In industries such as petrochemicals, coal mining, dust processing, fine chemicals, and logistics, explosive environments are always a potential risk. To achieve safe production, it is essential to identify risks at the source. The classification of hazardous explosive areas is a crucial precondition for all explosion-proof design, equipment selection, ventilation system layout, and operational management. A scientific classification can clearly define the boundaries and levels of hazardous environments, allowing engineering measures to be targeted, thereby reducing the probability of ignition sources and minimizing accident risks.

This article systematically reviews the principles of hazardous area classification, the standard framework, classification rules for gas and dust environments, influencing factors, and key points for practical implementation.

Principles of Hazardous Area Classification

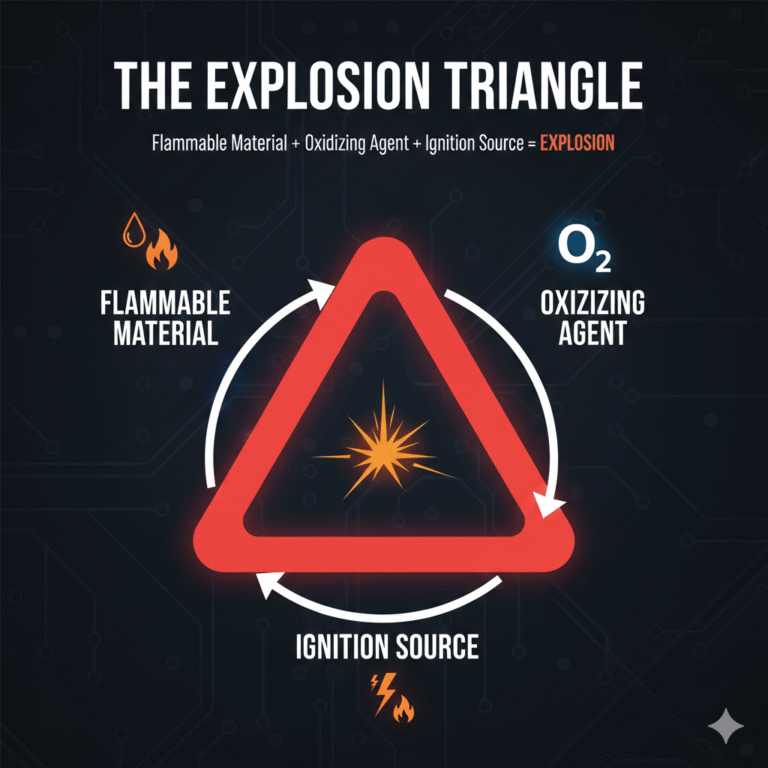

1. The Three Essential Elements of Explosion

In industrial scenarios, the simultaneous presence of flammable materials, oxidizing agents, and ignition sources is the fundamental condition for an explosion. These three elements include:

Flammable materials: Such as natural gas, gasoline vapors, coal dust, or metal dust.

Oxidizing agents: Typically air, where oxygen content is critical for explosion propagation.

Ignition sources: Including electrical sparks, mechanical friction, static electricity, or high-temperature surfaces.

When these elements are present in the right proportions, an explosion hazard exists. Hazardous area classification essentially evaluates the probability of these three elements occurring simultaneously, based on the frequency and duration of their presence. The longer and more frequent the occurrence, the higher the risk level, leading to the classification of different zones for management purposes.

