1. Introduction

In Safety Instrumented Systems (SIS), Safety Integrity Level (SIL) quantifies the required risk reduction.

However, even within the same SIL rating, different configurations of pressure transmitters can significantly impact practical safety performance, reliability, and maintenance complexity.

This article explores:

Why different configurations matter under the same SIL

Common pressure transmitter setups

Their relative safety differences

Engineering case examples

2. Understanding SIL and Transmitter Configuration

SIL measures probability of failure on demand (PFD) or probability of dangerous failure per hour (PFH).

Transmitter configuration refers to the physical setup and logic of one or multiple pressure transmitters used to achieve the safety function.

Even if multiple setups meet the mathematical PFD requirements for SIL2 or SIL3, their real-world performance can differ in:

Failure detection speed

Maintenance needs

False trip rates

Resilience to common-cause failures

3. Typical Pressure Transmitter Configurations

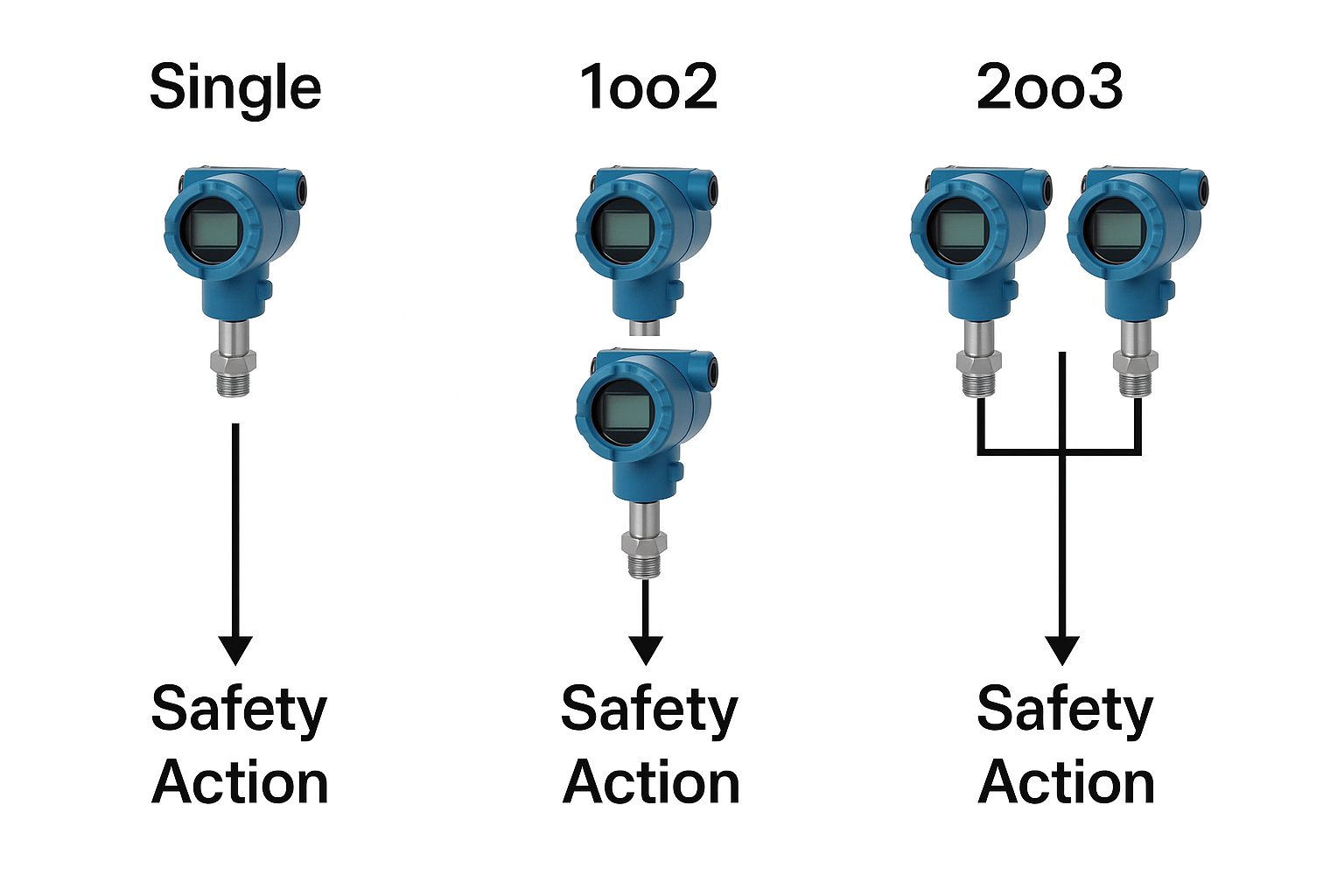

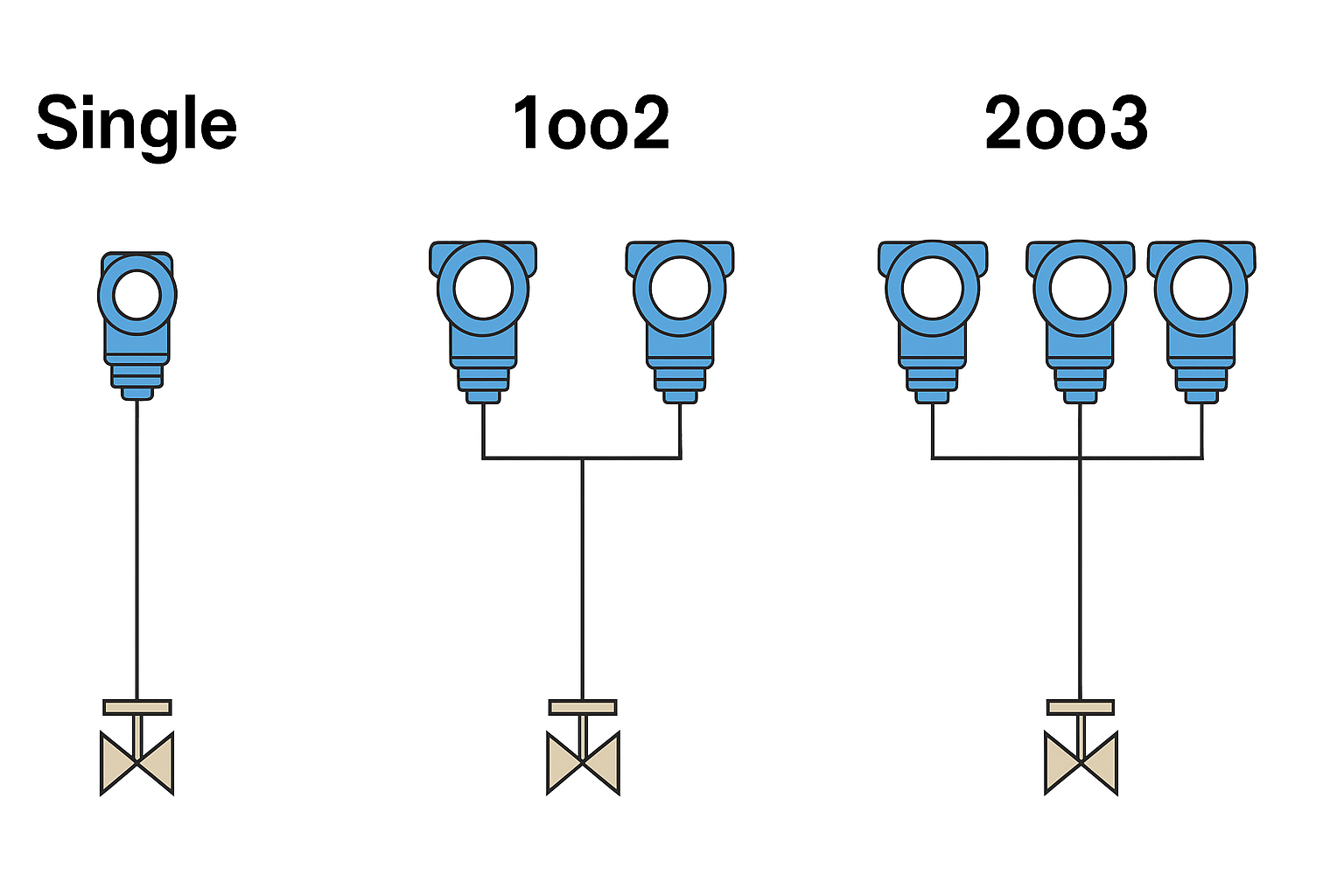

| Configuration | Description | Key Characteristics |

|---|---|---|

| Single Transmitter | One transmitter triggering the safety action | Simple, low cost, but single-point failure risk |

| 1oo2 (One-out-of-Two) | Two transmitters, any one triggers action | Higher availability, tolerant to one failure |

| 2oo3 (Two-out-of-Three Voting) | Three transmitters, at least two must agree | High safety, detects failure early, reduces false trips |

