The measurement of flow rate, temperature, pressure, level, etc. is the same as thermal measurement, which is one of the important measurement parameters in industrial and agricultural production process control. Flow measurement has an inseparable relationship with people’s daily life. Therefore, as a flow meter for flow measurement, it has a wide range of applications. Its applications are in steel, metallurgy, water supply, drainage, petroleum, chemical, food, medical, environmental protection, aviation, navigation, aerospace, agricultural irrigation, and other sectors.

However, the detection of fluid flow is much more difficult than the detection of other parameters such as temperature and pressure. The reason is that the flow parameter is affected by the working conditions of the conveying fluid, such as pressure, temperature, flow state, fluid type, shape, and other parameters. To achieve the purpose of correct measurement, different measuring instruments and different compensation measures must be used.

This means that there are many types and varieties of flow meters. For example, considering the measurement of different fluid states, there are different flow meters for gas, water, steam, and oil. For the same liquid measurement, the flowmeter used is also different.

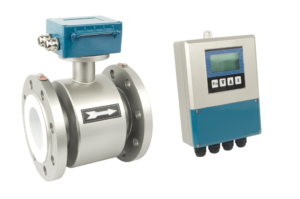

For example, the use of an electromagnetic flowmeter can measure the flow of conductive liquids, but with the different conductivity properties of the fluid, the flow measurement of liquid metal requires the use of a DC magnetic field or low-frequency excitation electromagnetic flowmeter; the measurement of low-conductivity fluids requires a capacitive electromagnetic flowmeter, etc.

Therefore, the research and use of flow meters are much more difficult than other measuring instruments. Only by combining the specific measurement fluid object and the measurement purpose, and selecting the appropriate flowmeter, can the effective flow measurement be carried out in a reasonable, economical, reliable, and accurate manner.

As far as the purpose and significance of flow measurement are concerned, one of the purposes of using flowmeter measurement is to provide managers or control systems with accurate values of flow parameters in the production process, so as to make reasonable judgments and adjustments to achieve excellent control and improve product quality and output. Arms such as the ratio of chemical production raw materials, the dosing of water and sewage treatment, high-pressure water injection for oil extraction, steel blast furnace leak detection, continuous casting and rolling, etc., are effective means to improve labor productivity, improve product quality, and reduce workers. Effective measures for labor intensity and improving workers’ working conditions.

At the same time, it provides enterprise managers with scientific and reliable data such as reducing costs, reducing energy consumption, and increasing the service life of equipment during the production process. Therefore, the application of flow meters to measure flow is a powerful measure to improve the level of scientific management of enterprises and maximize economic and social benefits. This purpose of flow measurement is called “monitoring purpose”. Another purpose of flow measurement is to provide a reasonable trade settlement value for the supply and demand parties to measure and transfer the total amount of trade fluid based on economic benefits.

The flowmeter is used to continuously accumulate the total value for a period of time to provide a scientific and reliable total volume or total mass of the fluid for trade settlement and total volume control. We call this “metering purpose”. Oil, steam, water, heat, and other products and resources are sold as commodities, and flow meters can provide a basis for transactions between the supply and demand parties. Flow measurement is also an indispensable means for the distribution and management of resources and energy used within a production enterprise.

Today, when people pay more and more attention to saving resources and energy, flow measurement can bring huge economic and social benefits to enterprises. At the same time, in today’s society, people are increasingly aware of the earth, environmental protection, and pollution control on which they depend for survival. Countries all over the world regard the total amount of polluted gas and sewage discharged from industrial production as the control target, and the flowmeter provides scientific and reliable total data, so as to effectively manage and control the discharge outlet.

In many cases, “monitoring purpose” and “measurement purpose” will appear at the same time. For example, when cement slurry is poured in civil construction, using a flow meter to measure the flow of cement slurry can not only control the pouring speed and ensure the pouring quality but also can control the total amount of cement poured through the flow meter according to the calculation requirements, which not only ensures the pouring quality but also No waste of cement slurry.

Another example is the use of flow meters to quickly and accurately complete automatic bagging and canning of beverage production. It not only guarantees the quality of the bags and cans but also improves the work efficiency and reduces the labor intensity of the workers.

For the flowmeter for “monitoring purposes”, the measurement is reliable and stable, and the measurement accuracy is secondary. For the flowmeter for “recording purpose”, not only the measurement is stable and reliable, but also the measurement accuracy is very high. Therefore, for flowmeters that agree to be able to measure fluids, some are only suitable for “monitoring purposes”, and some are suitable for “metering”. For example, positive displacement flowmeters are mostly used for “metering purposes”, and area rotameters are mostly used for “metering purposes”. Monitoring purpose”.