Root Causes and Practical Protection Measures

1. Introduction

In chemical and process industries, the reliable operation of field instruments is critical to production safety and efficiency. During the rainy and thunderstorm season, instruments are particularly vulnerable to failures caused by moisture ingress, water accumulation, and lightning strikes.

This document provides a structured guide to rainproofing and lightning protection measures for instrumentation systems, supported by practical methods, standards, and case-based insights.

2. Rainproof Measures

2.1 Instrument Room Sealing and Waterproofing

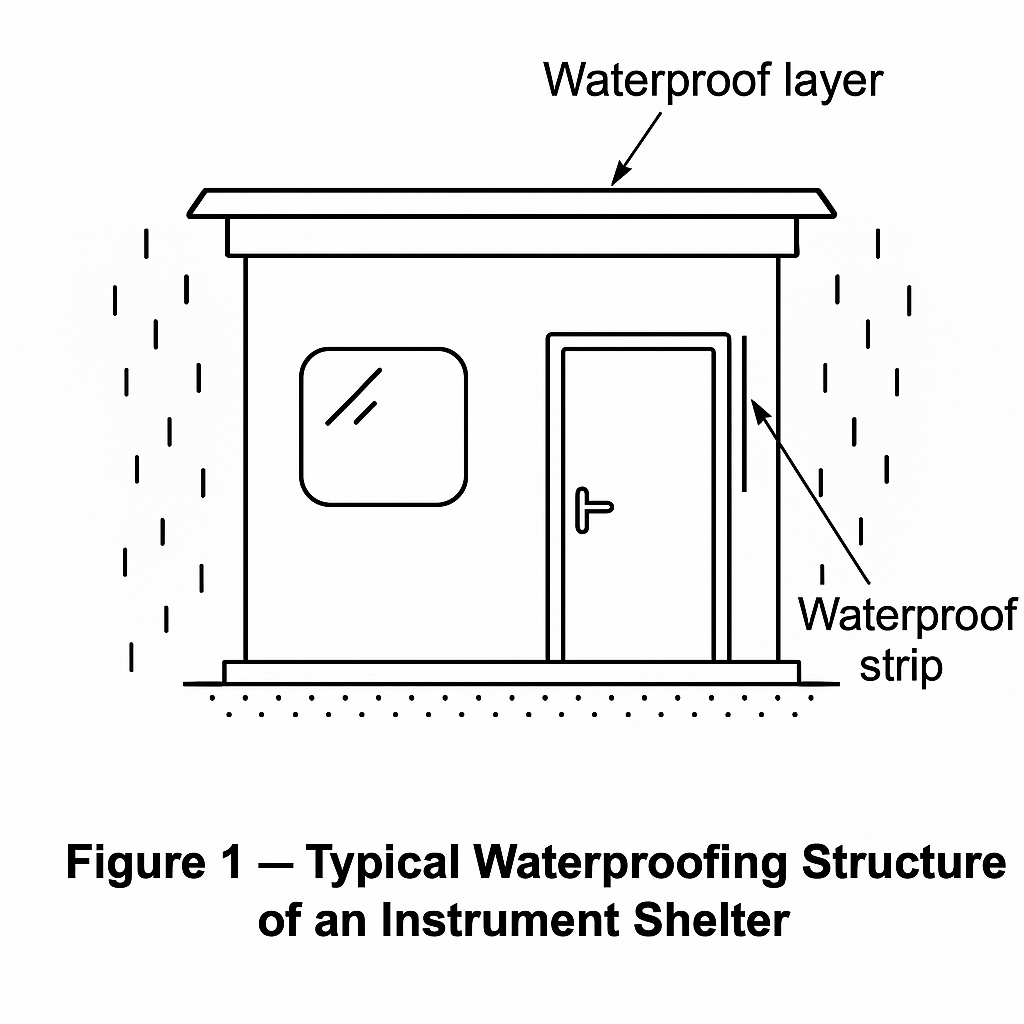

Install waterproof strips on doors and windows to ensure tight closure.

Apply a waterproof layer on the instrument room roof to prevent seepage.

For outdoor instruments, use waterproof enclosures or cabinets.

2.2 Drainage System

Ensure the surroundings of the instrument room are equipped with drainage channels.

Inspect pipelines regularly to avoid blockage.

In low-lying areas, elevate the floor or construct water barriers to prevent backflow.

2.3 Instrument Waterproofing

Conduct periodic inspections of outdoor instruments to verify casing integrity.

