In industries like chemical storage tanks, LNG storage and transportation, and heating systems, level measurement is crucial for ensuring both production safety and process stability. However, complex operating conditions, such as high temperatures, pressures, and strong corrosion, often cause traditional level transmitters, like float and differential pressure devices, to fail. Radar level transmitters, with their non-contact measurement characteristics, have become essential tools in such environments.

In this article, we provide a comprehensive breakdown of radar level transmitters, from their principles and operational limits to the effects of media characteristics and installation details.

1. What is a Radar Level Transmitter?

A radar level transmitter is a non-contact level measurement instrument based on microwave reflection principles. It emits high-frequency microwaves through an antenna towards the measured medium, then captures the reflected signal to calculate the liquid level inside a container. This makes it the “go-to” choice for monitoring levels in industrial storage tanks, reactors, and other vessels.

2. Measurement Principle

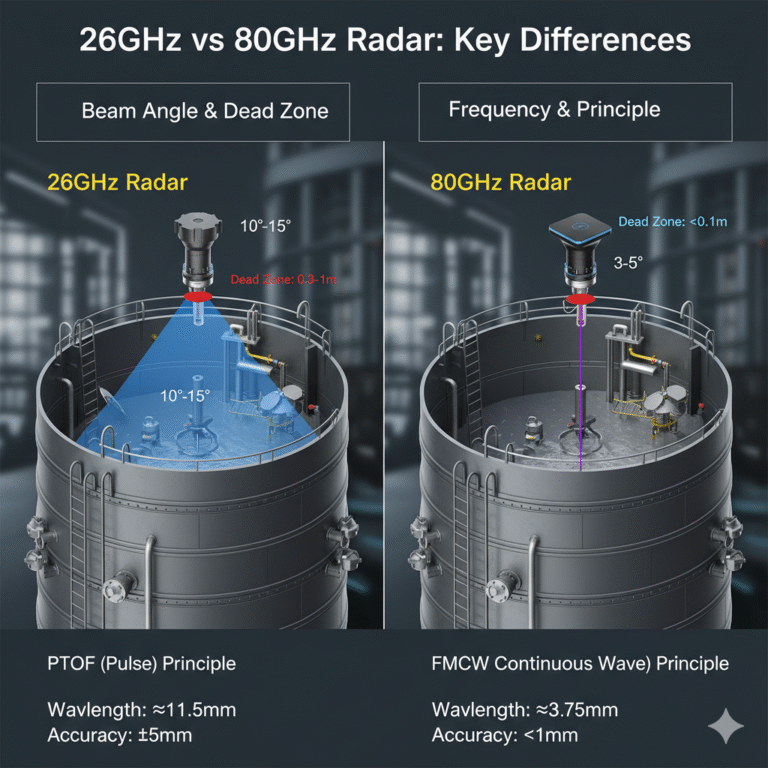

There are two main techniques used in radar level transmitters:

Time-of-Flight Method (Pulse Radar)

In this method, a microwave pulse with a fixed frequency is emitted. The time taken for the pulse to travel to the surface and return is measured, and the level is calculated using the formula:= speed of light (approx. 300,000 km/s)

= vertical distance from the probe to the liquid level (m)

= time for microwave to travel to and from the liquid level (s)

This method is simple and widely used in general industrial applications.Frequency Modulated Continuous Wave (FMCW) Radar

This method emits a continuous wave with a frequency that linearly changes over time. By measuring the frequency difference between the emitted and reflected signals, the level is calculated. This method offers higher accuracy (error as low as 0.1mm) and is typically used in commercial metering applications, such as LNG tank measurements for trade settlements.

3. Temperature and Pressure Effects

One common misconception is that radar level transmitters are unaffected by temperature and pressure changes. While it’s true that microwave propagation itself is not significantly influenced by these factors, the components of the transmitter do have temperature and pressure limits.

