Introduction

When selecting, using, or maintaining an industrial instrument, it is essential to understand the quality indicators that define its performance. The six most common indicators are:

Accuracy

Hysteresis (Backlash/Variation)

Sensitivity

Dead Zone

Stability

Response Time

These parameters are the foundation for evaluating whether an instrument meets the requirements of industrial processes.

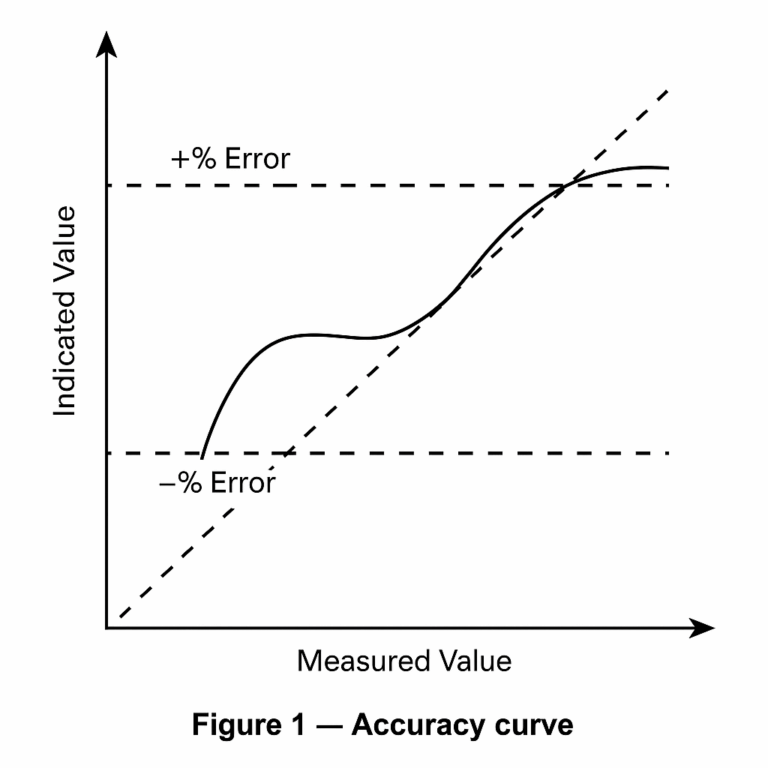

1. Accuracy

Accuracy refers to the degree of agreement between the instrument’s indication and the true (or agreed) value of the measured variable. It is influenced by systematic error, random error, hysteresis, and dead zone.

The accuracy is usually expressed as a percentage of the reference error:

δc=Amax−AminΔc×100%

Where:

Δc: absolute measurement error

Amax: upper range value

Amin: lower range value

Example

A temperature indicator with a range of 0–800 °C and an accuracy grade of 0.5 must not exceed ±4 °C error under specified conditions.

Table 1 — Typical Accuracy Grades

| Grade | Max Allowable Error (%) |

|---|---|

| 0.1 | ±0.1% |

| 0.5 | ±0.5% |

| 1.0 | ±1.0% |

| 2.5 | ±2.5% |

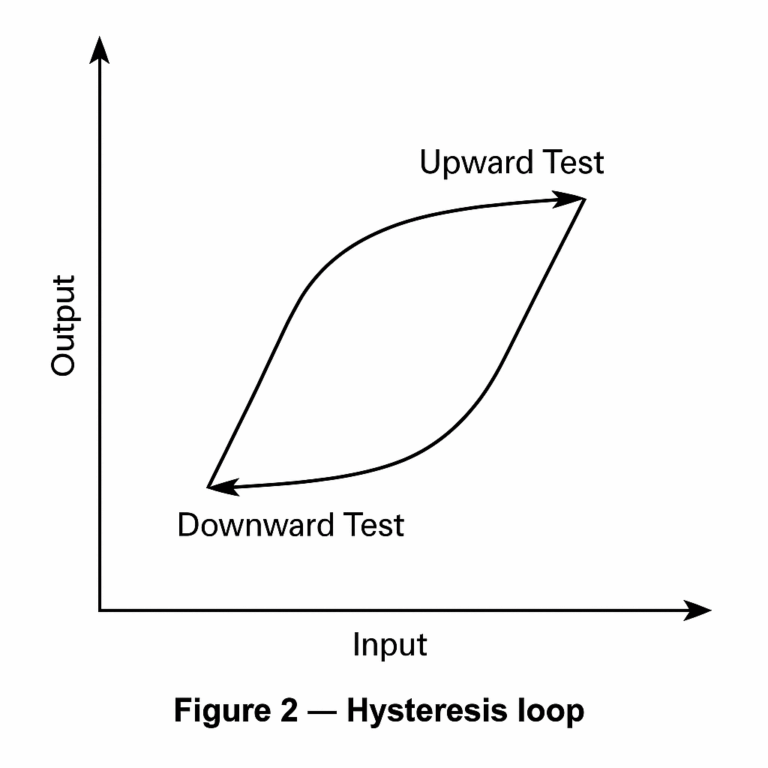

2. Hysteresis (Variation)

Hysteresis describes the difference between forward and reverse readings when measuring the same parameter under identical conditions.

