The Graphene Powder Revolution—and Its Hidden Measurement Challenge

Graphene powder, composed of single-layer carbon atoms arranged in a hexagonal honeycomb structure, is transforming industries across the globe. Its exceptional strength, conductivity, and flexibility make it a vital material in everything from advanced electronics to energy storage and high-performance composites.

However, the handling of graphene powder presents a unique challenge.

Due to its ultra-fine particle size and low bulk density, even small measurement errors during storage or transfer can lead to material overflow, underfeeding, equipment clogging, or reduced process efficiency. In high-value manufacturing processes, such errors can quickly escalate into costly downtime or safety risks.

To overcome these challenges, manufacturers require highly sensitive and reliable level measurement solutions capable of operating flawlessly in dusty, low-density, and often high-temperature environments.

Why Conventional Sensors Fall Short

Traditional level measurement technologies often struggle with materials like graphene powder. The fine particles can cause bridging or ratholing in silos, generate static electricity, and adhere to sensor surfaces—all of which can skew or interrupt accurate readings.

These complications are further exacerbated in industrial environments where temperature extremes, vibration, or corrosive atmospheres are present.

That’s where Zero Instrument offers a breakthrough.

Zero Instrument Vibrating Rod Level Switch: Designed for Fine Powders

![Vibrating Rod Level Switch Image]

The Zero Instrument vibrating rod level switch is specially engineered for applications involving ultra-fine powders such as graphene. As the first dual-rod vibrating level switch developed domestically in China, it sets a new industry benchmark for precision and robustness.

Key Advantages:

High Sensitivity: The switch can detect powders with bulk densities as low as 0.02 g/cm³, thanks to precision resonance frequency tuning—ideal for materials like graphene.

High-Temperature Resistance: Operates in temperatures up to 250°C, and with optional water- or air-cooling systems, it can withstand up to 400°C.

Versatility: Effective in both solid level detection and interface detection between liquids and solids. Performs reliably in tall silos, narrow tanks, and environments with heavy vibration.

Anti-Adhesion Design: Its unique probe structure prevents material buildup, reducing maintenance needs and ensuring consistent operation even with sticky or clinging powders.

Durability & Diagnostics: Dual-rod construction enhances abrasion resistance and incorporates self-diagnostic features to pinpoint issues before they cause downtime.

Maintenance-Free Operation: Insensitive to changes in material characteristics, requiring little to no recalibration over time.

The probe is made from 316L and 318 S13 stainless steel, offering excellent corrosion resistance and long-term durability in aggressive industrial environments.

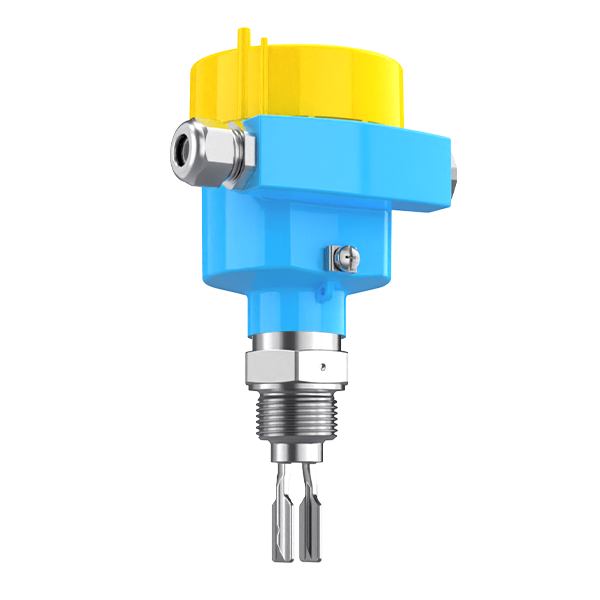

Zero Instrument Fork-11 Tuning Fork Level Switch: Precision Detection for Ultra-Light Powders

![Tuning Fork Level Switch Image]

The Fork-11 tuning fork level switch from Zero Instrument offers another ideal solution for measuring fine powders and flakes like graphene.

Operating based on vibration resonance, this switch detects the presence or absence of material through changes in oscillation frequency. Its performance is tailored for demanding powder handling scenarios.

Highlighted Features:

Ultra-Low Density Detection: Accurately senses materials with bulk densities as low as 0.008 g/cm³, making it well-suited for light, flaky substances.

Anti-Sticking Surface: Designed to repel powder buildup on the fork tines, ensuring stability and minimal maintenance.

Suspension Cable Option: Optional hanging probe design allows for use in tall or narrow silos—an excellent choice for light powder storage such as graphene silos.

High-Temperature Operation: Rated for up to 400°C, with consistent performance in extreme heat environments.

Self-Diagnostics: Built-in diagnostic tools enable precise fault detection, minimizing downtime and improving process reliability.

Corrosion-Resistant Construction: The wetted parts are made of 316L stainless steel, ensuring longevity even in highly corrosive atmospheres.

With its precision and adaptability, the Fork-11 is the smart choice for any manufacturer dealing with ultra-fine powders, especially in industries where product integrity and process uptime are paramount.

Conclusion: Reliable Level Measurement Is Key to Graphene Powder Success

As graphene powder continues to expand its role in cutting-edge applications, the need for accurate, stable, and maintenance-free level measurement becomes more urgent. Whether you’re producing advanced composites, conducting materials R&D, or operating a full-scale manufacturing facility, Zero Instrument’s level switches provide the confidence and precision you need.

Both the Vibrating Rod and Tuning Fork models are engineered for fine powder environments—offering unmatched sensitivity, temperature tolerance, and anti-adhesion performance.