When operating a three-valve manifold for differential pressure instruments, two principles must always be observed:

Never allow the condensate or sealing liquid in the impulse lines to drain.

Never expose the measuring element (diaphragm or bellows) to sudden pressure or temperature stress.

To achieve this, the three-valve manifold must be operated in the correct sequence during commissioning and shutdown.

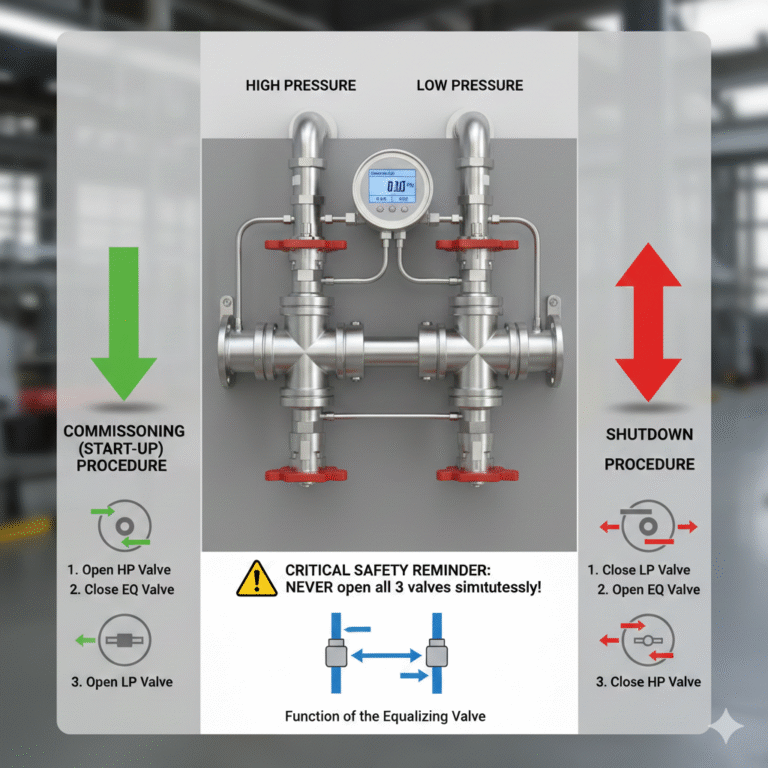

1. Commissioning (Start-up) Procedure

The proper start-up sequence is:

Open the high-pressure valve.

Close the equalizing valve.

Open the low-pressure valve.

This sequence ensures that the transmitter receives differential pressure gradually and symmetrically, avoiding sudden pressure shocks.

2. Shutdown Procedure

The shutdown sequence is the reverse of commissioning:

Close the low-pressure valve.

Open the equalizing valve.

Close the high-pressure valve.

This safely relieves differential pressure from the transmitter before isolating it from the process.

3. Critical Safety Reminder

For steam flowmeters and level transmitters with negative elevation (wet-leg), the high-pressure valve, low-pressure valve, and equalizing valve must never be open simultaneously, even for a very short moment.

If all three valves are open:

Condensate in the low-pressure side (or the sealing liquid in the wet-leg chamber) may drain away.

This will cause measurement errors, signal drift, or even force the instrument out of service.

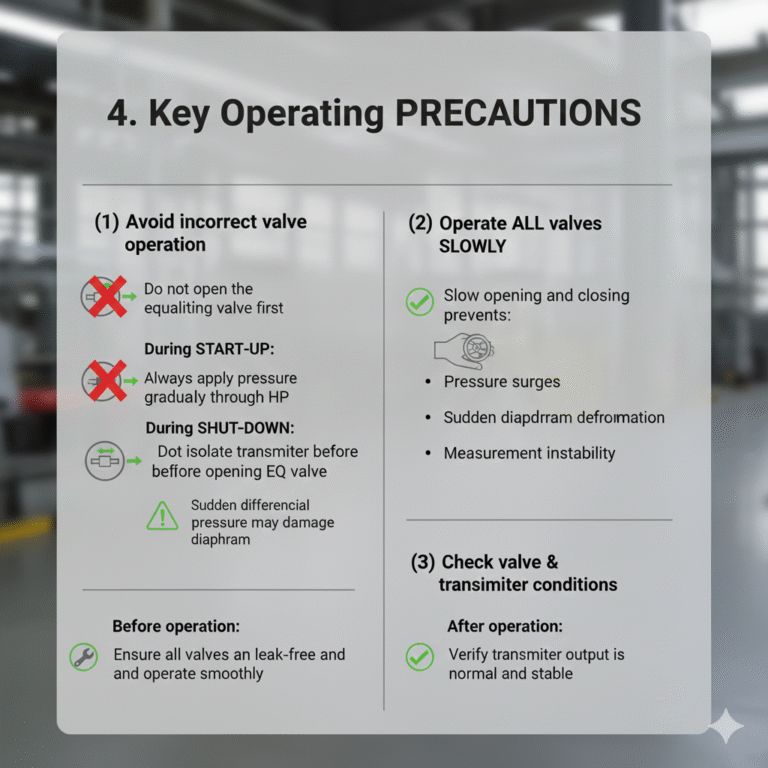

4. Key Operating Precautions

(1) Avoid incorrect valve operation

During start-up:

Do not open the equalizing valve first.

Always apply pressure to the transmitter gradually through the high-pressure side.

During shutdown:

Do not isolate the transmitter before opening the equalizing valve.

Sudden differential pressure may damage the diaphragm.

(2) Operate all valves slowly

Slow opening and closing prevents:

Pressure surges

Sudden diaphragm deformation

Measurement instability

(3) Check the valve and transmitter conditions

Before operation:

Ensure all valves are leak-free and operate smoothly.

After operation:Verify that the transmitter output returns to a normal and stable reading.

5. Function of the Equalizing Valve

The equalizing valve connects the high-pressure and low-pressure sides.

Its purpose is to:

Equalize pressure on both sides of the transmitter

Maintain a differential pressure of zero when required

Protect the transmitter diaphragm from sudden differential loading

If the process medium is viscous or dirty, equalization may not work perfectly and should be checked more carefully.