Valves are essential components in pipeline systems across many process industries. Among the most critical aspects of valve performance is the sealing mechanism, as poor sealing can lead to serious safety hazards. Incidents caused by valve leakage, particularly in confined spaces, have led to suffocation, poisoning, fires, and explosions.

Note: No matter how reliable a valve is, relying on a single valve for sealing in confined spaces is unsafe and not recommended.

This article focuses on the two major types of valve sealing structures: soft seals and hard seals, comparing their working principles, applications, and advantages/disadvantages.

1. What Is a Soft Seal Valve?

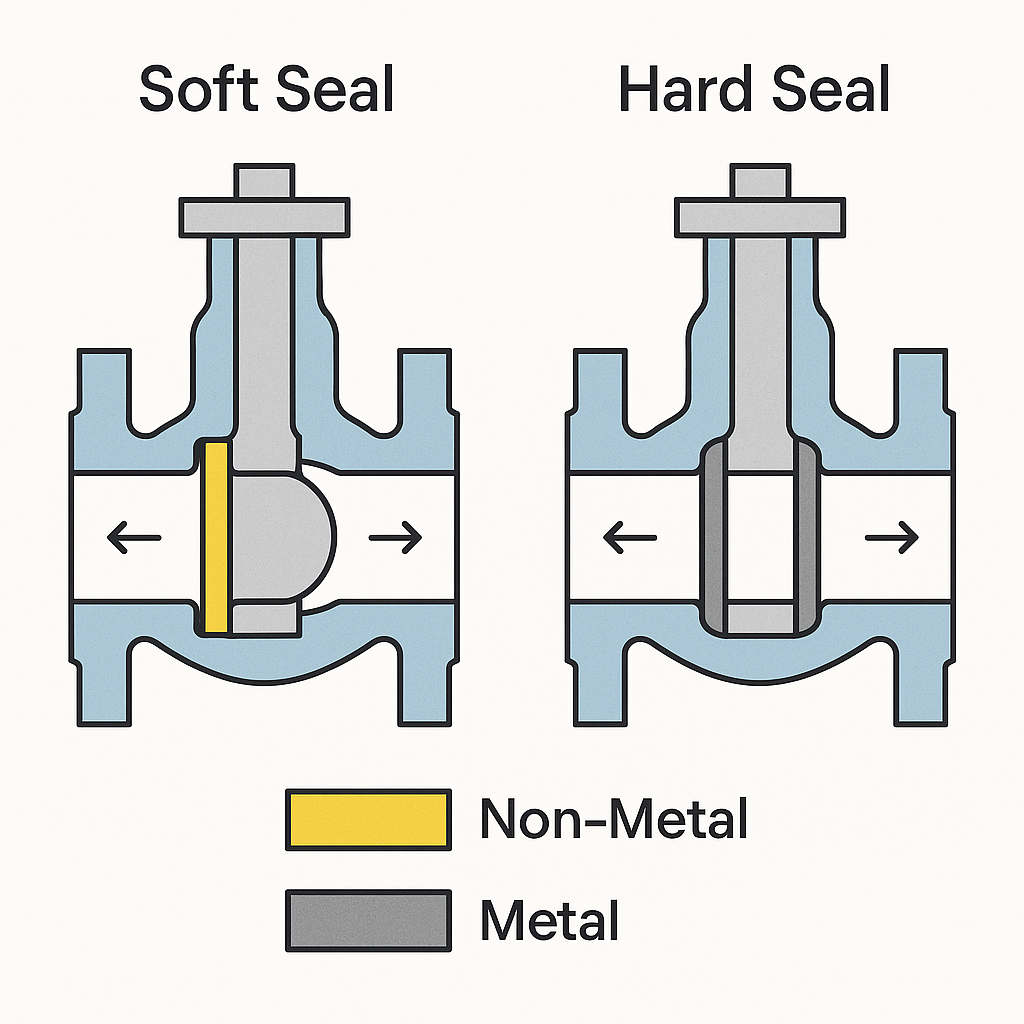

A soft seal valve uses a sealing pair composed of one metallic surface and one non-metallic material, such as PTFE (Teflon). The non-metallic side provides good elasticity and deformability, allowing it to achieve tight shutoff even with relatively rough machining surfaces.