δb=Amax−AminΔb×100%

Where:

Δb: maximum difference between up-scale and down-scale readings.

In practice, hysteresis should not exceed the allowable error. It is checked during instrument calibration by performing both upward and downward tests.

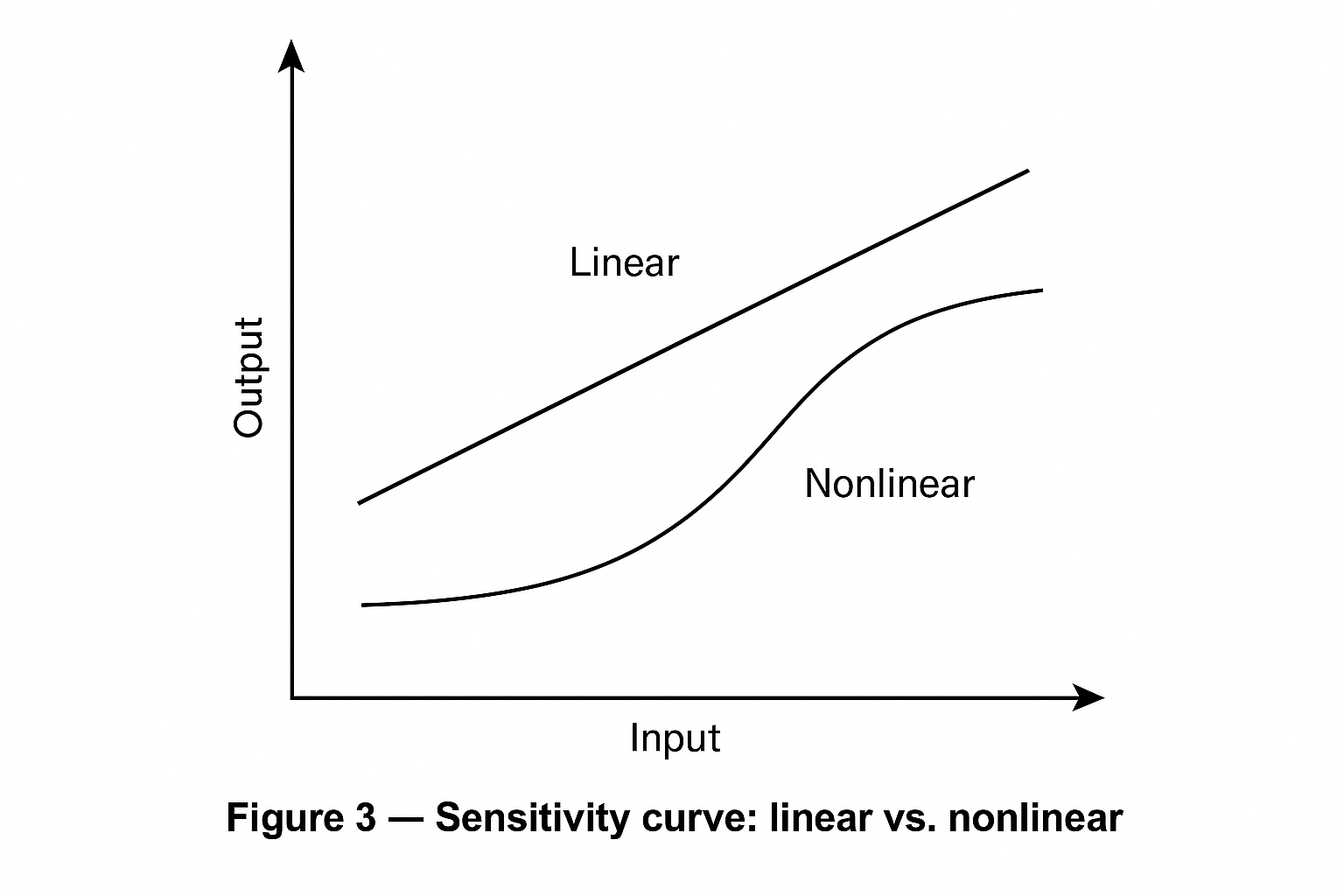

3. Sensitivity

Sensitivity is the ratio of output signal change to the corresponding input change:

S=ΔAΔα

Where:

Δα: change in output (e.g., pointer displacement or electrical signal)

ΔA: change in input signal

If sensitivity is uniform across all scales, the instrument exhibits a linear response; otherwise, it is nonlinear.

