Instrument testing facilities can be categorized into two main types: individual unit testing and system-level testing. System testing primarily occurs at sites with remote instruments or centralized control rooms. This document primarily focuses on individual unit testing requirements.

Testing Facility Types

Based on current management practices and the storage locations of instruments upon delivery, the following types of testing facilities are utilized for individual unit testing:

- Testing Room – For pressure and temperature instruments.

- Outdoor Testing Area – For specific instruments, such as float tube level indicators.

- Valve Testing Station – To conduct leakage and strength tests for control valves.

Among these, the testing room is the most critical.

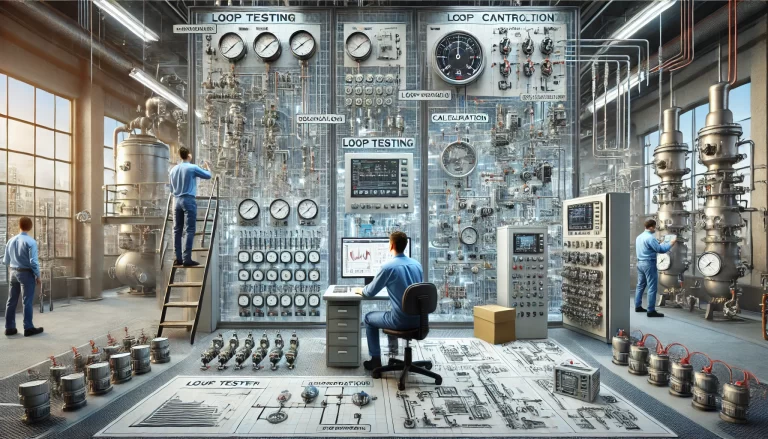

Requirements for the Testing Room

General Location

The setup of a testing room is determined by the overall engineering layout. For smaller facilities, it may be integrated into central control rooms or staff areas, whereas larger setups may require a standalone testing room.

Environmental Standards

According to national norms and industry technical guidelines, the testing room must meet the following requirements to ensure the precision and longevity of instruments:

- Cleanliness: The room must be clean, quiet, and free from electromagnetic interference or vibrations.

- Lighting: Sufficient natural or artificial light is essential.

- Temperature and Humidity: The room temperature should remain between 10°C and 35°C, with relative humidity below 85%.

- Water Supply: Facilities for running water and drainage are required.

- Stable Power Supply: Voltage fluctuations should not exceed ±10% for AC power and DC power above 60V. For DC power below 60V, fluctuations should not exceed ±5%.

- Compressed Air Supply: The air source should be clean and dry, with a dew point at least 10°C below the lowest ambient temperature. Pressure stability is mandatory.

Additional Considerations

Location:

- The room should be positioned near the supply storage area to minimize transportation damage.

- Equipment awaiting inspection should be categorized into designated areas: pending inspection, approved, and rejected zones.

Room Zoning:

- Separate sections should be established for different inspection activities, such as high-temperature testing, low-temperature testing, and calibration of pressure gauges and transmitters.

Room Management:

- Cleanliness: The room should be cleaned regularly, and personnel entering the room must wear appropriate footwear and clothing.

- Power Stability: High-precision automatic voltage regulators must be used to mitigate fluctuations.

- Environmental Control: Air conditioning units should maintain a stable temperature of 23°C ± 5°C.

- Equipment: Advanced computers, laser printers, and testing devices should be installed for efficient data recording.

Outdoor Testing Area

Purpose and Instruments

The outdoor testing area primarily supports liquid level instruments requiring additional height or spatial arrangements, such as float-type level transmitters.

Facility Requirements

- Instrument Support: Secure instrument stands to handle tall and heavy devices.

- Water Supply: A clean water source is necessary for wet calibration when using a medium with a lower density than water.

- Safety Features: Pulley systems and auxiliary platforms to minimize manual handling risks.

Improvements to Traditional Practices

- Pulley Systems: Replace manual lifting with pulleys to reduce friction and effort.

- Automated Adjustments: Utilize communicators for remote parameter configuration to avoid unsafe high-altitude operations.