2. What Is a Hard Seal Valve?

A hard seal valve uses a metal-to-metal contact for sealing. Since both sides of the sealing surface are metallic, they have low elasticity and require high-precision machining to achieve proper fit and sealing performance.

3. Comparative Table: Soft Seal vs. Hard Seal

| Feature | Soft Seal Valve | Hard Seal Valve |

|---|---|---|

| Sealing Material | Metal + Non-metal (e.g. PTFE) | Metal + Metal |

| Sealing Tightness | Excellent at low/medium pressure | Good, depends on precision |

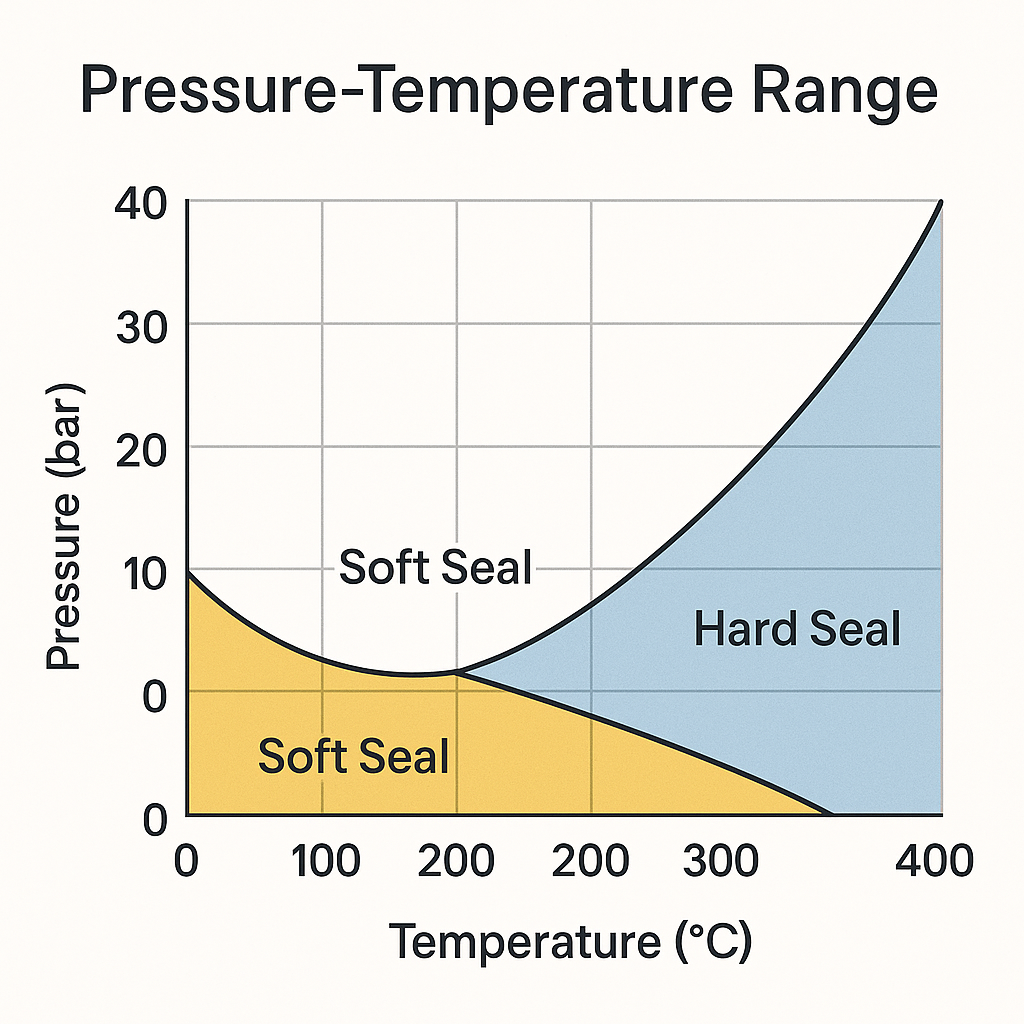

| Pressure Range | Suitable for low-pressure systems | Suitable for high-pressure systems |

| Temperature Range | Limited (generally <200°C) | High (can handle >400°C) |

| Elastic Compensation | High due to soft material | Low, requires precise fit |

| Manufacturing Cost | Lower | Higher |

| Maintenance | Easier to replace soft parts | Requires expertise and machining |

