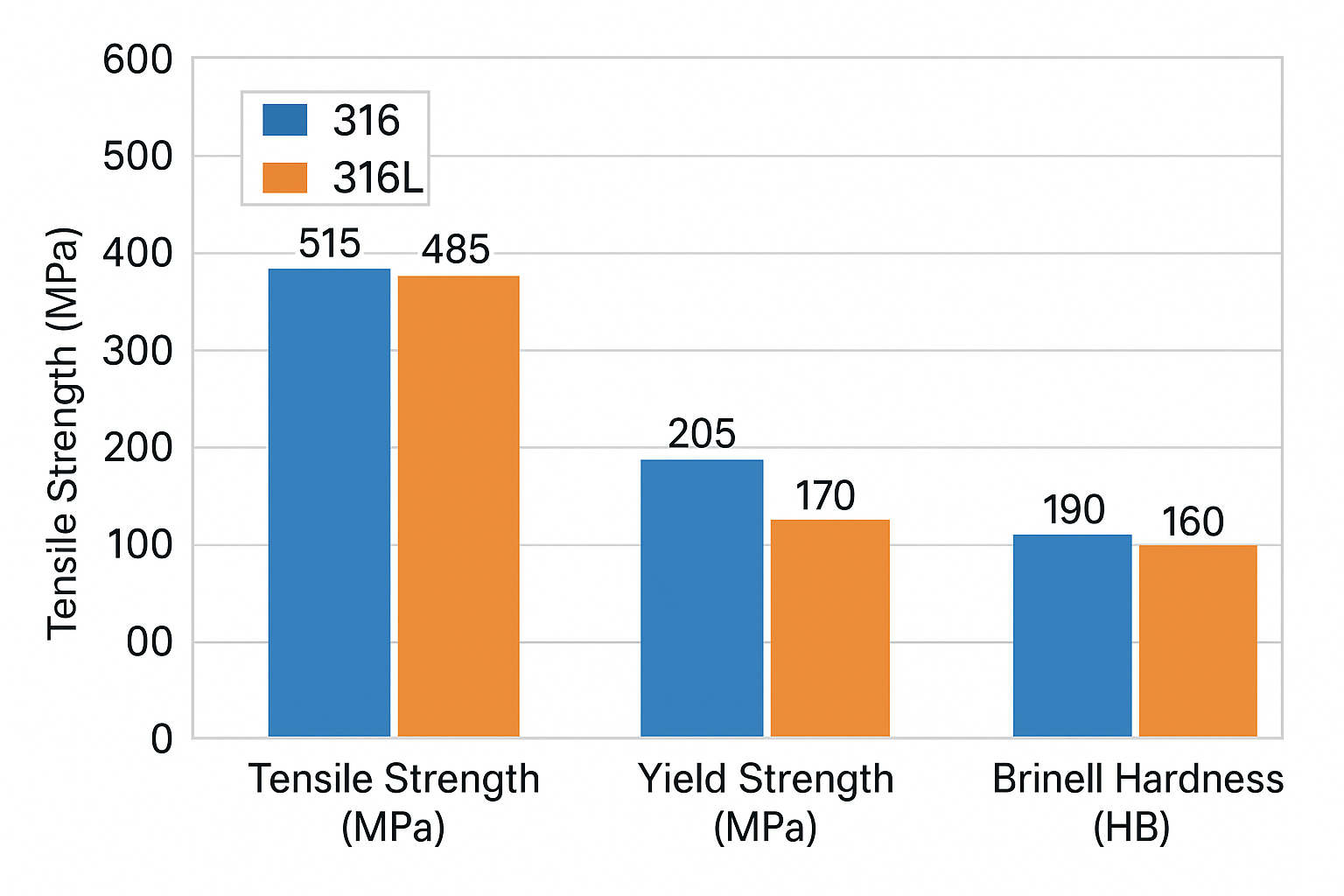

| Property (typical minimums) | 316 | 316L |

|---|---|---|

| Tensile strength | ≥ 515 MPa | ≥ 485 MPa |

| Yield strength | ≥ 205 MPa | ≥ 170 MPa |

| Elongation | ≥ 40% | ≥ 40% |

| Brinell hardness | ~150–200 HB | ~140–180 HB |

316 usually provides higher allowable stress.

316L has slightly lower strength but similar ductility; thickness/section can be adjusted to compensate in design.

