How Radar and Ultrasonic Level Sensors Improve Ship Stability, Compliance, and Fuel Efficiency

1. Importance of Draft Measurement

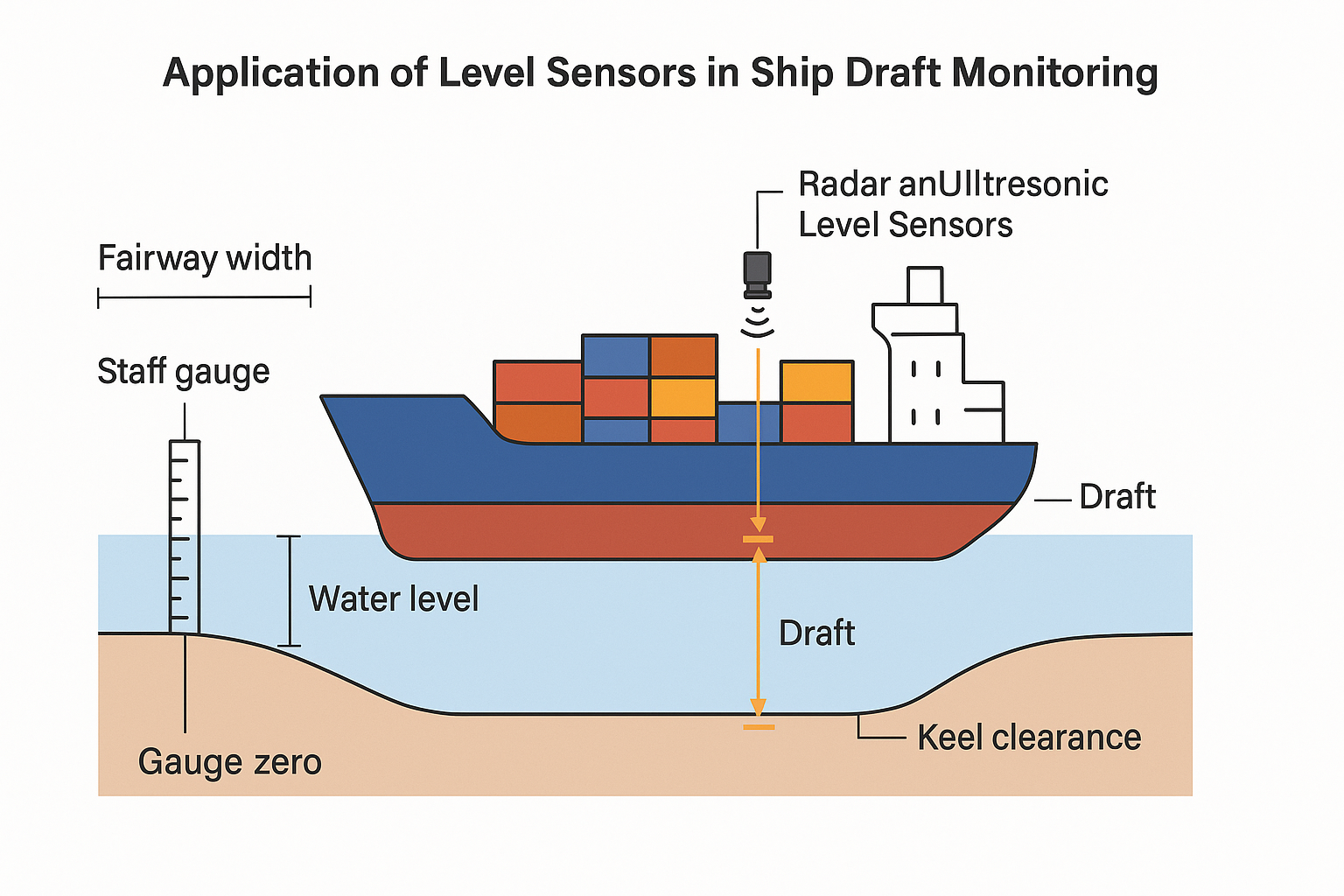

Draft—the vertical distance from the waterline to the lowest point of a vessel’s hull—is one of the most critical parameters in maritime operations. Accurate draft measurement plays a vital role in ensuring safe navigation, reducing the risk of grounding, optimizing fuel consumption, and maintaining cargo safety.