Seal cable entries to prevent rainwater ingress.

Replace cracked or aged sealing gaskets.

3. Lightning Protection Measures

3.1 Grounding System

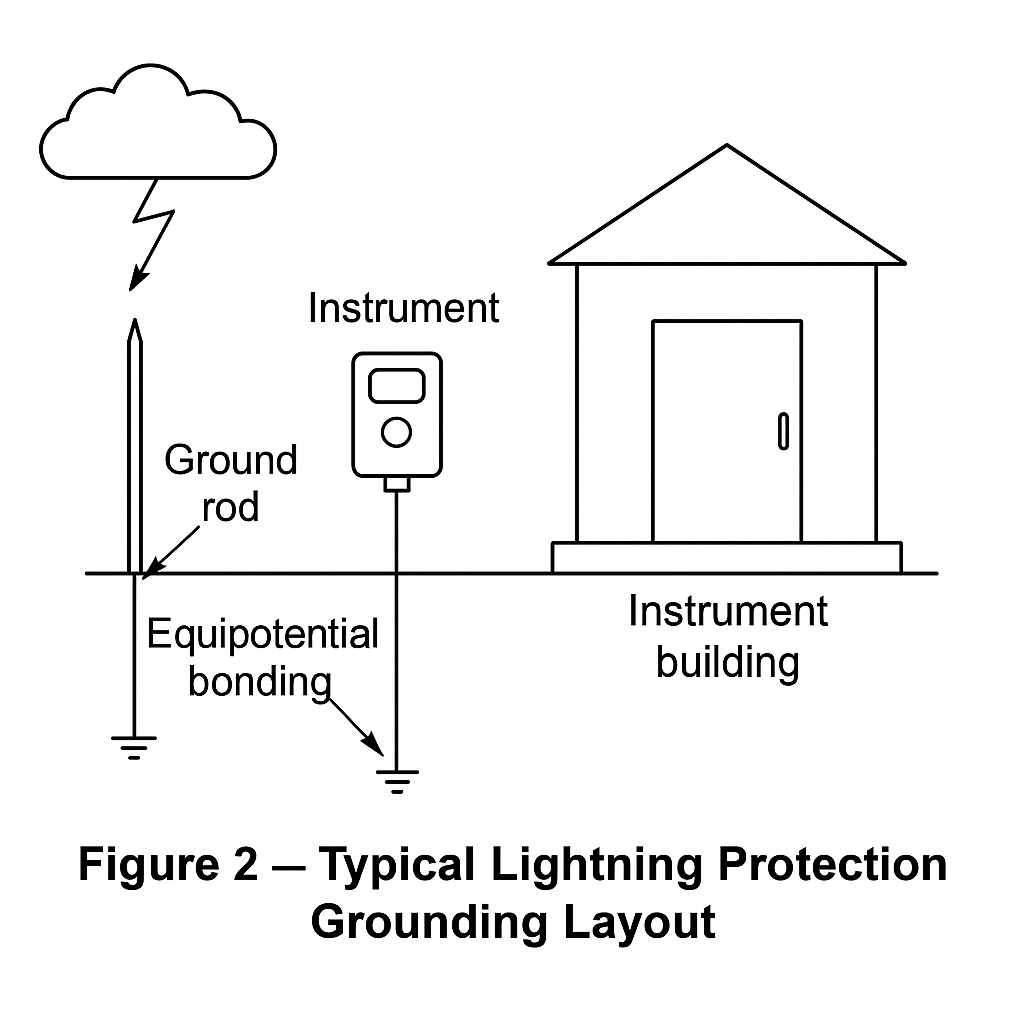

Ensure instruments have a reliable grounding network.

The grounding resistance should generally be ≤ 10 Ω (as per GB 50057 / IEC 62305).

Critical instruments should have independent grounding to reduce backflash risks.

