1. Introduction

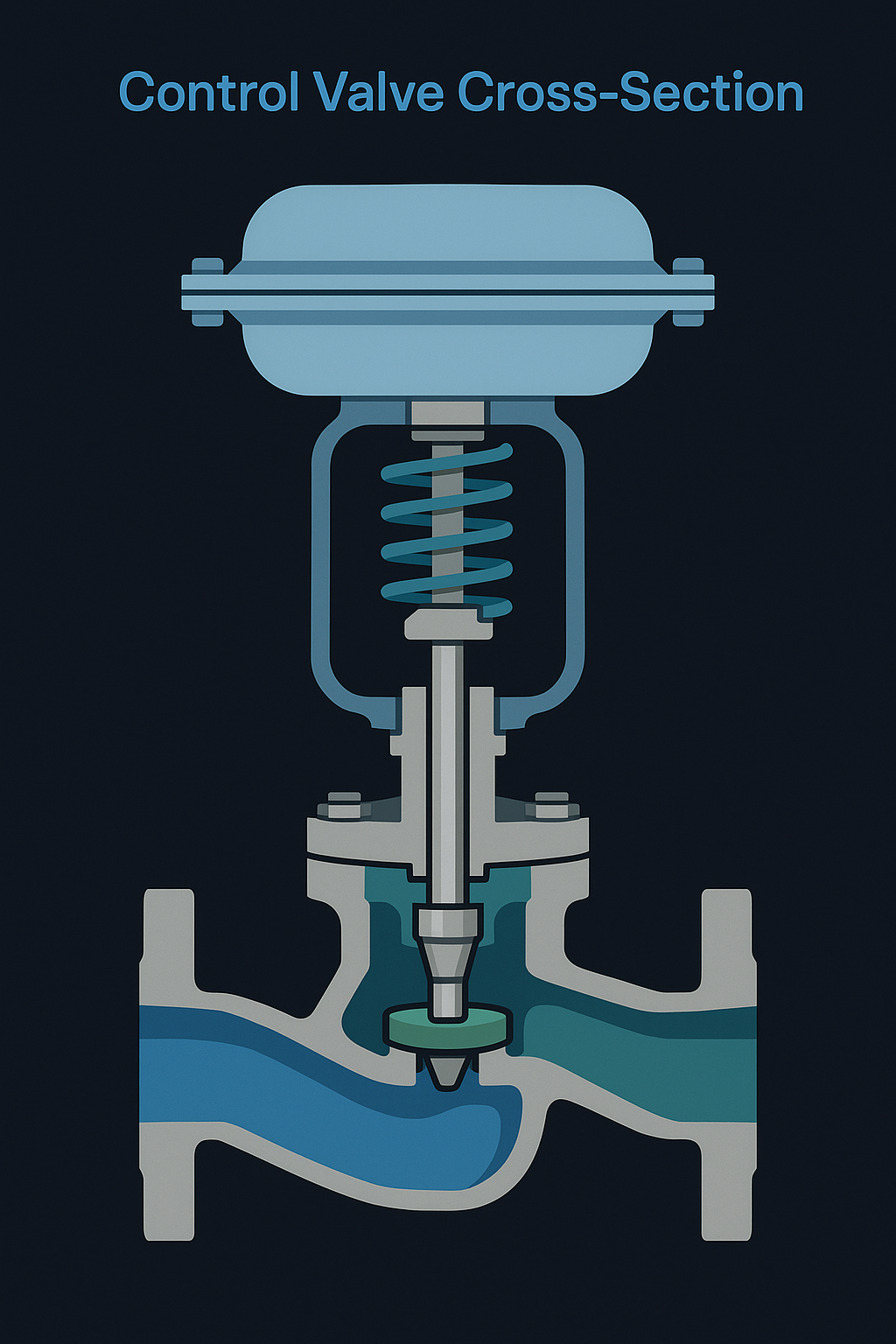

The performance, reliability, and service life of a control valve largely depend on the correct selection of trim materials and accessories. Inappropriate material or accessory choices can lead to corrosion, erosion, cavitation damage, and reduced control accuracy. This guideline provides practical selection criteria for various industrial process conditions.