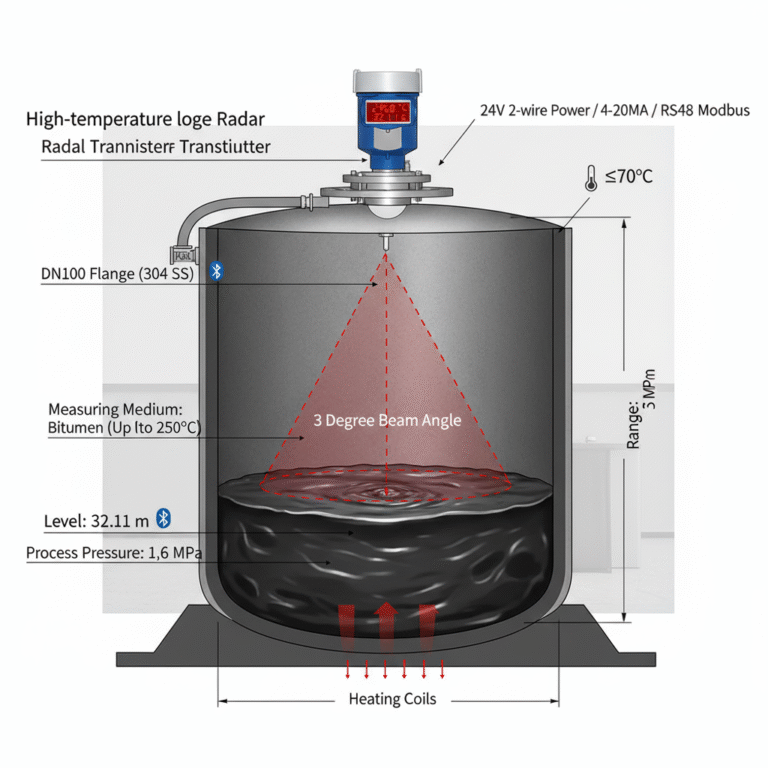

Temperature Impact

The speed of microwaves through a medium is virtually unaffected by temperature changes. However, the components like the sensor and antenna have a maximum temperature tolerance (typically between -40°C and 300°C depending on the model). Excessive temperature can cause component aging or signal distortion.Solution:

To measure high-temperature media, forced air or water cooling should be applied to the antenna, or the antenna should be placed at a distance from the highest liquid level to avoid direct exposure to extreme temperatures.Pressure Impact

While the propagation of microwaves is not impacted by air density (whether under vacuum, atmospheric, or high pressure), the structural integrity of the instrument is. If the pressure in the container exceeds the transmitter’s rated pressure tolerance, sealing may fail, leading to measurement errors.

4. Media Characteristics

The interaction between microwaves and the medium being measured is critical to the radar level transmitter’s performance. Key characteristics of the medium include:

Relative Permittivity (Dielectric Constant)

This is the most important factor affecting microwave reflection. A higher dielectric constant means better reflection, while a lower value causes more refraction or absorption of microwaves, weakening the signal. Typically, radar level transmitters require a dielectric constant of at least 1.5–2, although some newer models can measure lower dielectric constants, such as in liquid hydrocarbons (e.g., gasoline or diesel).Liquid Turbulence and Foam

Turbulent liquid surfaces scatter microwaves, and foam absorbs microwave energy. Both effects can reduce the strength of the reflected signal. The effect is negligible in smaller measurement ranges, but for longer measurement paths, careful evaluation of operational conditions is necessary.Corrosive and Crystallizing Media

Corrosive or crystallizing substances can damage the probe. To mitigate this, separate flanged structures with PTFE (polytetrafluoroethylene) windows are used, but it’s important to note that PTFE can only tolerate temperatures up to 200°C. To prevent damage, the flange should be positioned 100–800mm away from the highest liquid level.

5. Installation Considerations

The effectiveness of a radar level transmitter depends not only on its specifications but also on proper installation. Here are four critical factors to consider:

Avoid Feed Inlets and Vortices

The feed inlet can generate strong false echoes, which can overwhelm the actual liquid level signal. Vortices can also scatter microwaves.Keep Away from Agitators

Agitators can create false echoes, and their blades can interfere with signal reception, especially when the medium has a low dielectric constant or when measuring low liquid levels.Maintain Safety Distance for Corrosive or Crystallizing Media

For corrosive or crystallizing media, maintain a safe distance (100–800mm) from the highest liquid level to avoid damage to the flange or probe.Ensure the Antenna is Vertically Aligned

Misalignment can cause signal deviation and result in poor measurement accuracy.

