RF Capacitance (or RF Admittance) Level Switches are vital instruments for industrial liquid level measurement. The core principle behind their operation is based on changes in capacitance. A rod-type RF capacitance probe measures the change in capacitance between the probe and the container wall to determine the level, ensuring reliable liquid level monitoring. Although this measurement method is well-established in industrial applications, the impact of probe diameter on the instrument’s sensitivity remains a key concern during engineering selection and on-site commissioning. This article systematically explores the relationship between probe diameter and capacitance changes from the perspective of principle, formula, practical conditions, and engineering applications.

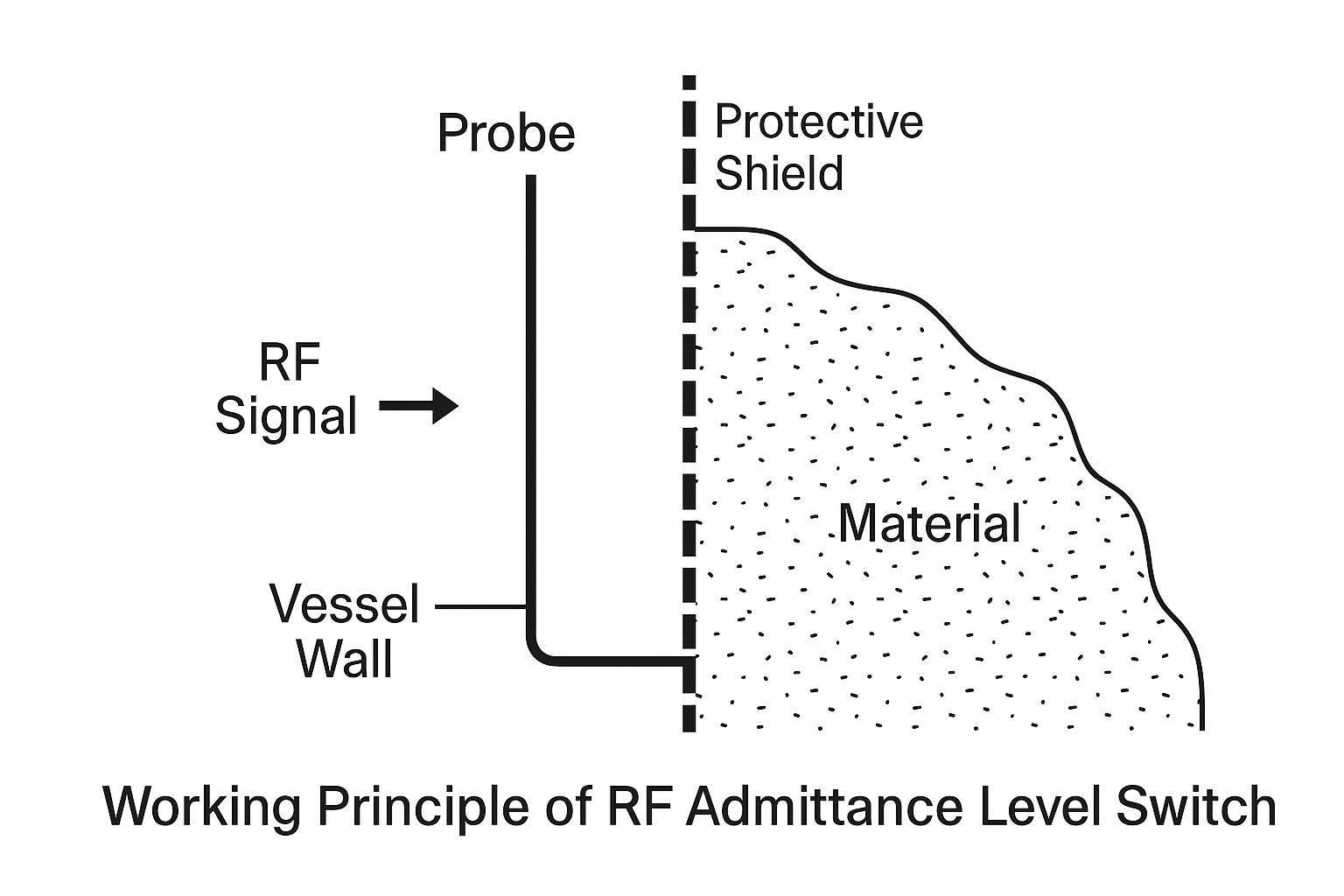

1. Measurement Principle of RF Capacitance Level Switches

The core measurement principle of RF capacitance level switches is capacitance variation. The probe, installed inside the container, forms a parallel capacitor with the container wall, where the two plates are the probe and the container wall. When the medium in the container changes (such as liquid rising or filling with solid materials), the dielectric constant between the plates changes, causing capacitance variation. The basic formula for capacitance can be expressed as:

Where:

is the capacitance value

is the dielectric constant of the medium

is the plate area (for rod probes,

is related to the surface area of the probe)

is the distance between the plates (related to the container diameter minus the probe diameter)

From this formula, it’s clear that the probe diameter (

), container diameter (

), and the dielectric constant (

) directly influence the capacitance change sensitivity, making them key factors in determining the instrument’s sensitivity.

2. Impact of Probe Diameter on Capacitance Changes

In practical engineering, we typically focus on two aspects:

The relationship between capacitance change (

) and liquid level height (

)

The impact of probe diameter on sensitivity

To analyze this relationship, we assume a container diameter

and a dielectric constant

, considering different probe diameters:

Scenario 1: Probe Diameter

When the probe diameter is 10 mm, the capacitance change

in relation to liquid level height

can be approximately expressed as:

As the liquid level rises, the capacitance increases linearly. A larger probe diameter results in a larger surface area, which significantly enhances sensitivity.

Scenario 2: Probe Diameter

When the probe diameter is reduced to 8 mm, the relationship between capacitance change and liquid level is similar, but since the plate area is smaller, the sensitivity decreases:

From this comparison, it is evident that a larger probe diameter results in a more noticeable capacitance change, hence higher sensitivity. In engineering practice, if greater sensitivity to liquid level changes is required, a larger diameter probe should be selected, while considering the matching with the container diameter to avoid installation space limitations.

3. Engineering Analysis of Capacitance Sensitivity

Based on the formula above, we can summarize the following key points:

Probe Diameter and Sensitivity: The probe diameter (

) is positively correlated with sensitivity. A larger diameter increases the plate area, which amplifies capacitance variation and leads to more sensitive responses.

Container and Probe Diameter Ratio: The ratio between the container diameter (

) and probe diameter (

) affects sensitivity. The closer

is to

(i.e., the smaller the distance between the plates), the higher the sensitivity. If the container diameter is too large relative to the probe diameter, capacitance changes become smaller, leading to delayed or less accurate level detection.

Effect of Dielectric Constant: The dielectric constant (

) significantly influences sensitivity. A higher dielectric constant results in a larger capacitance change, thus improving instrument sensitivity. For low-dielectric media (such as powders or low-conductivity liquids), larger probe diameters or compensation circuits can be used to improve sensitivity.

In real-world applications, aside from theoretical calculations, on-site installation conditions, medium type, and special requirements such as corrosion or adhesion resistance need to be considered comprehensively.

4. Engineering Selection Recommendations

Based on the capacitance principle and the relationship between probe diameter and sensitivity, the following selection recommendations can be made:

For High Sensitivity Applications:

Select a larger probe diameter.

Ensure the ratio of container diameter to probe diameter is controlled to keep the distance between the plates small.

For low-dielectric media, consider increasing circuit gain or selecting high-sensitivity probe models.

For Space-Constrained Applications:

When the probe diameter is limited, combine it with high-precision detection circuits to enhance sensitivity.

Optimize installation position to avoid interference caused by proximity to the container wall.

For Multi-Medium or Mixed-Medium Applications:

For slurry, mud, or high-gas-content liquids, select probes with corrosion-resistant or anti-adhesion coatings.

In cases requiring high stability, consider adding temperature and density compensation.

Maintenance and Longevity Considerations:

Larger probe diameters improve mechanical strength and wear resistance, but may increase installation complexity, requiring a comprehensive assessment of on-site maintenance needs.

5. Conclusion

Through the analysis of the relationship between probe diameter, capacitance changes, and liquid level height, we conclude:

A larger probe diameter increases sensitivity.

A smaller distance between container and probe diameters results in higher instrument sensitivity.

The dielectric constant of the medium directly affects capacitance change and detection sensitivity.

Practical engineering applications must balance space constraints, medium characteristics, and protection requirements.

For industrial liquid level measurement, understanding the relationship between probe diameter, capacitance changes, and liquid level height not only improves measurement accuracy and response speed but also significantly enhances instrument lifespan and reliability.