Reliable draft data enables ship operators to:

Confirm vessel loading limits

Optimize trim and ballast water levels

Enhance voyage planning and route selection

Ensure regulatory compliance with IMO and port authorities

Modern level measurement technologies, particularly radar and ultrasonic level sensors, have become essential tools in providing continuous, precise, and reliable draft data—especially under challenging marine conditions.

2. Operational Impacts of Draft on Ship Performance

Ship draft affects a range of operational and safety parameters, including:

● Fuel Efficiency

Proper trim and even weight distribution—guided by draft data—help minimize drag and reduce fuel consumption.

● Cargo Safety

Maintaining draft within safe operating limits reduces structural stress on the hull and protects cargo integrity.

● Navigational Safety

Real-time draft readings help prevent grounding in shallow waters and enhance maneuverability, especially in narrow channels, ports, or congested shipping lanes.

● Stability and Trim Control

Draft measurements from multiple points (bow, stern, port, and starboard) allow dynamic ballast adjustments to ensure optimal vessel stability.

3. Sensor Technologies for Draft Measurement

Two types of non-contact level sensors are widely adopted for draft and ballast water measurement:

3.1 Radar Level Sensors

Radar-based level sensors are especially suitable for enclosed ballast tanks or draft measurement pipelines. Their key features include:

✅ Adaptive Technology

Advanced radar units come with self-adaptive algorithms that automatically adjust signal processing to match changing sea states, cargo loads, and tank conditions.

✅ Non-Contact Measurement

Radar sensors operate without physical contact with liquids, minimizing maintenance and ensuring long service life in corrosive or contaminated environments.

✅ Wide Measuring Range

Premium radar models can measure ranges up to 120 meters, making them ideal for large vessels and deep draft monitoring.

✅ Corrosion Resistance

Constructed from marine-grade materials, these sensors withstand saltwater exposure and harsh weather conditions.

✅ Bluetooth Connectivity

Modern radar systems support wireless monitoring through mobile apps, enabling remote diagnostics, configuration, and real-time data visualization.

✅ Robust Performance

Radar level sensors function reliably under extreme temperature and pressure variations found in marine operations.

3.2 Ultrasonic Level Sensors

Ultrasonic sensors offer a cost-effective, reliable solution for open tank draft measurement or in exposed ballast water systems.

✅ Explosion-Proof Design

Certified for hazardous zones (e.g., Ex d IIC T6 Gb), ultrasonic sensors are suitable for use in flammable atmospheres like fuel tanks or gas vented compartments.

✅ Non-Contact Technology

Like radar, ultrasonic sensors measure liquid levels from a distance, eliminating contamination risks or mechanical wear.

✅ Durability

Made from PVDF or similar corrosion-resistant materials, ultrasonic sensors can operate in chemically aggressive marine environments.

✅ Modular Construction

Many models feature modular, split-type designs, simplifying maintenance and replacement in confined spaces or while at sea.

✅ RS485 Communication

Standard digital output (e.g., RS485 Modbus) ensures seamless integration with shipboard automation and monitoring systems.

4. Application in Ship Draft Monitoring Systems

Both radar and ultrasonic level sensors are installed in ballast tanks or dedicated draft pipelines to provide continuous data on:

Fore and aft draft

Port and starboard list

Trim and heel adjustments

A centralized monitoring system can automatically interpret these values to:

● Stabilize Ballast Water Distribution

Accurate real-time data allows automated ballast control to maintain optimal trim and stability throughout the voyage.

● Ensure IMO Compliance

Precise draft readings help vessels comply with international maritime regulations related to ballast water management and safe loading.

● Enhance Maritime Safety

By preventing excessive trim or heel, and maintaining proper load distribution, these systems reduce the risk of capsizing, flooding, or cargo loss.

5. Conclusion

Accurate draft measurement is essential for safe, efficient, and regulation-compliant maritime operations. Radar and ultrasonic level sensors provide robust, high-performance solutions tailored to the challenges of marine environments.

Whether utilizing radar sensors equipped with adaptive signal processing and Bluetooth communication, or explosion-proof ultrasonic sensors with modular construction, these technologies guarantee long-term reliability and precision.

Investing in high-quality level measurement systems is not just about compliance—it’s about ensuring that your vessel sails smarter, safer, and more efficiently across the globe.