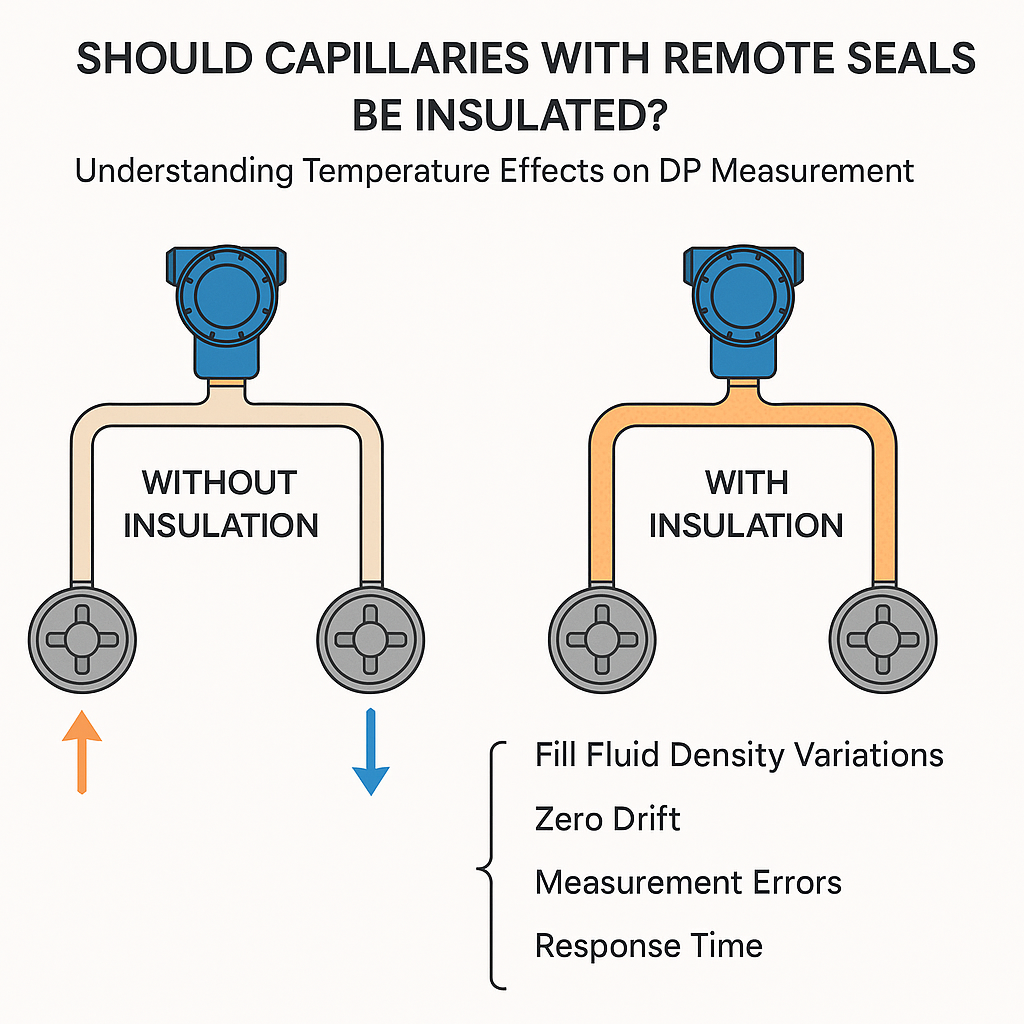

Are you experiencing erratic readings, unexpected zero drift, or sluggish response in your differential pressure transmitters with remote diaphragm seals? These issues often occur when large ambient temperature variations affect the capillaries and their fill fluid. In low temperatures, the fill fluid may thicken or even solidify; in high temperatures, expansion slows down response times and introduces measurement errors.

So, should you insulate the capillaries? How exactly does temperature impact your measurement accuracy? Let’s break it down.

Do Capillary Systems Require Insulation?

1. Generally, Insulation Is Not Required

In normal environments, the fill fluid inside the capillaries (commonly silicone oil) is designed to tolerate typical temperature fluctuations without additional insulation.

2. Insulation in Cold Regions or Low Temperatures

In extremely cold climates or when ambient temperatures drop below the freezing point of the fill fluid, the fluid can thicken or even solidify, degrading the transmitter’s accuracy. In such cases, insulation (or even electrical tracing) is required to keep the fluid within its optimal viscosity range.

3. Special Cases Requiring Insulation

Insulation is also recommended if:

The capillaries are installed outdoors and exposed to direct sunlight, heaters, or cooling sources.

The system operates in environments with extreme temperature fluctuations (day/night temperature swings).

4. Avoid Overheating

While heat tracing or insulation may be necessary in some cases, excessive heat can cause the fill fluid to expand excessively or vaporize, which may damage the transmitter. Controlled heating systems with thermostats are preferred.

How Temperature Affects Capillary Performance

1. Fill Fluid Density Variations

Fill fluid (e.g., silicone oil) expands as temperature rises and contracts as it falls. This thermal expansion and contraction alters the static pressure within the capillaries, introducing measurement inaccuracies.

Example: During day-night cycles in winter, thermal expansion and contraction of the fill fluid can lead to fluctuating forces on the sensing diaphragm, resulting in significant measurement errors.

2. Zero Drift

Even when the capillaries are of equal length, temperature-induced changes in the fill fluid’s density create differential static pressure. This phenomenon causes zero drift in the transmitter.

Example: In a DN80 differential pressure transmitter, an ambient temperature change from 25°C to 45°C can lead to a zero drift of approximately 280 Pa.

3. Measurement Errors

Besides density changes, thermal gradients along the capillaries can cause unequal pressure transmission. In high-temperature environments, the capillary section near the process vessel expands more than the remote section, leading to unstable or inaccurate level measurements.

4. Response Time

Capillaries with smaller diameters introduce greater resistance to pressure transmission, and longer capillaries further increase response time. At high temperatures, accelerated fill fluid expansion can also slow down the pressure signal propagation.

Recommendations

✅ For standard environments, insulation is unnecessary.

✅ For cold climates (< fill fluid freezing point), use insulation or heat tracing.

✅ For high-temperature environments, ensure controlled insulation to avoid vaporization of fill fluid.

✅ Always check the fill fluid’s temperature limits and the manufacturer’s specifications.