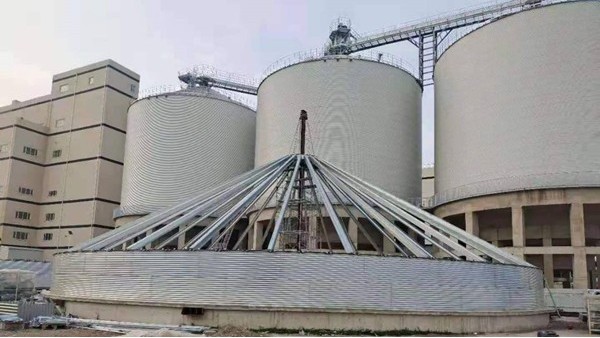

Radar level meters are widely used for level measurement in small silos in the baking industry. This paper will introduce the characteristics of small silos for baking ingredients and provide two actual measurement cases to demonstrate the application of radar level meters in this area.

Baking ingredient silos are characterized by the following features: Small capacity: Compared to large warehouses, baking ingredient silos usually have a smaller capacity.

As the baking process requires more precise control of the ingredients, the smaller capacity design is more conducive to control and management.

Liquid ingredients: During the baking process, some ingredients are used in liquid form.

These liquid ingredients may have different viscosity and fluidity, which puts high demands on the level measurement equipment. Temperature variations: During the baking process, the temperature inside the small silo may change.

Therefore, level-measuring devices need to be able to adapt to different temperature conditions for accurate measurement. Rapid response: The mixing of baking ingredients needs to be based on real-time demand, so level measurement equipment needs to have the ability to respond quickly in order to adjust the ingredients and process them in a timely manner.

Below are two actual measurement cases demonstrating the application of radar level meters in the level measurement of small silos for baking ingredients.

Case 1: Flour is one of the commonly used ingredients in the baking industry. Flour is often stored in liquid form in small silos, where accurate level measurement is critical.

Traditional level measurement methods such as float and differential pressure level meters are not able to meet the requirements for accurate control of the baking process.

A radar level meter is a non-contact liquid level measurement device, which measures the liquid level by transmitting and receiving high-frequency electromagnetic waves.

It can accurately measure the level change of flour in the small silo, and timely feedback data to the control system.

This real-time monitoring and feedback help operators make timely adjustments and controls as needed to ensure the accuracy and consistency of ingredients.

Case 2: Yeast liquid is one of the important ingredients in baking processes such as bread and cakes. Yeast liquid is usually stored in small silos in liquid form and is somewhat viscous.

Traditional level measurement methods are often affected by viscous liquids, making it difficult to provide stable and accurate level measurement data.

The radar level meter adopts the transmission and reception of high-frequency electromagnetic waves, which is characterized by non-contact measurement and can accurately measure the level of yeast liquid.

Moreover, the radar level meter is not affected by parameters such as viscosity, density, and fluidity of the liquid, so it has good versatility and is suitable for all kinds of liquid dosage measurements.

Characteristics of small silos include small capacity, liquid dosage, temperature variation, and fast response. These characteristics also necessitate level measurement devices that are accurate, stable, fast responding, and versatile.

Two real-world measurement examples demonstrate the use of radar level meters in applications such as flour storage and yeast liquid storage.

It can accurately measure liquid level changes and provide timely feedback data to help operators quickly respond and adjust the processing of baking ingredients, thus improving production and work efficiency.