In fire safety design reviews for construction projects, even though the fuel storage room in a diesel generator room may not be large, it often faces scrutiny. Experienced designers often encounter a situation where an expert casually reviews the design and says, “Hey, no flammable gas detectors here?” followed by, “This poses a major safety risk!” This leaves the construction team uncertain about whether to install the detectors — it may seem redundant, but leaving them out could also be seen as non-compliant.

1. Is the “Diesel Fuel Storage Room” Misjudged?

From a review perspective, the expert’s intent is correct: safety first. However, many people mistakenly apply standards meant for the petrochemical industry, overlooking differences in applicability.

The most frequently referenced standard is the “Design Standard for Combustible and Toxic Gas Detection and Alarm Systems in Petrochemical Industries” (GB/T50493 – 2019). This standard is well-written, clear in its definitions, and comprehensive in its tables, making it almost the “bible” for gas detection design. However, it is important to note the first chapter’s second article:

“This standard applies to the design of combustible and toxic gas detection and alarm systems in new and expanded petrochemical projects.”

This means it is a recommended standard for the petrochemical industry, not a mandatory requirement for other industries.

2. Is Diesel Vapour Considered a “Flammable Gas”?

According to the GB/T50493 – 2019 standard, flammable gases are defined as gases or vapors formed by Class A combustible liquids (gasified) or certain classes of flammable gases:

Diesel, in its normal state, is a liquid and is not considered a Class A gas. The key indicator in evaluating the fire hazard of a liquid is its flash point.

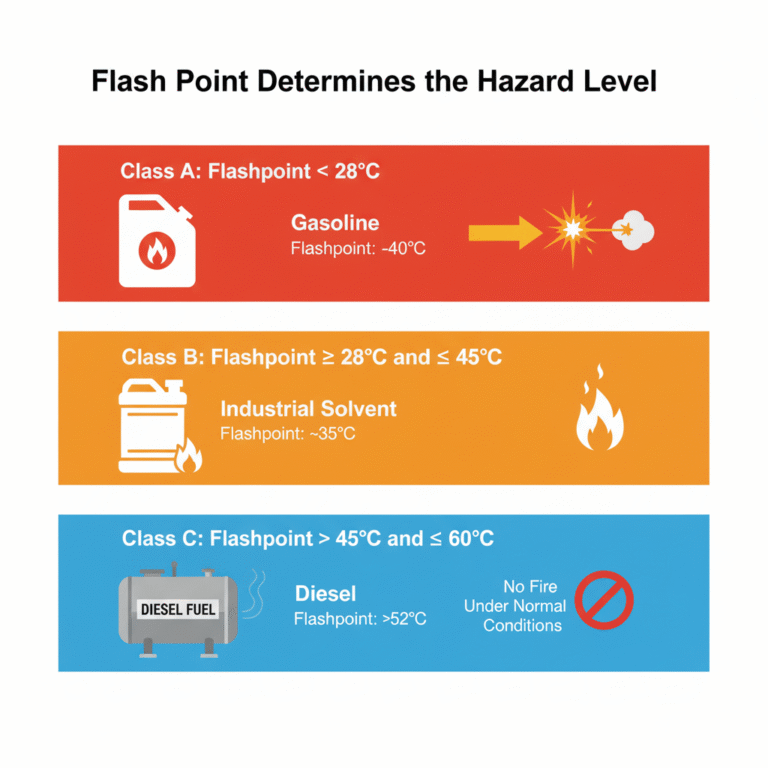

3. Flash Point Determines the Hazard Level

According to the “Fire Prevention Design Standard for Petrochemical Enterprises” (GB50160 – 2008 (2018)):

Class A: Flashpoint < 28°C

Class B: Flashpoint ≥ 28°C and ≤ 45°C

Class C: Flashpoint > 45°C and ≤ 60°C

For automotive diesel, the flashpoint is generally greater than 45°C, often exceeding 60°C, which places it in Class B. Since Class B liquids have lower vapor concentrations, weaker diffusion, and higher ignition points, they rarely form explosive gas mixtures under normal conditions. Only in cases of high-temperature leakage, poor ventilation, or specific confined environments could they pose a risk.

4. Why Do Some Insist on Installing Detectors?

There are both psychological and institutional factors at play here.

Psychological Factors:

During safety reviews, experts often think in terms of the worst-case scenario: “What if there’s a leak? What if the temperature rises?” As a result, installing a flammable gas detector seems like a safer choice.

Institutional Factors:

There is a lack of independent “fuel storage room detection standards” in non-petrochemical industries, so design teams often default to the petrochemical standards, even though they don’t technically apply. However, borrowing from another sector does not mean it’s mandatory.

For building projects, the following standards should be prioritized:

Building Fire Prevention Code GB50016-2014 (2018)

Diesel Generator Room Design Code (local standards)

Building Electrical Engineering Design Standards GB51348-2019

None of these standards explicitly require the installation of flammable gas detection systems in diesel fuel storage rooms.

