Liquid level measurement in harsh industrial environments, such as the metallurgical and power industries, presents unique challenges due to extreme temperatures, high pressures, and corrosive media. Magnetic flap (magnetic level) gauges have become an industry-standard solution, providing reliable and accurate measurements. This article provides guidance on selecting suitable magnetic level gauges, tailored specifically for metallurgical and power industry applications.

1. Suitable Models and Requirements for the Metallurgical Industry

High-Temperature and Corrosive Environments

The metallurgical industry frequently involves operations under extremely high temperatures (such as melting furnaces, reaction vessels) and exposure to highly corrosive media. Therefore, selecting a high-temperature resistant magnetic level gauge is critical.

Recommended Model:

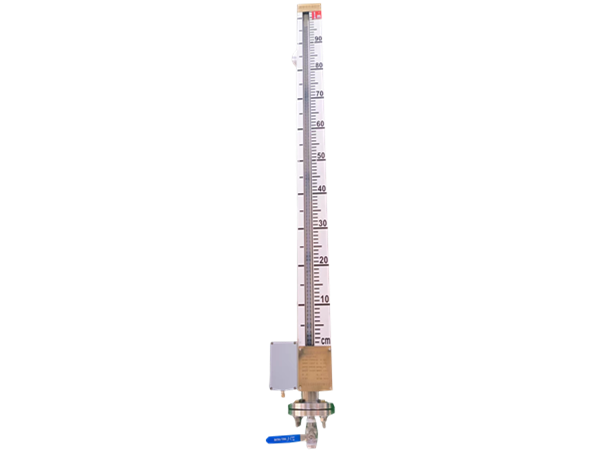

UHZ/158 High-Temperature Magnetic Level Gauge

Specifically designed for high-temperature conditions common in metallurgy.

Material: 304SS stainless steel, resistant to corrosion.

Operating temperature: ≥500℃, suitable for melting furnaces, reaction vessels, storage tanks, etc.

Power supply: 220VAC standard supply.

Installation Method:

Top-mounted configuration:

Recommended for underground tanks or vessels without side openings.

Ensures non-contact measurement from the top, minimizing leakage risk through sealing surfaces.

Additional Features:

IP68 protection rating recommended for improved safety and reliability in harsh conditions.

Multi-point alarm switches can be integrated to facilitate limit control and emergency response.

2. Suitable Models and Requirements for the Power Industry

High Pressure and Complex Operating Conditions

Power generation environments are typically characterized by high-pressure containers (boilers, steam drums) and elevated-temperature steam conditions. It is essential to select a magnetic level gauge capable of handling high pressure and temperature reliably.

Recommended Model:

High-Pressure Magnetic Level Gauge

Material: Optimized materials such as 316L or 304SS stainless steel for enhanced durability and corrosion resistance.

Capable of withstanding medium to high pressures and compatible with high-temperature steam.

Installation Method:

Flexible mounting options:

Side-mounted configuration: For above-ground vessels, easy for maintenance and monitoring.

Top-mounted configuration: Preferred for underground tanks to ensure minimal interference and enhanced measurement stability. Installation verticality within 3° ensures optimal accuracy.

Additional Features:

Equipped with liquid level transmitters or reed-resistor type sensors to convert liquid level readings into standard 4-20mA signals for remote monitoring and automated control systems.

Certified explosion-proof design (Ex-proof rating) recommended for power industry applications due to the presence of combustible gases or dust.

3. Key Parameters and Considerations for Selection

When choosing magnetic level gauges, consider the following essential parameters:

Medium Characteristics:

Clearly define medium temperature (metallurgy industry typically ≥500℃), corrosiveness (highly acidic or alkaline environments require 304SS or 316L stainless steel), and viscosity (avoid high-viscosity fluids).

Vessel Conditions:

Pressure rating (high-pressure vessels in power industry require specially rated gauges).

Installation space constraints (choose top or side mounting accordingly).

Additional Functional Requirements:

Safety protections such as IP68 ratings for metallurgy and explosion-proof certifications for power industry settings.

Intelligent features, including remote transmitters for power industry and multi-point alarm functionality for metallurgy applications.

4. Typical Application Scenarios

| Industry | Typical Scenario | Recommended Model & Features |

|---|---|---|

| Metallurgical | High-temperature melting furnaces, underground storage tanks | Top-mounted high-temperature magnetic gauge (304SS, IP68 protection) |

| Power | High-pressure boilers, steam drums | High-pressure gauge with remote transmitter (316L, Ex-proof) |

Conclusion

For the metallurgical industry, prioritize selecting a top-mounted, high-temperature magnetic flap level gauge (model UHZ/158). For the power industry, opt for high-pressure gauges with integrated remote transmission capabilities. Accurate and careful selection based on the specific medium properties, pressure requirements, and installation constraints will ensure optimal performance and reliability.