3.2 Surge Protection Devices (SPD)

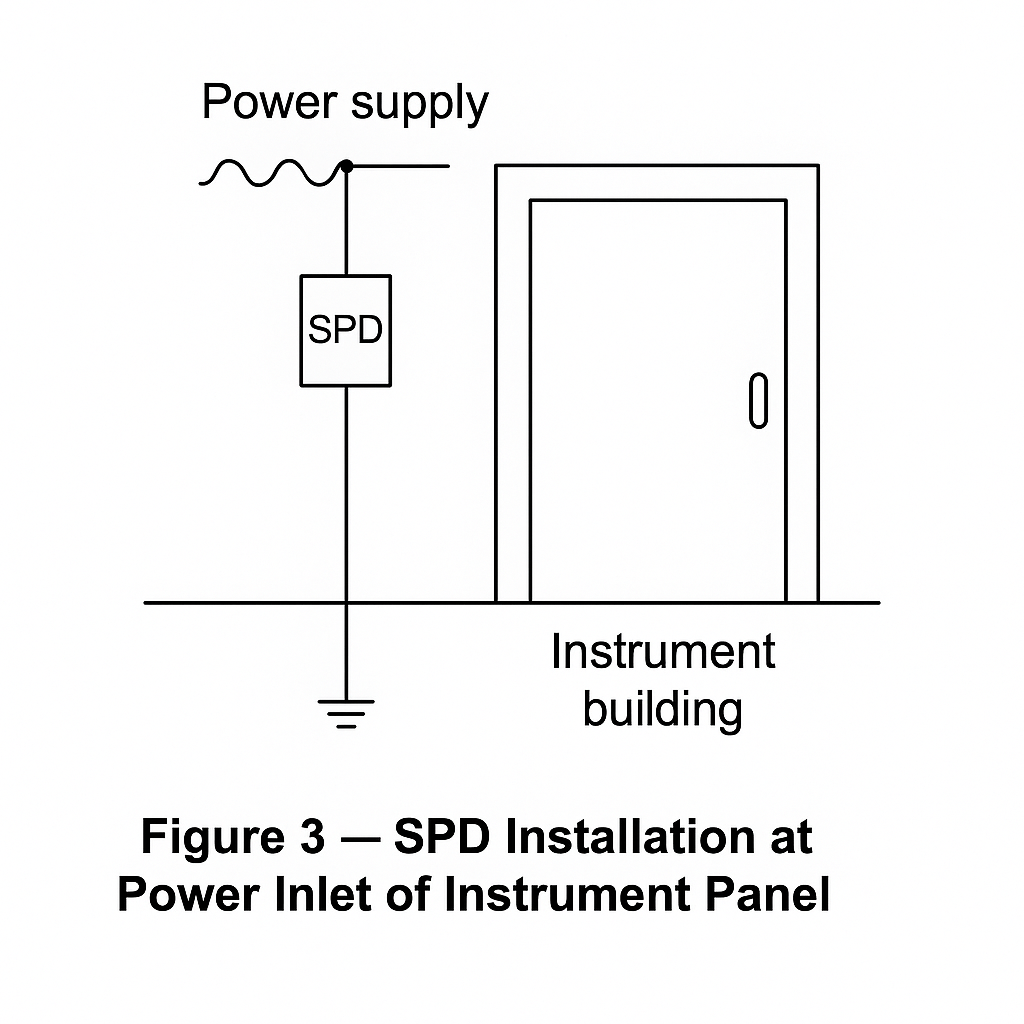

Install SPDs at instrument power supply inlets.

Select SPD models according to rated voltage and protection class.

Ensure SPD replacement and inspection after major lightning events.