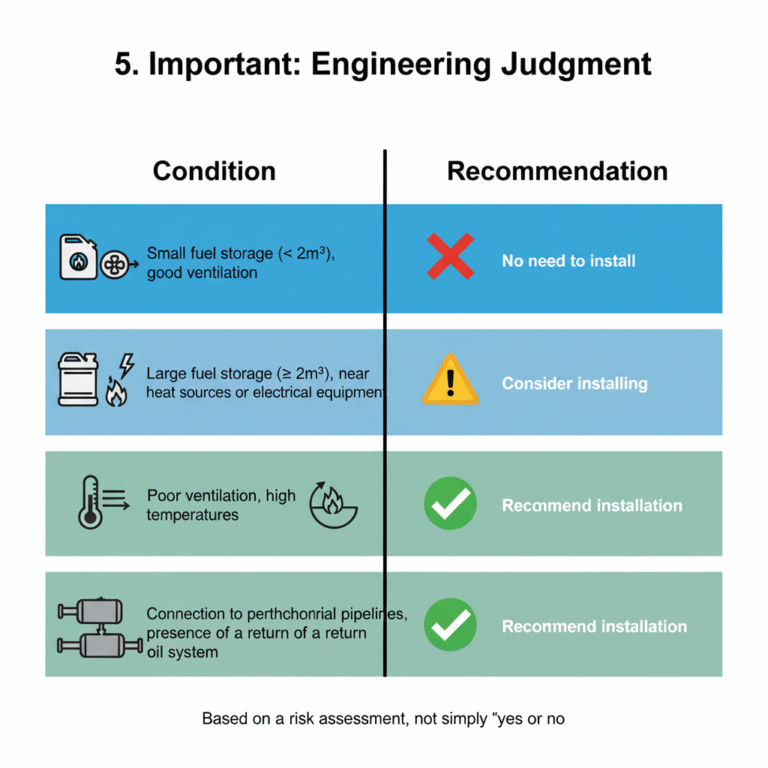

5. Important: Engineering Judgment

Safety design is not about “copy-pasting” regulations, but rather about risk-based decision-making. For a diesel fuel storage room, consider these conditions to determine whether a gas detector is needed:

| Condition | Recommendation |

|---|---|

| Small fuel storage (<2m³), good ventilation | ❌ No need to install |

| Large fuel storage (≥2m³), near heat sources or electrical equipment | ⚠️ Consider installing |

| Poor ventilation, high temperatures | ✅ Recommend installation |

| Connection to petrochemical pipelines, presence of a return oil system | ✅ Recommend installation |

This is not a simple “yes or no” question; it should be based on an assessment of the actual risk level.

6. Common Misconceptions

🚫 Misconception 1: Diesel gas is as dangerous as gasoline

Gasoline has a flashpoint of about -40°C, making it explosive even at room temperature. In contrast, diesel’s flashpoint exceeds 45°C, and it evaporates very slowly, making the risk far lower under normal conditions.

🚫 Misconception 2: Oil odor equals flammable gas

Oil odors mostly come from heavier hydrocarbons, which are not explosive gases. Gas detectors may not respond properly to these odors and may trigger false alarms.

🚫 Misconception 3: Any standard mentioning “gas” must be followed

It’s important to understand the scope of applicability. GB/T50493 is a recommended standard for the petrochemical industry and is not a mandatory building regulation.

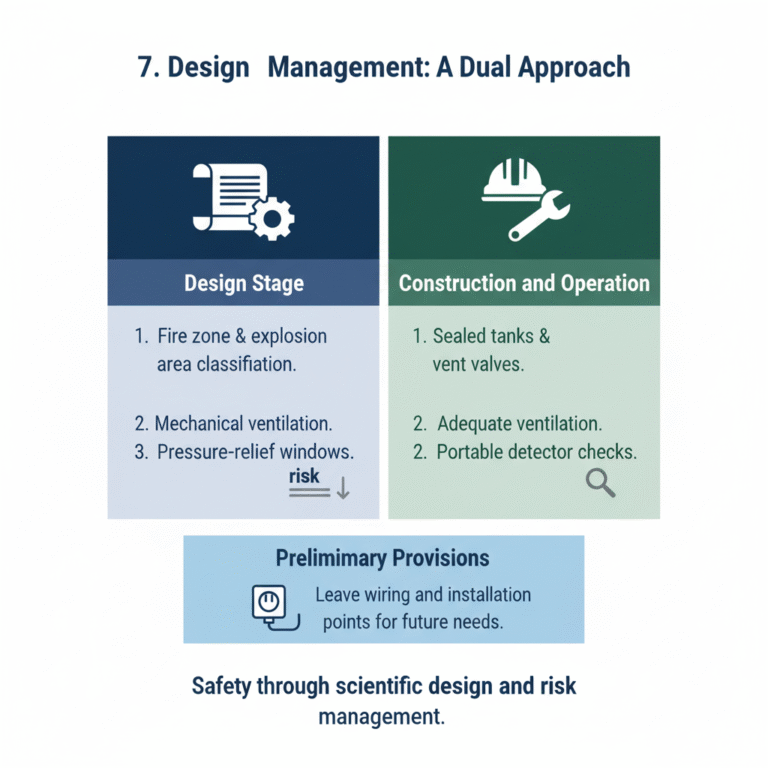

7. Design and Management: A Dual Approach

A sensible approach includes:

Design Stage:

Determine whether a combustible gas environment exists based on fire zone and explosion area classifications. If no explosion risk is found, mechanical ventilation and pressure-relief windows can be used to reduce risk.

Construction and Operation:

Ensure tanks are properly sealed, vent valves work correctly, and ventilation is adequate. Periodically check oil and gas concentrations with portable detectors.

Preliminary Provisions:

Even if detectors are not installed immediately, leave provisions for wiring and installation points, allowing quick installation if risk levels rise in the future.

8. Conclusion

The diesel fuel storage room in a diesel generator room is a typical “gray area” in safety design: the risk is low, but it receives high attention. From a regulatory standpoint, there is no mandatory requirement for flammable gas detectors. However, from a safety management perspective, their installation can be beneficial under high-risk conditions. Designers should provide evidence-based risk assessments, while experts should review the design based on both standards and factual information. Owners should view “extra safety features” beyond the standards with a rational mindset. Safety should not rely on “installing more equipment” but should be grounded in scientific design and risk management.