2. Trim Material Selection

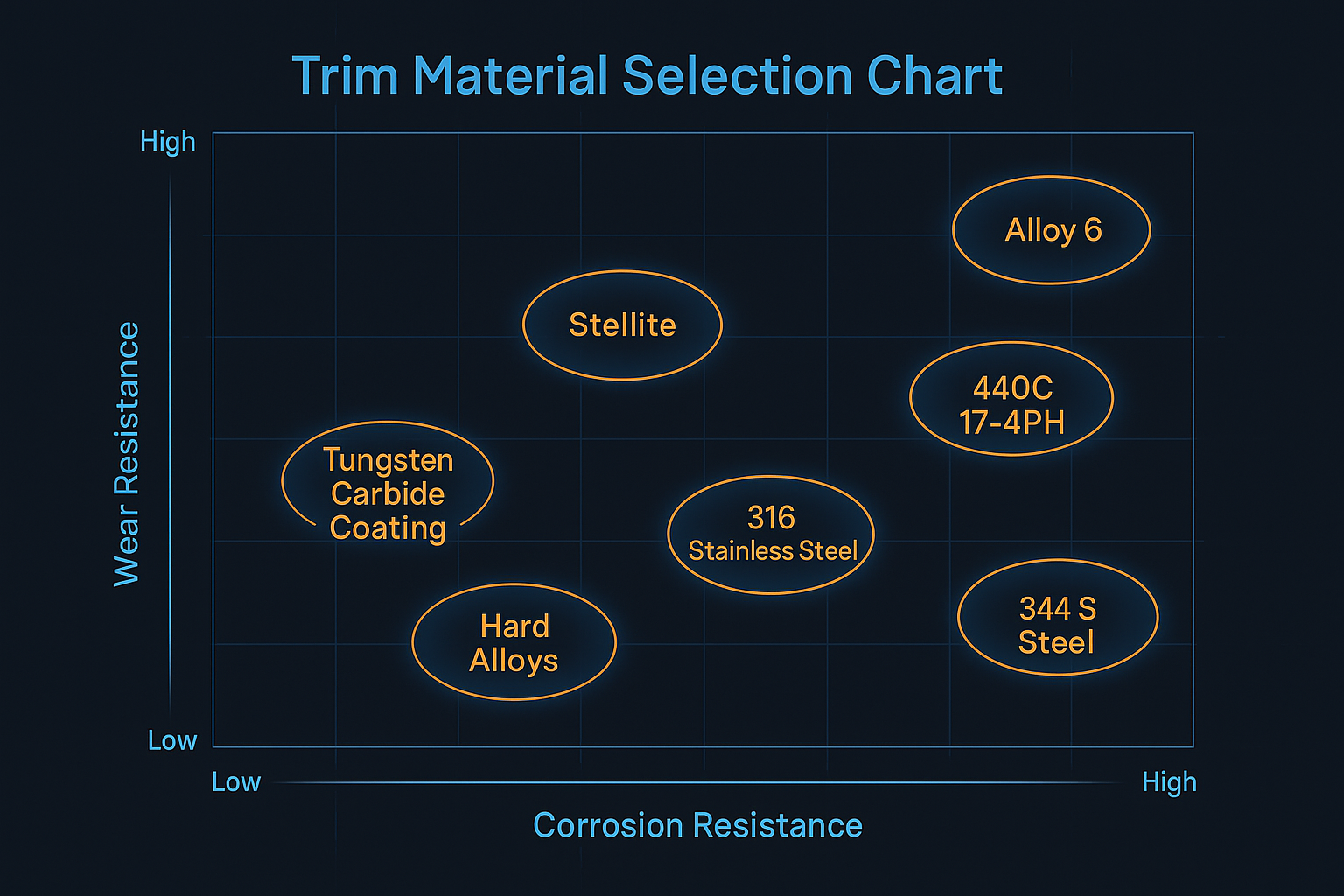

| Process Condition | Recommended Material | Remarks |

|---|---|---|

| General service | 316 Stainless Steel (316SS) | Excellent corrosion resistance, widely used for most media |

| Corrosive fluids | Select corrosion-resistant alloys according to fluid type, concentration, temperature, and pressure | For H₂S service: 304SS, 316SS, or Alloy 6 |

| High-temperature, high-pressure, flashing, cavitation, or severe erosion | Stellite hard-facing or other hard alloys | Enhances wear resistance and prevents surface damage |

| Steam service with ΔP > 700 kPa (100 psi) | S44004 (440C) or S17400 (17-4PH SS) | Also suitable for high-pressure boiler condensate |

| Gas service with ΔP > 1000 kPa (150 psi) and inlet vaporization rate > 3% wt | S44004 (440C) or S17400 (17-4PH SS) | Ensures mechanical strength under high stress |

| Any service with ΔP > 1700 kPa (250 psi) | Hard stainless steel or hard-facing alloy | Required for severe operating conditions |

| Temperature > 310°C (600°F) with solids in media | Hard alloys (e.g., tungsten carbide coating) | Prevents particle-induced erosion |

| Oil/water level control (e.g., crude oil separators) | Tungsten carbide coating or solid hard alloy | Improves durability in multiphase flow |

Note: Trim plugs (excluding stems) should be machined or cast from solid bar stock — split or hollow plugs are not recommended.

