1. Traditional View of PID Tuning

In the conventional approach, PID loop tuning is often treated as an isolated single-input, single-output (SISO) problem. The emphasis is placed solely on the controlled process itself.

Once the process model is identified, suitable PID parameters can be directly calculated.

From this perspective, testing and modeling the process are considered the key to PID tuning.

If tuning were only a technical exercise of modeling and parameter calculation, then PID self-tuning should have already been a solved problem.

2. Practical Challenges of PID Self-Tuning

Despite more than 100 years of industrial application, PID controllers still face persistent challenges. Even with simplified PI control (two parameters), problems remain common.

Commercial self-tuning software has not delivered consistently satisfactory results.

To date, more than 1,700 tuning rules have been proposed, most of which are based on simplified tests and are relatively easy to learn.

In reality, the most widely used method in factories is still trial-and-error tuning.

This popularity can be explained:

If the issue truly lies in PID parameters, trial-and-error usually achieves acceptable results as long as engineers know the safe boundaries.

If the problem is not parameter-related, no tuning method will resolve it.

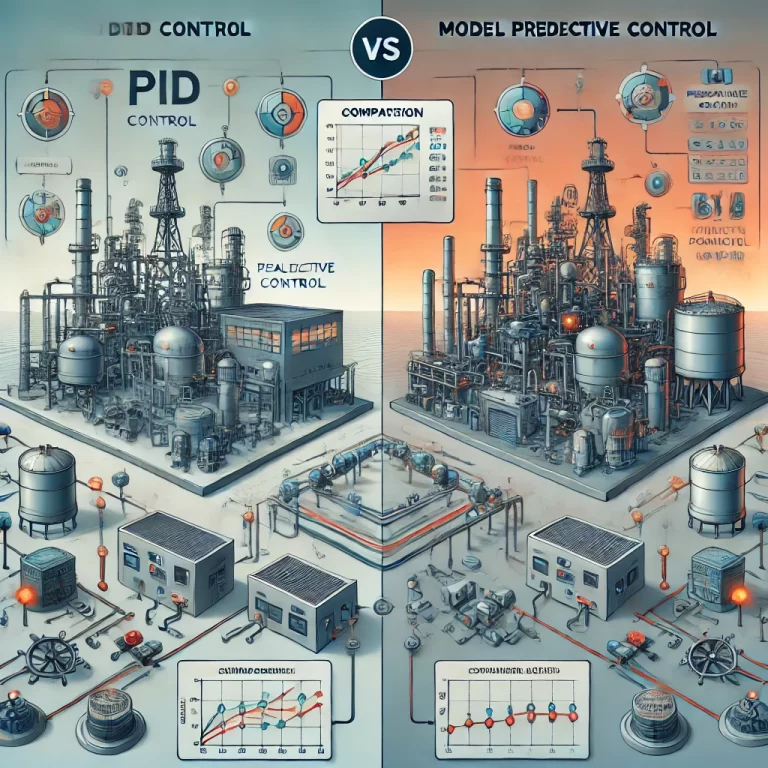

3. Why PID Tuning Is More Than Mathematics

In process industries, more than 97% of control loops are still based on PID algorithms. However, tuning is not merely a mathematical optimization exercise.

PID control is, at its core, a physical intervention in a dynamic system.

In complex plants with multiple manipulated variables influencing each other, tuning becomes an engineering art that requires system awareness.

4. Toward a System Perspective

When multiple PID loops interact within a complex plant, effective tuning requires a broader and more holistic view.

The root cause of poor control performance may lie not only in the PID parameters but also in the configuration, control strategy, or even equipment limitations.

True optimization requires respecting first principles of the system, understanding the physical problem, and then applying PID as one of the tools.

5. Conclusion

Learning PID tuning methods is valuable for understanding the controller’s capabilities and for improving parameter adjustment practices. However, solving control loop problems demands more than parameter optimization.

PID tuning, advanced control, and AI are all tools.

Tools should not be confused with the end goals such as autonomy, black-screen operation, or zero manual intervention.

Only by cultivating a system perspective can engineers apply PID effectively and achieve meaningful control optimization.