6. Advantages of Radar Level Transmitters

Compared to traditional level transmitters, radar level devices offer several key advantages:

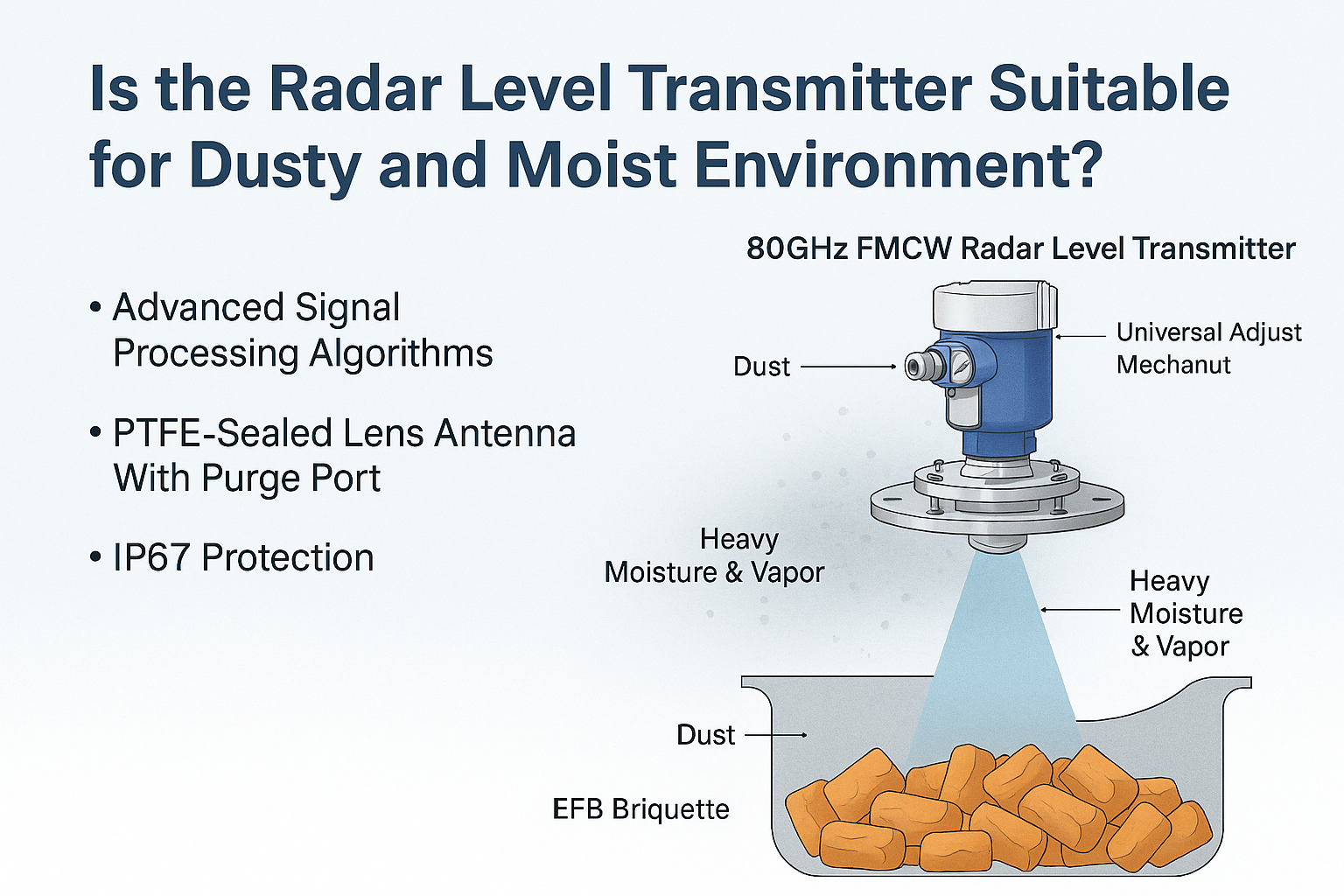

Non-contact Measurement

No moving parts or physical contact with the medium, making them suitable for measuring high-viscosity, corrosive, toxic, or sanitary fluids. They are also unaffected by vapors, mist, or dust.No Measurement Blind Spot & High Accuracy

Unlike float-based devices, radar transmitters have no “dead zone,” and the measurement accuracy can reach up to 1mm (special models can achieve 0.1mm). This makes them ideal for commercial metering purposes.Strong Adaptability to Harsh Environments

Radar transmitters are suitable for a wide range of temperatures (-40°C to 300°C) and pressures, from vacuum conditions to high-pressure environments, as long as the components are within the tolerance limits.

7. Conclusion

When selecting a radar level transmitter, focus on these three key parameters:

The relative permittivity of the medium (ensure it meets the transmitter’s minimum requirements).

The temperature and pressure limits of the operating environment (ensure they match the transmitter’s component tolerances).

The installation environment (avoid interference from sources like feed inlets or agitators).

If you face complex level measurement challenges, we recommend contacting a professional manufacturer for customized solutions to avoid measurement failures due to mismatched parameters.