3.3 Equipotential Bonding

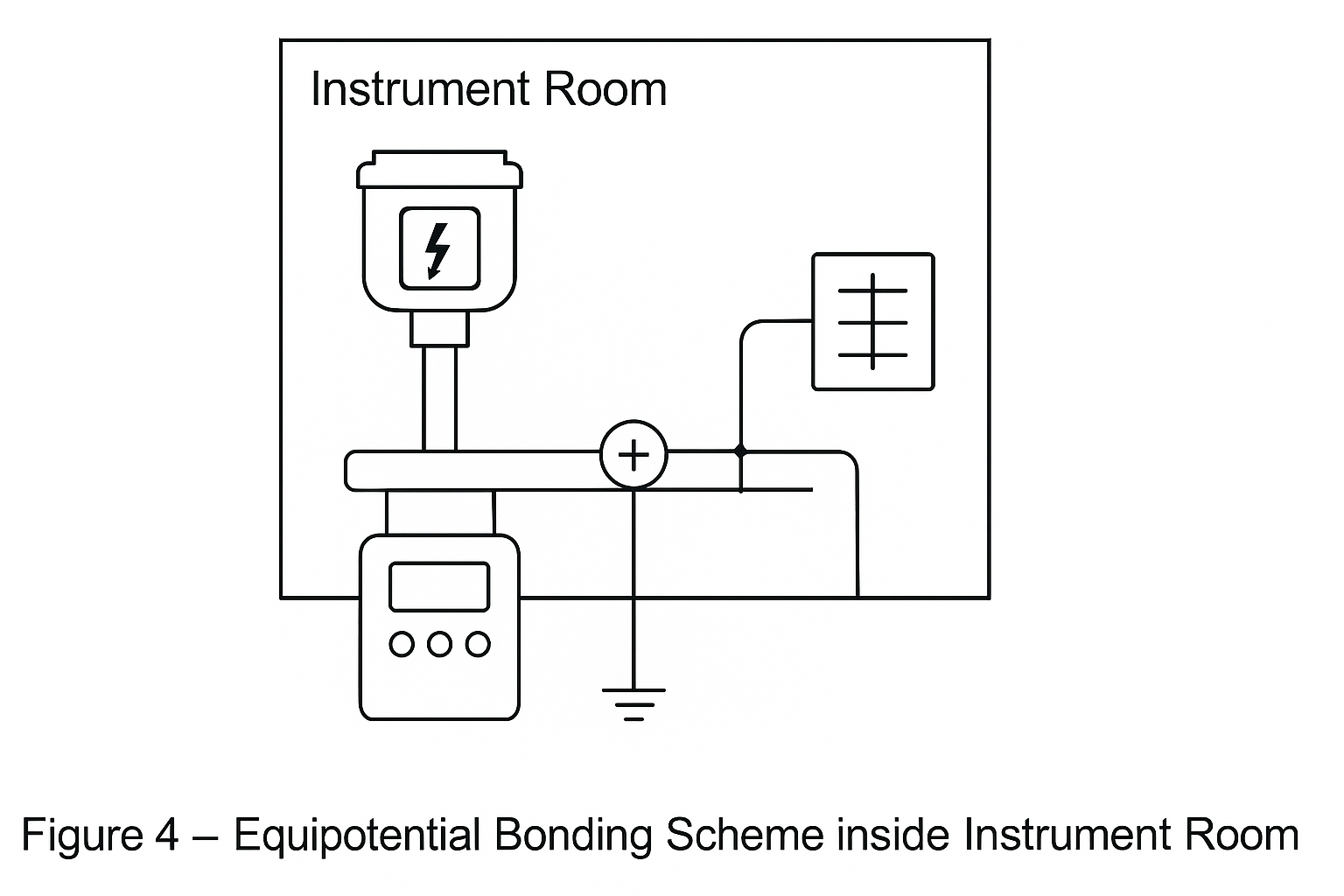

Connect metallic structures, pipelines, and instrument racks to a common equipotential system.

Prevent spark discharge caused by potential differences.

Use reliable copper/aluminum conductors with secure connections.

3.4 Shielding

Use metallic cable trays, conduits, or grounded shielding enclosures.

Apply shielding to sensitive electronic devices to minimize lightning electromagnetic pulse (LEMP) interference.

Ensure shielding continuity and grounding.

3.5 Inspection & Maintenance

Perform regular testing of grounding resistance and SPD performance.

Keep inspection records and rectify defects immediately.

Schedule maintenance before thunderstorm season.

4. Reference Table: Lightning Protection Implementation

Table 1 — Lightning Protection Categories and Key Implementation Points

| Measure | Implementation Requirement | Reference Standard |

|---|---|---|

| Grounding | Resistance ≤10 Ω; independent grounding for key units | GB 50057, IEC 62305 |

| SPD Installation | Class I & II surge protectors for power circuits | IEC 61643 |

| Equipotential Bonding | Metallic pipes, racks, structures connected | GB/T 14287 |

| Shielding | Cable trays, metallic conduits, shielded housings | IEC 61000 |

| Routine Maintenance | Annual resistance test, post-storm SPD inspection | Company SOP / IEC 62305 |

5. Case Example (Illustrative)

Issue: A radar level transmitter failed after a thunderstorm.

Root Cause: Grounding resistance > 50 Ω and SPD not installed.

Solution: Rebuilt independent grounding system (≤10 Ω), added Class II SPD, established routine inspection.

Outcome: No further failures in subsequent rainy seasons.

6. Conclusion

Rainproofing and lightning protection of instruments require systematic design, routine maintenance, and compliance with standards.

By strengthening sealing, drainage, grounding, SPD installation, equipotential bonding, and shielding, industries can greatly enhance the reliability of instrumentation and ensure stable operation during rainy and thunderstorm seasons.