| Redundant Single Loop | Main + backup transmitter, manual or automatic switchover | Improves reliability but still needs manual testing |

| Smart Diagnostics (Heartbeat Technology, etc.) | Advanced transmitter with self-diagnosis features | Enhances fault detection without extra hardware |

4. Safety Differences Analysis

4.1 Single Transmitter

Pros: Lowest cost, simplest installation.

Cons: A dangerous undetected failure will compromise the safety function completely.

Typical: Only acceptable for low-demand SIL1 applications or where redundancy is not economically feasible.

4.2 1oo2 Redundancy

Pros: System remains functional if one transmitter fails.

Cons: Potential for spurious trips if one device malfunctions and triggers the safety function unnecessarily.

4.3 2oo3 Voting

Pros:

Highest fault tolerance.

Early fault detection possible (automatic deviation monitoring).

Greatly reduces nuisance trips.

Cons:

Higher initial cost and maintenance complexity.

Requires careful installation to avoid common-cause failures (e.g., same tapping point, same cable route).

4.4 Redundant Single Loop

Pros: Moderate improvement over single transmitter.

Cons: Backup unit needs regular manual proof testing; no automatic fault detection between tests.

4.5 Smart Diagnostics

Pros:

Detects sensor drift, blockage, or calibration loss.

Lower cost than full 2oo3 hardware redundancy.

Cons:

Only detects certain types of failures, cannot cover total hardware failures.

5. Engineering Case Studies

Case 1: SIL2 Pressure Protection for Steam Drum

Original Design: Single transmitter

Issue: Failure not detected between proof tests → unexpected high drum pressure

