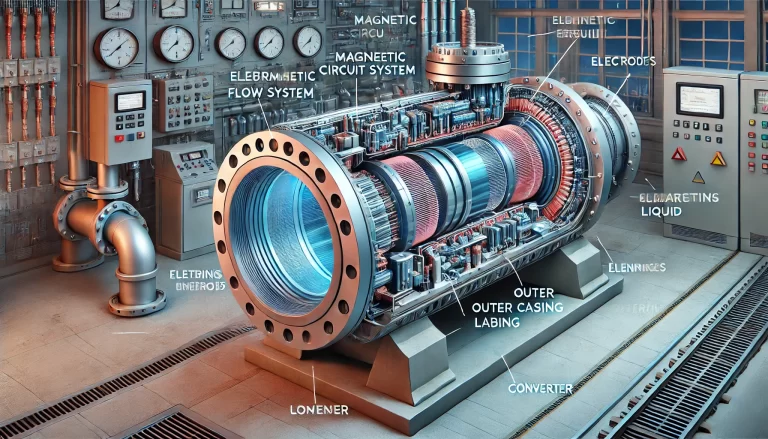

Electromagnetic flowmeters are widely used for measuring the flow of conductive fluids in various industries. However, their performance depends significantly on the properties of the medium being measured. To ensure accurate and reliable operation, specific requirements must be met regarding the conductivity, uniformity, temperature, pressure, and chemical and physical characteristics of the medium. Below is a detailed explanation of these requirements.

1. Conductivity Requirements

Basic Requirement: The medium must have a minimum electrical conductivity of 5 μS/cm. Certain specialized electromagnetic flowmeters can handle lower conductivity mediums, such as partially deionized or high-purity water.

Reason: Electromagnetic flowmeters operate on Faraday’s principle of electromagnetic induction, which requires the medium to generate an induced voltage proportional to its flow rate. Non-conductive mediums (e.g., pure gases, oils) cannot generate this voltage and are therefore unsuitable for measurement.

2. Uniformity of Medium

Basic Requirement: The medium’s conductivity should be consistent and uniform. Uneven compositions, such as layered or poorly mixed mediums, can cause instability in measurement.

Reason: Variations in conductivity lead to fluctuating induced voltage, reducing measurement accuracy.

Best Practices:

Use mixers or homogenizers for mediums with varying properties.

Install the flowmeter in a location with steady and consistent flow.

3. Temperature and Pressure Requirements

Temperature:

Operating Range: The medium’s temperature must fall within the limits of the sensor and lining material, typically -20°C to 120°C, depending on the flowmeter model.

Reason: Excessive temperatures can degrade the lining material (e.g., rubber, PTFE) or damage internal components.

Pressure:

Operating Range: The medium’s pressure should not exceed the flowmeter’s rated capacity, generally 1.6 MPa to 4.0 MPa.

Reason: Overpressure can compromise the structural integrity of the flowmeter.

Best Practices:

Use pressure regulators or relief valves to maintain safe pressure levels.

Insulate or cool pipelines to prevent overheating of the medium.

4. Physical Characteristics of the Medium

Cleanliness:

Requirement: Medium with excessive solid particles or crystallization tendencies may impact flowmeter performance.

Reason: Solid particles can erode the lining or electrodes, while deposits can interfere with signal detection.

Solution:

For abrasive mediums, use linings made of wear-resistant materials such as polyurethane.

Implement regular cleaning schedules to remove buildup.

Flow Conditions:

Requirement: The pipeline must remain fully filled with the medium during operation.

Reason: Air pockets or partially filled pipes lead to measurement errors.

Solution:

Install the flowmeter at low points in the pipeline or in vertical sections with upward flow to ensure full filling.

5. Chemical Properties of the Medium

Corrosiveness:

Requirement: The medium’s chemical properties should not react with the flowmeter’s lining or electrode materials.

Reason: Corrosive mediums can degrade the lining or damage the electrodes, affecting accuracy and lifespan.

Best Practices:

Use PTFE linings for highly corrosive substances (e.g., strong acids and bases).

For less corrosive mediums, rubber or polyurethane linings may suffice.

Scaling:

Requirement: The medium should not cause significant scaling or fouling on the electrodes or lining.

Reason: Scaling reduces signal detection and can alter flowmeter calibration.

Solution:

Choose self-cleaning electrodes or implement regular maintenance.

6. Special Medium Considerations

Liquid-Solid Mixtures:

Requirement: For mediums like slurries or mining pulp, the pipeline must minimize air bubbles and turbulence.

Best Practices:

Install wear-resistant linings.

Use bypass lines or special configurations to accommodate abrasive particles.

Gas-Liquid Mixtures:

Requirement: Mediums with gas bubbles should minimize bubble formation near the flowmeter.

Solution:

Install the flowmeter in locations where bubbles naturally dissipate, such as downstream of degassing equipment.

Conclusion

Electromagnetic flowmeters are precise instruments, but their accuracy and reliability depend on the medium meeting these specific requirements. By carefully evaluating and preparing the medium, users can ensure optimal performance and extend the life of the flowmeter. For complex or specialized applications, consult with technical experts to select the most suitable model and configuration.