Introduction

Radar level meters are advanced instruments that have become integral to modern industrial applications due to their high precision, reliability, and adaptability. One particularly significant use case is their application in beer filling machines, where they ensure accurate measurement of liquid levels in finished product tanks. This article explores the working principles, advantages, and the essential role radar level meters play in maintaining efficiency and quality in beer production.

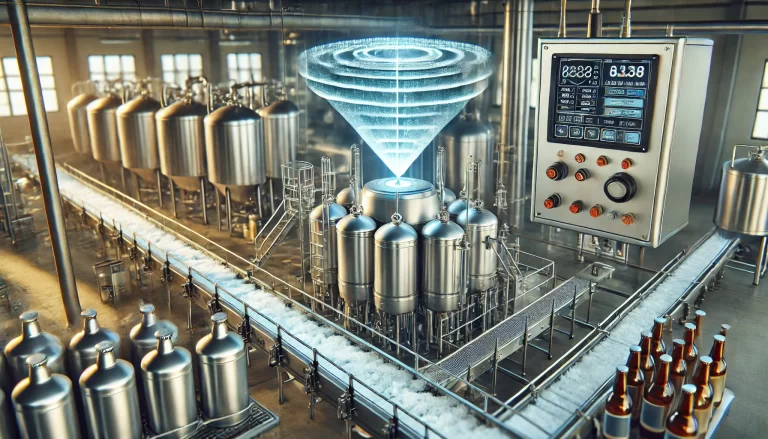

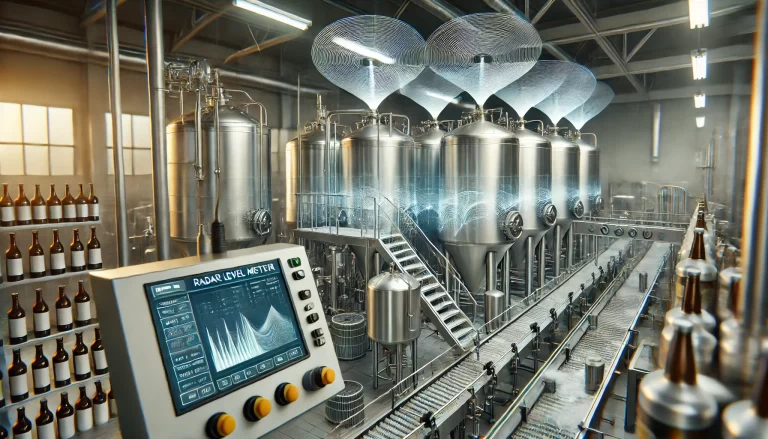

Working Principle of Radar Level Meters

A radar level meter functions by emitting microwave signals, which reflect off the surface of the liquid being measured. By calculating the time it takes for the signal to return, the system determines the distance to the liquid’s surface, allowing for precise level measurement. Unlike traditional ultrasonic or mechanical level meters, radar-based instruments excel in environments with interference and are suitable across a wide range of operating conditions.

Key Advantages for Beer Filling Machines

1. High Precision in Liquid Measurement

Radar meters deliver highly accurate readings, unaffected by variables such as temperature, pressure, or humidity. In the beer production environment, where precise liquid levels are essential to maintain standard bottle volumes, this accuracy is indispensable. It ensures each bottle meets the desired specifications, reducing wastage and maintaining consistency across the product line.

2. Stability and Long-term Reliability

In beer production, liquid levels need to be monitored continuously over extended periods. Radar level meters are designed to operate reliably over long durations with minimal maintenance. Their non-mechanical sensors reduce the likelihood of wear and tear, contributing to a lower maintenance burden and ensuring stable operation. This durability aligns well with the continuous nature of beer manufacturing processes.

3. Resilience in Challenging Environments

Beer production involves environments with foam and steam, which can interfere with traditional measurement tools. Radar meters, however, can penetrate foam to detect the true liquid level without being affected by the foam layer. Their strong signal penetration also ensures that steam within tanks does not obstruct accurate measurements, making them well-suited for beer filling machines.

4. Non-contact Measurement for Food Safety

A major advantage of radar meters is their non-contact measurement capability. This means the instrument does not physically interact with the liquid, minimizing contamination risks. This feature is especially important in the food and beverage industry, where hygiene standards are paramount. The absence of contact also reduces the influence of liquid properties such as viscosity or corrosiveness on the measurement.

Integration with Automation Systems

In modern beer production facilities, radar level meters are often integrated into automated control systems. This integration enables real-time data transmission and remote monitoring. Operators can track liquid levels in each tank from the control room, facilitating proactive adjustments to the filling process. Such intelligent monitoring not only enhances production efficiency but also ensures consistent product quality.

Conclusion

Radar level meters have become indispensable tools in the beer production industry. Their high precision, durability, adaptability, and non-contact measurement capabilities make them ideal for ensuring accurate liquid measurement in beer filling machines. By combining advanced technology with seamless integration into automated control systems, radar meters enhance operational efficiency and help maintain the highest product quality standards. As beer production continues to evolve, radar level measurement technology will remain at the forefront, supporting the industry’s drive for precision and reliability.