Level measurement of feed storage towers in the livestock industry is critical to ensuring animal feeding efficiency and cost control. However, this process is full of challenges due to the influence of multiple factors.

This article will analyze in detail the difficulties in level measurement of feed storage towers, and use a practical case to illustrate how radar level meters can effectively solve these problems.

The main difficulties faced in measuring the material level of feed storage towers include the complexity of the internal environment of the feed tower, the unevenness of the material level, and dust problems. First, the environment inside the silo may become unstable due to changes in temperature and humidity, which will affect the accuracy of the sensor.

Secondly, feed may accumulate unevenly during storage, causing errors in material level readings. Finally, the generation of feed dust may interfere with the operation of traditional sensors and reduce measurement accuracy.

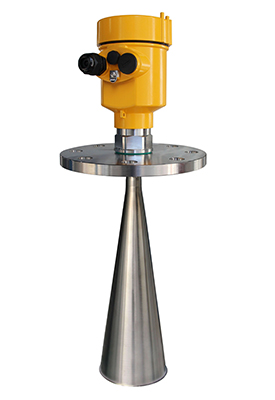

The radar level meter uses the principle of microwave signal reflection to measure the material level by sending microwave pulses and receiving their echoes.

This technology is not affected by dust, steam or high humidity and can work reliably in harsh environments. Taking a large livestock farm as an example, the farm uses an advanced radar level meter to monitor the material level of its feed storage tower.

Before implementation, the farm faced serious feed waste and difficulty in inventory management. Traditional weight sensors often give inaccurate readings due to interference from dust, resulting in insufficient or oversupply of feed. After installing the radar level gauge, the situation improved significantly.

First of all, the equipment can penetrate the dust in the material tower and accurately measure the material level. Secondly, even if the feed is unevenly accumulated, the radar wave can cover the entire feed surface, ensuring the comprehensiveness and accuracy of the measurement results.

In addition, the data from the radar level gauge can be transmitted to the central control system in real time through the wireless network, allowing managers to monitor material level changes at any time and adjust the feed supply plan in a timely manner.

The application of radar level gauges in feed storage tower level measurement not only solves the environmental adaptability and accuracy problems faced by traditional measurement methods, but also brings more efficient management to the animal husbandry through real-time monitoring and data analysis. model.

With the continuous advancement of technology, radar level meters are expected to be widely used in more fields in the future, providing more accurate and reliable solutions for material storage and management in various industries.