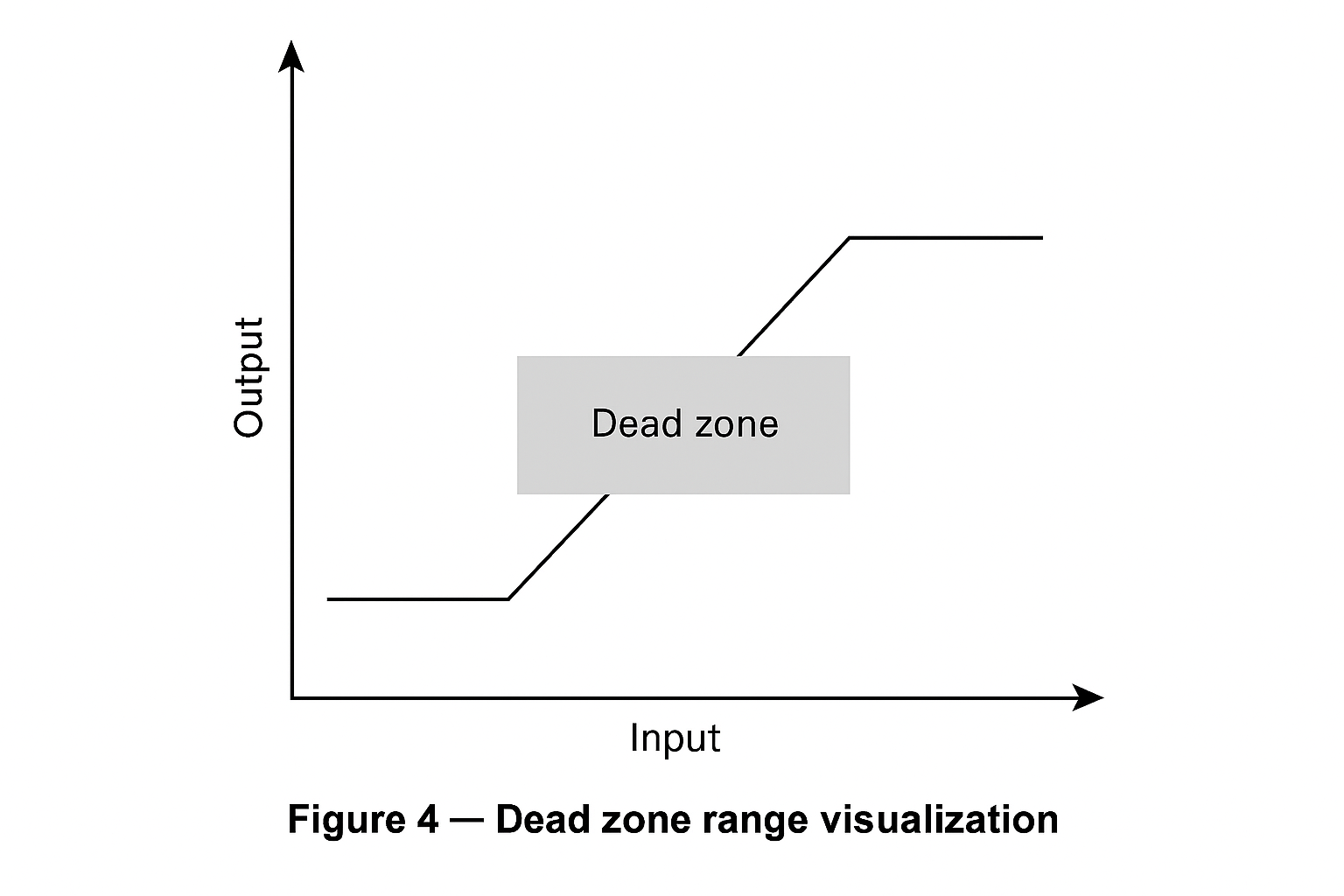

4. Dead Zone

The dead zone is the maximum range of input signal change that does not produce an output response.

Example: A temperature indicator stabilizes at 120 °C.

Output increases only when temperature rises to 120.1 °C.

Output decreases only when temperature drops to 119.9 °C.

Thus, the dead zone = 0.2 °C.

Note: Sometimes referred to as the resolution limit, it must not exceed half the allowable error.

5. Stability

Stability refers to the instrument’s ability to maintain consistent readings over time and under varying conditions.

Time stability: expressed as the random variation of indication within a time interval.

Environmental stability: expressed as influence error (e.g., temperature coefficient: deviation per 1 °C).

A stable instrument ensures reliable performance in long-term applications.

6. Response Time

Due to inertia, an instrument does not immediately reflect the changes in a process variable. Response time is the delay between the input change and the correct output display.

Short response time → suitable for fast-changing processes.

Long response time → only suitable for stable processes.

Conclusion

The six quality indicators — accuracy, hysteresis, sensitivity, dead zone, stability, and response time — are critical for evaluating and selecting industrial instruments. An ideal instrument should achieve an optimal balance of these parameters, ensuring high precision, reliability, and suitability for its intended application.