Temperature guidance: for sustained high temp/creep consider 316/316H; for welded components with thermal cycling, 316L is generally preferred to avoid sensitization.

3) Corrosion Behavior in Practice

General corrosion / chlorides: 316 and 316L are both Mo-bearing austenitic grades superior to 304 in chloride resistance.

Welded zones: 316L maintains HAZ corrosion resistance closer to base metal due to low-C; 316 is more prone to HAZ intergranular corrosion after welding unless post-weld measures are taken.

Limitations: In stagnant seawater, high hypochlorite, or high crevice severity, pitting/crevice corrosion risk increases for both; consider duplex 2205/2507 or 6Mo/904L; for very aggressive media, consider C-276 or titanium.

4) Fabrication, Welding & Cleanliness

Weldability: Both are weldable; 316L is preferred to reduce sensitization and weld decay.

Forming & machining: 316L’s lower carbon can offer slightly easier forming; both machine similarly.

Sanitary/Clean service: For pharma/food (CIP/SIP), 316L with electropolish & passivation is the default; follow ASME BPE and cleaning protocols (e.g., ASTM A967/A380 for passivation/cleaning).

5) Instrumentation-Focused Selection Guide

Wetted parts (thermowells, sampling probes, pressure/level/flow wetted sections):

Mild-to-moderate chlorides / welded fabrication: 316L first choice.

High-chloride / hypochlorite / stagnant seawater / high crevice index: consider duplex or 6Mo/904L; Ni-base/Ti for extreme cases.

Tubing, manifolds, valves (3/5-valve manifolds, needle valves, fittings):

Coastal/outdoor chemical plants: 316L recommended; for severe crevice conditions, evaluate duplex/6Mo; control preload to limit crevice & SCC risk.

Housings & junction boxes:

Indoor dry: 304 acceptable.

Salt-spray/acid mist/coastal: 316L improves long-term cosmetics and sealing; add coatings or electropolish in erosive/UV conditions.

Sanitary/Hygienic:

Clamp ferrules & wetted lines: 316L + electropolish + passivation per ASME BPE.

High-temperature/thermal cycling:

Welded & cyclic mid-temp: 316L.

Long-term high temp strength-limited: 316/316H (or other high-temp alloys).

Cryogenic/low temperature:

316/316L retain good toughness; 316L helps keep weld-zone properties consistent.

Oxygen/high-purity/oxidizers:

Ensure degreasing/no-oil and surface cleanliness; baseline 316L, but move to Ni-base/Ti for strong oxidizers/halogenated media as needed.

6) Real-World References

Hong Kong-Zhuhai-Macao Bridge anchor systems: 316L widely used; 10-year service reports showed no weld-area corrosion in monitored zones.

Coastal power plant: 316 welded anchor bolts exhibited HAZ rusting within ~3 years, requiring rework—illustrating 316L’s advantage in welded coastal exposure.

7) Standards & Designations

UNS: 316L = S31603

ASTM: e.g., ASTM A276 (bars)

EN: 316L = 1.4404 (EN 10088-3)

JIS: SUS 316L

8) Procurement & QA Checklist

MTR verification: C ≤ 0.03% for 316L; Mo ≥ 2.0%; confirm solution anneal/heat treatment & microstructure.

Match product form & code: Plate/tube/forging ASTM/ASME/EN mapping and allowable stress differences.

Surface treatment: Passivate/clean to ASTM A967/A380; avoid cross-contamination and HAZ discoloration.

9) FAQ

Q1. Is 316L stronger than 316?

A: No. 316 usually has higher tensile/yield. 316L trades a little strength for welded corrosion reliability. Thickness upsizing can offset strength gaps in design.

Q2. Can I always substitute 316L for 316?

A: In most welded or hygienic services, yes. For sustained high-temperature applications where allowable stress governs, keep 316/316H on the table.

Q3. Which one for seawater?

A: Neither is ideal in stagnant or crevice-rich seawater. Consider duplex 2205/2507 or 6Mo/904L; escalate to Ni-base/Ti when required.

Q4. Are 316/316L magnetic?

A: In the annealed state both are essentially non-magnetic austenitic steels; cold work may introduce slight magnetism.

Q5. What about cost?

A: 316L can be marginally pricier, but lifecycle cost may be lower in welded/corrosive or sanitary duties due to reduced rework/failures.