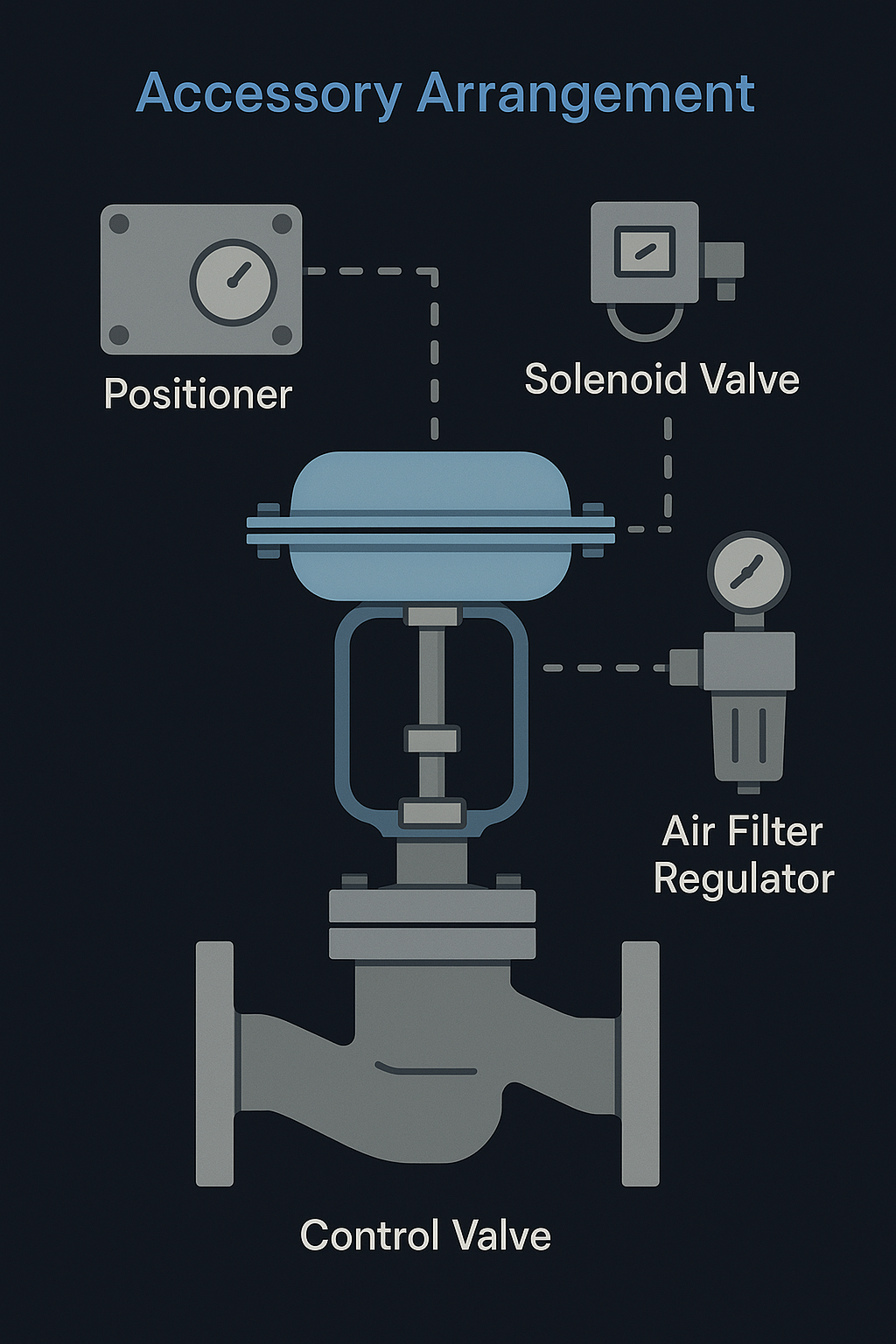

3. Accessory Selection

| Accessory | Selection Criteria | Remarks |

|---|---|---|

| Valve Positioner | Smart type, 4–20 mA DC with HART protocol, direct acting | Ensures precise positioning |

| Handwheel Mechanism | For valves without shut-off and bypass valves | Not to be used for mechanical travel limits unless specified |

| Pneumatic Booster/Relay | For fast response control systems or large-diameter valves | Increases actuator speed and output pressure |

| Limit Switch | Proximity dry contact or NUMAR type | Required for interlock position indication |

| Valve Position Transmitter | When exact valve position monitoring is needed | Suitable for remote control or feedback |

| Solenoid Valve | Low power (<4W), 3-way or 4-way | For remote control, process interlock, or emergency shutdown |

| Explosion-Proof Rating | All electrical components (positioners, converters, solenoids, limit switches) must comply with applicable explosion-proof codes | Ensures safety in hazardous areas |

| Instrument Air Receiver | Must comply with TSGR0004 | Consider adding a pressure switch for SIL-rated systems to monitor low air pressure or supply failure |

4. Explosion-Proof and Safety Requirements

All electrical accessories used in hazardous areas must meet the required explosion-proof certification.

The air supply system should be designed with redundancy and monitoring, especially for valves critical to safety instrumented functions.

Pressure switches should be included in SIL applications to detect air supply failure.