Introduction

Turbine flow meters are widely used for measuring the flow rate of liquids and gases in various industrial applications, including water treatment, oil and gas, chemical processing, and food and beverage industries. Selecting the right turbine flow meter requires careful consideration of multiple factors to ensure optimal performance, longevity, and accuracy. This article outlines the key aspects that should be evaluated when choosing a turbine flow meter.

1. Understanding Turbine Flow Meter Operation

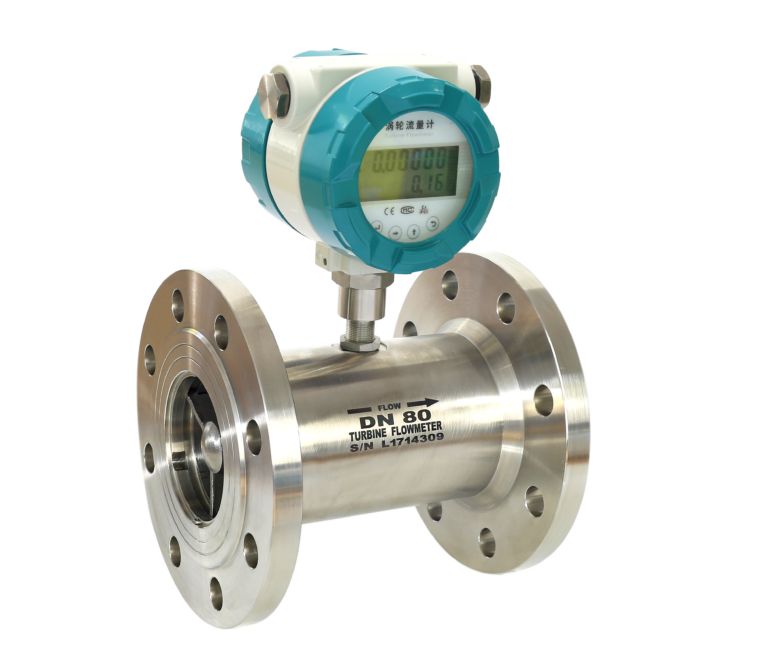

A turbine flow meter operates on the principle of fluid passing through a rotating turbine wheel, where the rotational speed of the turbine is proportional to the flow rate. The movement of the turbine generates pulses, which are then converted into flow measurements.

Turbine flow meters are well-suited for clean, low-viscosity fluids with consistent flow conditions. However, they are sensitive to changes in viscosity, turbulence, and the presence of solid particles, which may affect measurement accuracy.

2. Key Selection Criteria

2.1 Fluid Properties

Type of Fluid: Turbine flow meters are ideal for non-corrosive and non-viscous fluids such as water, fuel, oils, and gases. If the fluid is corrosive, special material options such as stainless steel or Hastelloy should be considered.

Viscosity: These meters are most accurate for fluids with viscosities below 5 cP. Higher viscosity fluids can cause drag on the turbine blades, leading to measurement errors.

Presence of Particles: Solid particles in the fluid can damage the turbine blades. It is recommended to install a filtration system upstream to prevent clogging and wear.

2.2 Flow Rate and Measurement Range

Operating Flow Range: The selected turbine flow meter should accommodate the normal and peak flow rates in the system. Flow meters have a minimum and maximum range; operating outside this range can lead to inaccurate readings or mechanical damage.

Low Flow Sensitivity: Some turbine meters have a high starting threshold, meaning they may not be suitable for very low flow applications.

2.3 Operating Conditions

Temperature and Pressure Ratings: The material of the flow meter should withstand the operating temperature and pressure of the system. High-temperature applications may require specialized bearings and construction materials.

Environmental Considerations: If the flow meter is exposed to extreme environments (e.g., explosive atmospheres), selecting an explosion-proof or weather-resistant model is crucial.

2.4 Accuracy and Calibration

Accuracy Level: Standard turbine flow meters have an accuracy of ±0.5% to ±1.5% of reading. For critical applications such as custody transfer, higher accuracy models (±0.2% or better) should be used.

Repeatability: The ability of the meter to provide consistent readings under identical conditions is important, especially for process control applications.

Calibration: Regular calibration is necessary to maintain accuracy over time. Consider whether on-site or factory calibration services are available for the chosen model.

2.5 Installation Considerations

Straight Pipe Requirements: To ensure laminar flow and accurate readings, turbine flow meters typically require straight pipe sections upstream (10D) and downstream (5D), where D is the pipe diameter.

Mounting Orientation: Some models require horizontal installation, while others can be installed vertically.

Connection Type: Turbine meters come with different connection options, including threaded, flanged, or wafer-style connections. The choice depends on system compatibility and ease of maintenance.

2.6 Output and Communication Options

Pulse Output: Generates frequency signals proportional to the flow rate. Used for simple monitoring applications.

Analog Output (4-20mA): Allows integration with industrial control systems such as PLCs and SCADA.

Digital Communication (RS485, Modbus, HART): Enables remote monitoring and data logging.

2.7 Power Supply Options

Battery-Powered: Suitable for remote locations where power is not available.

External Power (24V DC or 220V AC): Required for continuous operation in industrial settings.

2.8 Special Features and Enhancements

Temperature and Pressure Compensation: Helps correct variations in flow measurement due to environmental changes, especially for gas applications.

Flow Conditioning Elements: Used to reduce turbulence and improve measurement accuracy.

Bi-Directional Measurement: Some models support flow measurement in both directions.

3. Application-Specific Selection

3.1 Water and Wastewater Applications

Turbine flow meters are commonly used in clean water applications but may not be suitable for wastewater due to potential debris that could damage the turbine.

3.2 Oil and Gas Industry

In the petroleum sector, turbine meters are used for fuel monitoring, crude oil measurement, and refined product distribution. They must be explosion-proof and resistant to high pressures.

3.3 Chemical and Pharmaceutical Industry

Chemical compatibility and precision measurement are crucial. Special coatings or exotic materials (e.g., PTFE-lined meters) may be required to handle aggressive chemicals.

3.4 Food and Beverage Processing

Hygienic turbine flow meters with sanitary connections are necessary for applications requiring compliance with FDA and 3A sanitary standards.

Conclusion

Selecting the right turbine flow meter involves evaluating fluid properties, flow range, accuracy, installation conditions, and output requirements. Considering factors such as material compatibility, power supply, and communication interfaces will help ensure that the chosen flow meter provides reliable and precise measurements. By carefully assessing these aspects, users can optimize their flow measurement system for efficiency and longevity.