Improvement: Upgraded to 1oo2 architecture

Result: Availability increased, SIL2 requirement still satisfied, annual maintenance updated to check both transmitters.

Case 2: SIL3 High-Pressure Shutdown in Offshore Platform

Design: 2oo3 voting of three transmitters from different manufacturers, separate tap points.

Challenge: Environmental stress (corrosion, vibration).

Action: Introduced advanced diagnostics, staggered maintenance cycles.

Result: Zero shutdown incidents for three years, even in extreme offshore conditions.

Case 3: SIL2 Ammonia Tank Level Protection (Using Pressure Measurement)

Design: Redundant single loop, with automatic switchover.

Issue: Backup transmitter not tested for 18 months → detected failure during audit.

Lesson: Even “redundant” systems need periodic proof testing to ensure actual availability.

6. Practical Recommendations

For SIL1: Single transmitter with smart diagnostics may be sufficient.

For SIL2: 1oo2 is recommended; single transmitter discouraged unless risk assessment proves acceptable.

For SIL3: Always prefer 2oo3 voting or advanced diagnostics + partial redundancy.

Always mitigate common-cause failures:

Physically separate cabling

Use different measurement taps if possible

Diversify vendors or sensor types for higher robustness.

Conclusion

Even under the same SIL target, different pressure transmitter configurations lead to very different safety performances in real projects.

Proper selection of configuration not only achieves the formal SIL target but also ensures reliable, sustainable, and cost-effective system operation.