- Water Supply: Integrate ground-level water supply systems for safer and more efficient calibration.

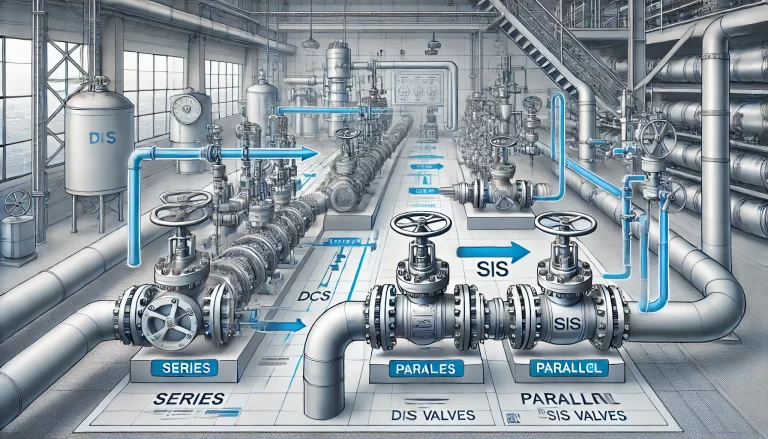

Valve Testing Station

Key Functions

Valve testing stations are essential for conducting leakage and strength tests for control valves, which are often too large or heavy for standard storage rooms.

Requirements

- Air Source: Ensure an adequate supply of compressed air at 0.5 MPa, sourced either from nitrogen tanks (for low usage) or small compressors (for high usage).

- Air Quality: Incorporate filtration and drying systems to meet the cleanliness and dryness standards required for instrument calibration.

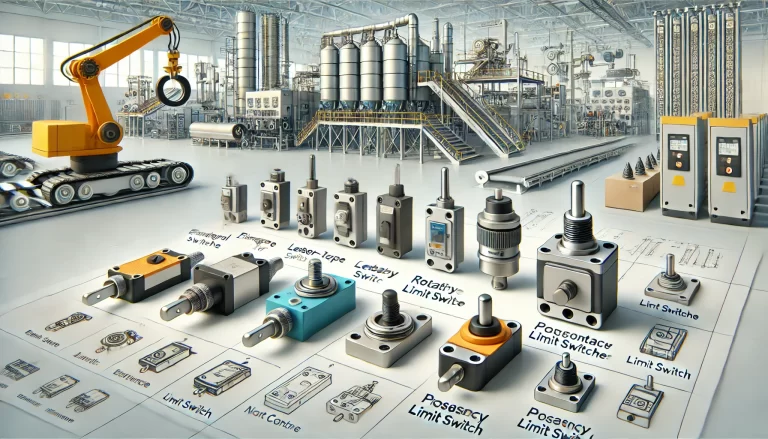

Liquid Level Switch Testing

Switch Types

- Float-Type Switches: Utilize magnetic coupling to activate reed switches based on liquid levels. Key checks include:

- Free movement of the float.

- Sufficient magnetic force for reliable activation.

- Good reed switch contact.

- Buoyancy-Type Switches: These require quantitative checks and calibration to account for differences between the testing and operating mediums.

Testing Process

To avoid misalignments:

- Introduce liquid slowly to ensure stable float movement.

- Use calibrated marks to monitor activation points and correct any deviations from the expected range.

Software and Procedural Standards

Standard Documentation:

- Develop clear regulations, such as “Measurement Tool Management Guidelines” and “Safety Management Guidelines for Testing Rooms.”

- Establish a “Calibration Tool Management Log” to track the status of all devices.

Certification:

- Ensure personnel are certified and that certifications remain valid.

- Maintain a record of instrument use, including detailed logs for borrowed equipment.

Inspection Procedures:

- Instruments must pass pre-testing inspections based on project classifications.

- Only approved facilities may conduct calibration tests.

Conclusion

This document outlines the essential requirements for establishing and maintaining instrument testing facilities. Adherence to these guidelines ensures the accuracy, safety, and reliability of instrument testing and calibration processes. These improvements not only align with technical standards but also enhance operational efficiency and safety.