📌 Background

In a 200,000-ton/year Linear Alkylbenzene (LAB) production unit, pressure transmitters located at the fractionation tower outlet were frequently failing due to severe corrosion. The process medium contained high-temperature, moist hydrofluoric acid (HF), which quickly attacked the Monel diaphragm of the pressure transmitters. On average, the transmitters lasted only 2–3 days before showing drifting measurements and alarming deviations.

This created a persistent operational headache—frequent replacements, high costs, and process instability.

⚠️ Failure Description

Due to process adjustments and throughput increases, a larger reflux rate led to insufficient fractionation. As a result, residual HF was carried into downstream instruments, including pressure transmitters. Though the process pressure remained within limits (as verified by mechanical gauges), the transmitters often reported over-range alarms due to membrane corrosion and drift.

🔍 Attempted Solutions

| Attempt | Method | Effectiveness |

|---|---|---|

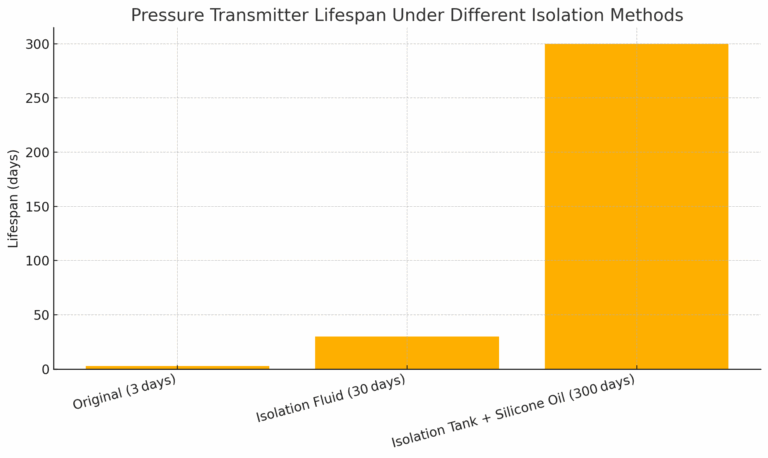

| 1️⃣ | Extended impulse tubing + heavy alkylbenzene as isolation fluid | Extended transmitter life to ~30 days, but corrosion still occurred eventually |

| 2️⃣ | Increased elevation of tapping point | Aimed to allow HF to drain naturally. Failed within 2–3 days again due to corrosion. |

| 3️⃣ ✅ | Installed isolation tank filled with methyl silicone oil | Achieved 300+ days of stable transmitter operation |

🛠️ Final Solution: Isolation Tank + Methyl Silicone Oil

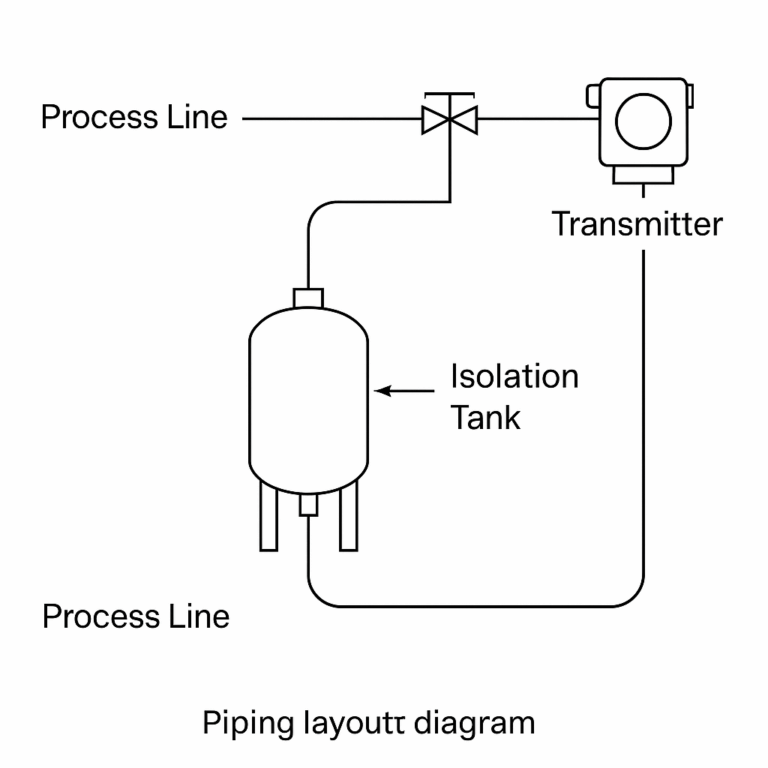

After repeated failures, an isolation tank was installed between the process and the pressure transmitter. This tank was filled with methyl silicone oil, chosen for its excellent chemical stability, thermal resistance, and hydrophobic nature.

✅ Result: The transmitter operated normally for over 300 days without failure, with stable and accurate pressure readings.

⚙️ Additional Improvements

While the corrosion problem was resolved, HF buildup occasionally caused blockages at the pressure tapping point. To address this:

A larger-bore tapping valve was used.

A backup pressure tapping valve was installed on the same pipe for emergency switchover.

🧾 Technical Highlights

| Item | Description |

|---|---|

| Corrosive Agent | Hydrofluoric Acid (HF), moist, high-temperature |

| Original Transmitter Diaphragm | Monel |

| Isolation Fluid | Methyl Silicone Oil |

| Isolation Method | External isolation tank filled with oil |

| Resulting Life Extension | From 3 days → 300+ days |

| Additional Measures | Tapping valve upgrade + backup port |

📘 Glossary

Methyl Silicone Oil: A silicone-based fluid with high thermal and chemical resistance. Ideal for harsh environments.

Isolation Tank: A sealed intermediate vessel used to isolate corrosive media from sensitive instrumentation.

✅ Conclusion

This case highlights how custom isolation design combined with proper fluid selection can significantly extend transmitter life and ensure operational stability in highly corrosive environments such as HF-containing processes.

For similar challenges involving corrosive acids, consider isolation tanks and high-grade barrier fluids as a practical and cost-effective solution.