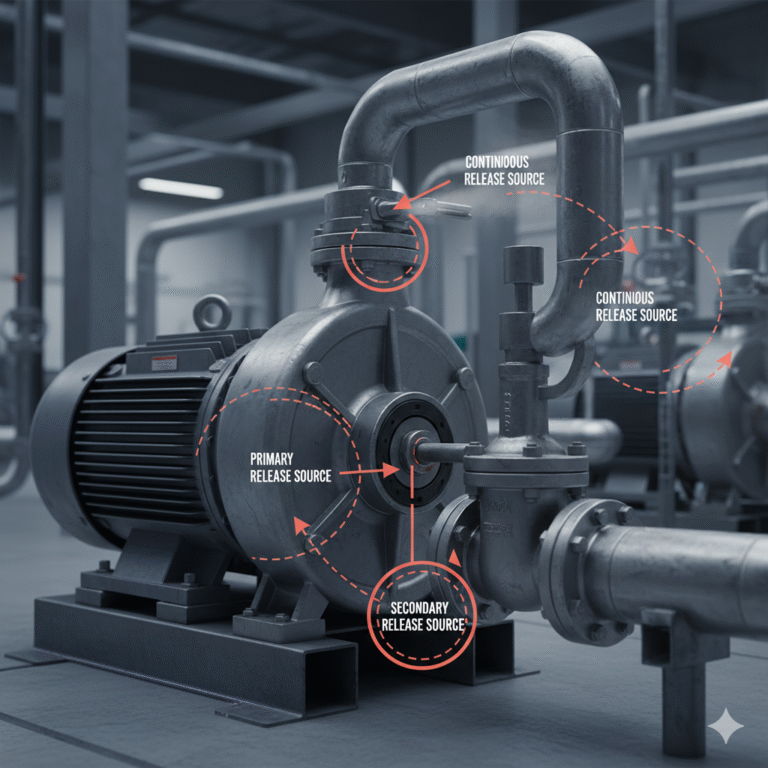

2. Release Sources

Release sources refer to areas where flammable substances might leak, such as pump seals, valves, flanges, breathing valves, or dust conveyor joints. These can be classified based on their release frequency and duration:

Continuous release sources: Present at all times (e.g., gas vapor in a storage tank).

Primary release sources: Occur during normal operations and may leak occasionally (e.g., pump seals).

Secondary release sources: Only leak in exceptional circumstances (e.g., flange leaks).

The higher the release frequency and duration, the higher the danger level of the area.

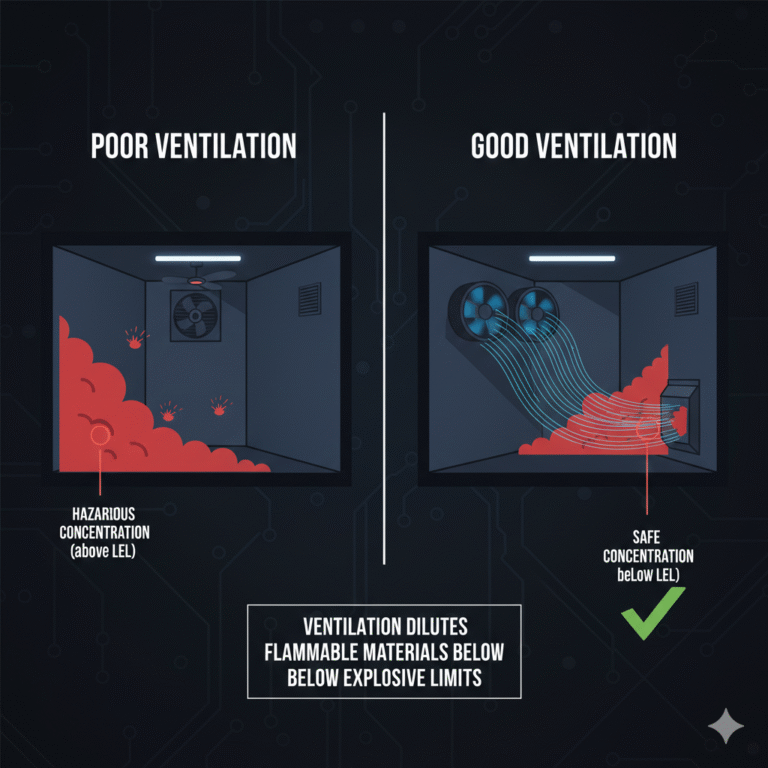

3. Ventilation Conditions

Ventilation plays a crucial role in diluting flammable materials to below hazardous concentrations. Both natural ventilation (airflow variation) and mechanical ventilation (fans) are critical factors. Good ventilation can lower the concentration of flammable substances, significantly reducing the area’s risk if it maintains concentrations below the explosive limit (e.g., methane LEL ≈ 5%).

4. Economic and Technical Balance

The classification of hazardous areas must balance safety and cost-efficiency. A classification that is too narrow might overlook risks, while one that is too broad can lead to unnecessarily high equipment costs. The best approach is to perform a comprehensive evaluation based on the nature of the flammable materials, release probabilities, spatial structure, and operational experience to achieve a classification that meets regulatory requirements while being feasible for engineering implementation.

