Magnetic level gauges have become essential instruments for accurate and reliable liquid level measurement across various industries. Among them, side-mounted magnetic level gauges offer numerous advantages, including high precision, durability, and adaptability to different industrial applications. This article explores the core features and benefits of side-mounted magnetic level gauges.

1. High-Precision Measurement with Clear Visual Display

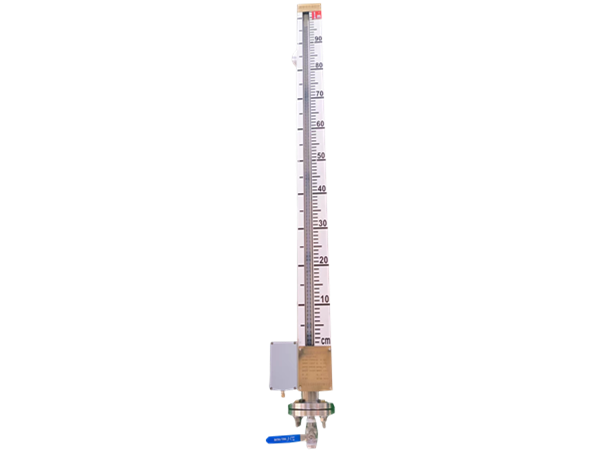

The side-mounted magnetic level gauge employs magnetic sensor technology, utilizing the magnetic coupling between the float and the indicator columns to ensure real-time liquid level monitoring. The measurement error is controlled within ±10mm, providing highly accurate readings.

The display panel features bicolor rotating flaps that change color as the liquid level fluctuates, offering a clear and intuitive visual indication. The design ensures a full-range display without blind zones, making it ideal for applications with significant liquid level variations, such as large storage tanks and reaction vessels.

2. Corrosion Resistance and Compatibility with Various Media

To withstand harsh industrial conditions, side-mounted magnetic level gauges are constructed using high-quality materials such as stainless steel, PVC, or 316+PTFE/FEP coatings. These materials provide exceptional resistance against strong acids, alkalis, high temperatures (up to 450°C), and high pressures (up to 25MPa), significantly reducing the risk of leakage due to corrosion.

Unlike traditional float-type level gauges, the magnetic level gauge is not affected by liquid viscosity or density variations, making it highly suitable for a wide range of liquids, including oils, chemicals, and viscous slurries.

3. Space-Saving Design and Easy Installation

The side-mounted design allows for direct integration into the side of a container, requiring only a small opening in the tank for installation. This feature minimizes space consumption, making it ideal for industrial environments where equipment space is limited.

Additionally, the simple mechanical structure of the gauge ensures quick installation and easy maintenance. The float chamber can be detached independently, allowing for convenient cleaning or replacement without interrupting the entire system. The gauge can be connected via flange or threaded interfaces, eliminating the need for complex calibration or electronic adjustments.

4. Multi-Parameter Integration and Remote Monitoring Capabilities

Modern industrial processes demand automated and real-time monitoring. The side-mounted magnetic level gauge can be integrated with remote transmitters, supporting output signals such as 4-20mA, HART, or dry reed switches, enabling seamless liquid level data transmission to DCS/PLC control systems.

For enhanced safety and efficiency, it supports automatic high/low-level alarms and interlock control systems. Additionally, it is compatible with the RS485 communication protocol, making it suitable for industrial IoT applications where centralized monitoring is required.

5. High Safety Standards and Explosion-Proof Design

With its fully enclosed structure, the side-mounted magnetic level gauge effectively isolates the measuring medium from the indicator, ensuring zero leakage and high durability. This feature is particularly valuable in hazardous environments, such as petroleum storage tanks and chemical processing plants.

Certified with Ex d IIC T6 explosion-proof ratings, it meets stringent safety requirements for flammable and explosive areas. Additionally, its mechanical, non-electronic operation provides superior shock and vibration resistance, allowing stable performance even under high-pressure or turbulent conditions.

6. Wide Range of Industrial Applications

The side-mounted magnetic level gauge is widely used in various industries due to its versatile functionality and robust construction. Typical applications include:

Petrochemical industry: Monitoring liquid levels in oil storage tanks and chemical reactors.

Power plants: Measuring boiler water levels to ensure efficient steam generation.

Environmental protection: Used in wastewater treatment plants for continuous liquid level monitoring.

Food and pharmaceutical industries: Ideal for sterile storage tanks, ensuring safe handling of sensitive liquids.

Extreme temperature and pressure conditions: Performs reliably in high-temperature steam and low-temperature liquefied gases applications.

Conclusion

The side-mounted magnetic level gauge is a highly reliable, durable, and precise instrument designed to meet the rigorous demands of various industrial sectors. With superior corrosion resistance, easy installation, automation capabilities, and high safety standards, it proves to be an indispensable choice for liquid level measurement in complex and critical applications.

For industries requiring accurate, maintenance-friendly, and explosion-proof level measurement solutions, the side-mounted magnetic level gauge remains a top-tier option for ensuring operational efficiency and safety.