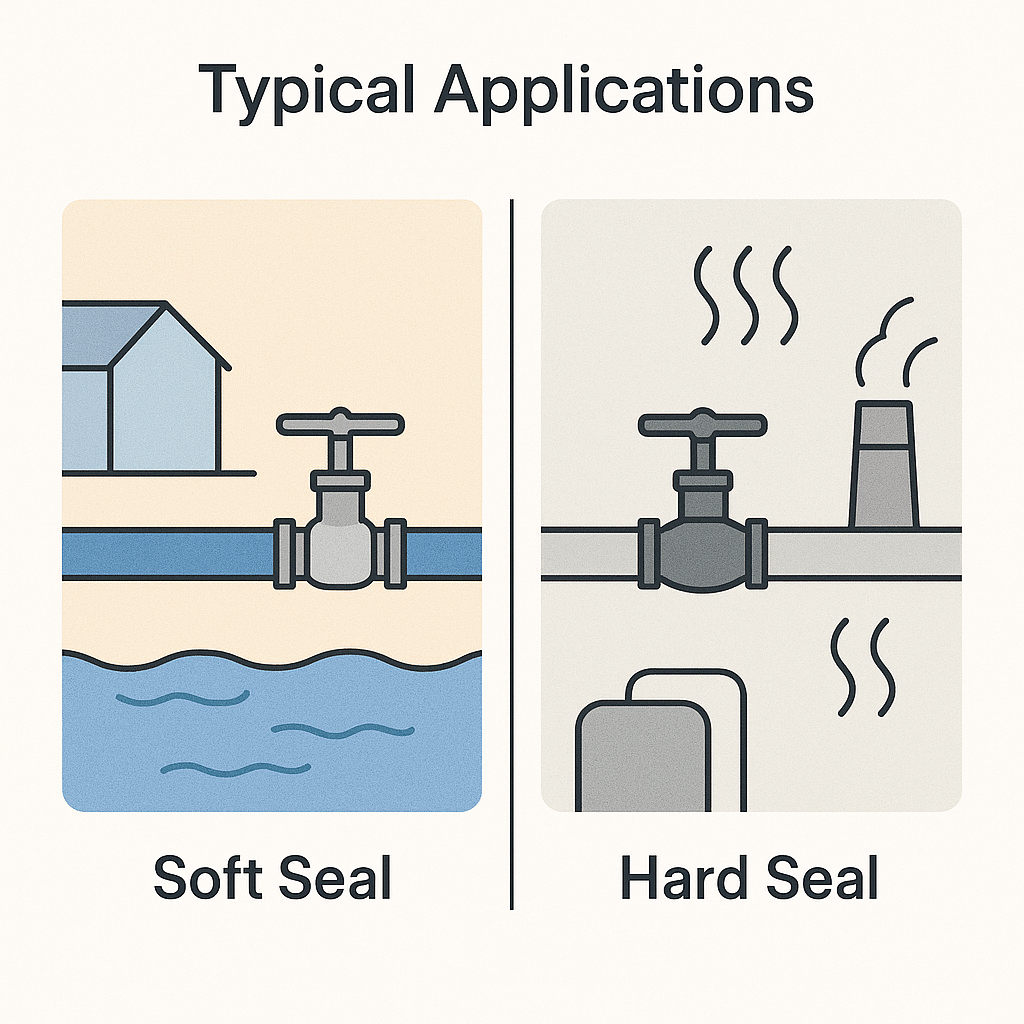

| Application | Water, HVAC, food, general industry | Steam, power, chemical processing |

4. Application Considerations

When to Use Soft Seal Valves:

Low-pressure, ambient temperature conditions

Where frequent operation and maintenance is needed

Systems involving clean or non-corrosive fluids

Cost-sensitive applications

When to Use Hard Seal Valves:

High-temperature and high-pressure environments

Steam, superheated water, and abrasive or corrosive fluids

Where long-term durability and tight shutoff are critical

Situations demanding high sealing integrity (e.g. safety systems)

5. Summary

There is no one-size-fits-all answer to whether a soft seal or hard seal valve is better. The right choice depends on the specific operating conditions:

Soft seals provide excellent sealing in less demanding environments and are more cost-effective.

Hard seals are essential for harsh conditions where temperature, pressure, and chemical resistance are critical.

Understanding the strengths and limitations of each type ensures safer and more reliable valve selection.