Gas and Vapor Environment Area Classification

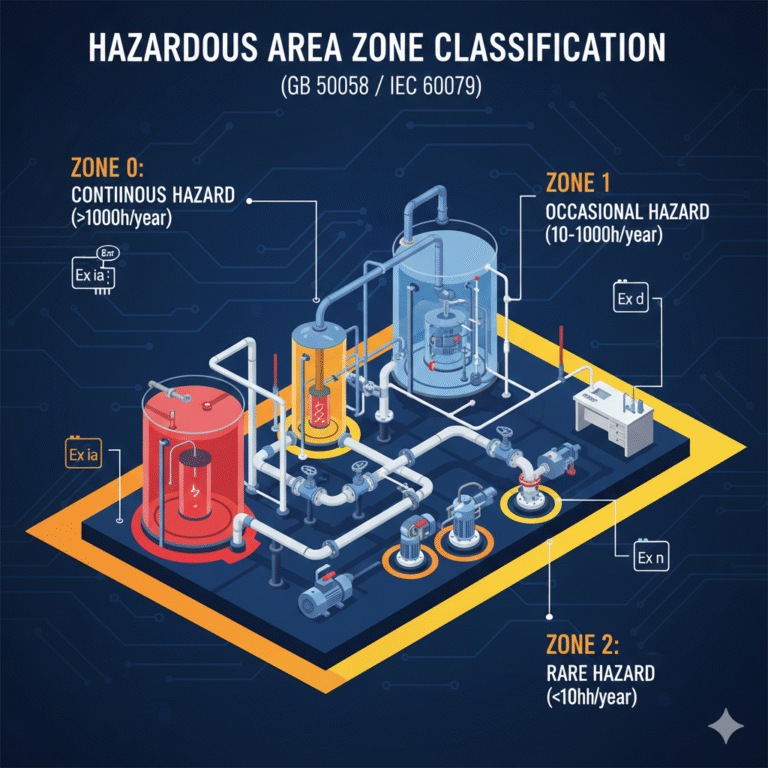

In China, the primary method used for classification is the Zone system, including Zones 0, 1, and 2:

1. Zone 0: Continuous Hazardous Zone

In this zone, flammable gases or vapors are present continuously or frequently, for over 1,000 hours annually. Common examples include the internal gas phase of storage tanks, reactors, or underground spaces. Equipment must be of the highest safety level, typically intrinsically safe (Ex ia), which ensures that no fault can produce an ignition source by limiting energy (current, voltage).

2. Zone 1: Occasionally Hazardous Zone

This zone is where flammable gas clouds might occur during normal operations, often related to process fluctuations or equipment leakage. Examples include pump rooms (seal leaks), valve areas (operational leakage), and gas stations (gasoline vapor). Explosion-proof (Ex d), increased safety (Ex e), or intrinsically safe (Ex ib) equipment is typically used in these areas.

Explosion-proof (Ex d): Equipment can withstand internal explosion pressures and prevent flame propagation.

Increased safety (Ex e): This reduces arcing and lowers temperature to enhance safety.

3. Zone 2: Rare Hazardous Zone

Flammable mixtures are only likely to form in this zone under abnormal conditions or leaks. Common examples include the periphery of storage tanks or well-ventilated laboratory areas. Equipment used in this zone should be non-sparking (Ex n), meaning it won’t produce arcs or excessive heat during normal operation.

4. Gas Diffusion Characteristics and Area Extent

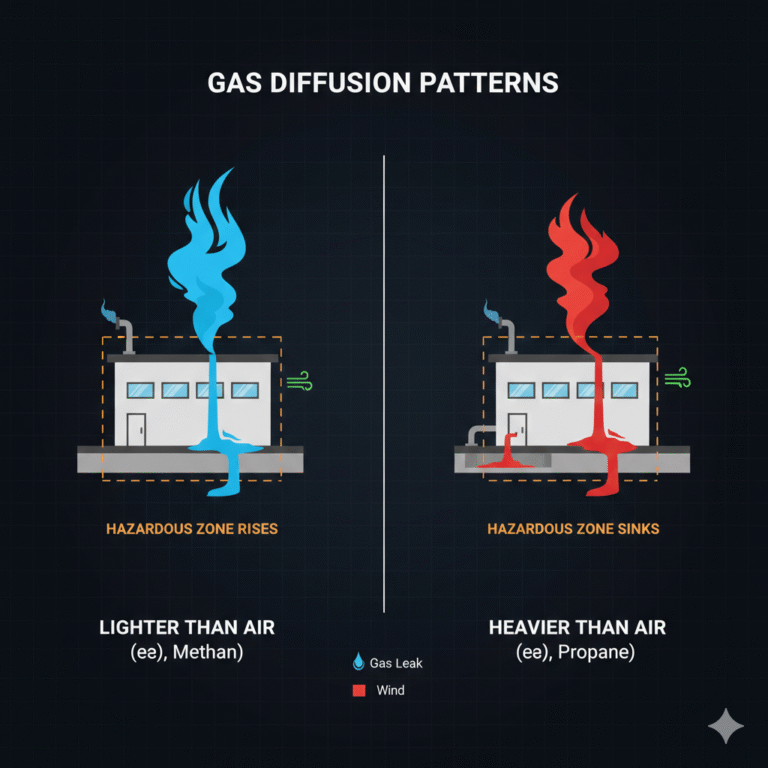

The relative density of gases (compared to air) influences their diffusion:

Heavier than air (Density > 1): Gases like propane and butane tend to accumulate at ground level.

Lighter than air (Density < 1): Gases like hydrogen and methane rise upwards.

The height of the hazardous zone is typically set based on these characteristics. For highly volatile substances, diffusion might spread further, and the extent of the zone should be assessed based on material properties. Diffusion patterns also depend on wind speed and obstructions.

Dust Environment Area Classification

Unlike gas explosions, dust explosions occur when dust clouds reach an explosive concentration. The smaller the dust particles and the drier they are, the easier it is to form explosive dust clouds.

1. Zone 20: Continuous Dust Cloud Zone

In this zone, dust is suspended in the air for prolonged periods. Examples include internal areas of flour mills, coal storage, and metal powder mixing chambers. Due to the risk of secondary explosions (the first explosion can disturb settled dust), the highest protective level is required.

2. Zone 21: Occasionally Suspended Dust Cloud Zone

Dust is occasionally suspended during operations, such as in loading/unloading points or transport systems. Dust explosion-proof (Ex tD) electrical equipment is typically used, and surface temperature must be controlled to prevent ignition.

3. Zone 22: Rare Dust Cloud Zone

Dust is generally settled and only becomes airborne during disturbances or faults. This is commonly found in corners, outside dust collectors, or storage areas. The particle size, humidity, and composition of the dust significantly affect the explosion risk.

Standard System

1. National Standards

China’s main standards for explosion-proof electrical equipment and hazardous area classification include:

GB 50058: Design Code for Electrical Installations in Explosive Atmospheres.

GB 3836: Explosive Atmosphere series, detailing equipment categories, markings, and requirements.

Industry-specific standards, such as those for coal mines and food processing, also exist.

2. International Standards

IEC 60079: International standard for explosive atmospheres, covering both gas and dust environments.

ATEX (EU): Mandatory regulations for equipment and area management in explosive environments.

NFPA/NEC (USA): A classification system based on Class/Division methodology, similar in logic to the Zone system.

3. Factors Affecting Area Classification

Key factors influencing classification include:

Properties of flammable substances (flashpoint, explosive limits, dust characteristics).

Release source parameters (leak rate, pressure, temperature).

Ventilation conditions (whether natural or mechanical ventilation is sufficient to prevent hazardous concentrations).

Space structure (closed or open environments, obstacles that may trap gases).

Equipment aging (seal wear, corrosion, vibration) necessitating periodic reviews and updates.

Implementation Guidelines

1. Equipment Selection Logic

Explosion-proof equipment must match the classified area and the type of gas or dust present, including:

Area Classification (Zone)

Explosion Protection Type (Ex ia, Ex d, Ex e, Ex tD)

Gas Groups (IIA, IIB, IIC—most stringent for hydrogen)

Temperature Classifications (T1 to T6, indicating maximum surface temperature)

2. Ventilation System Validation

Ventilation must ensure the concentration of flammable gases remains below the explosive limit (LEL). Verification can be done using site testing, gas diffusion models, or CFD simulations.

3. Area Mapping and On-Site Signage

The classification map should indicate horizontal and vertical boundaries, release source locations, and required equipment types. Clear signage should be placed on-site to prevent workers from entering incorrect zones.

4. Common Misconceptions

Ventilation inadequacy leading to downgraded hazard classifications.

Dust accumulation being overlooked as a safety hazard.

Incorrect equipment certification matching, especially between gas and dust environments.

These common errors often lead to serious accidents and should be strictly avoided.