1. Determination of Pump Selection Parameters

1.1 Physical and Chemical Properties of the Medium

The medium’s properties directly affect the pump’s performance, material selection, and structural design. Key considerations include:

Corrosiveness, toxicity

Presence of solid particles (content and size)

Viscosity

Tendency to crystallize

1.2 Process Parameters

Flow Rate (Q):

Minimum, normal, and maximum operational flow rates must be considered.

Select a pump with a rated flow rate between 1.1 to 1.5 times the normal operating flow rate.

Head (H):

Head refers to the net energy increase per unit weight of fluid delivered by the pump.

Rated head should typically be 1.05 times the required system head.

Inlet and Outlet Pressure:

Important for pressure-bearing capacity and seal design.

Temperature (T):

Consider normal, minimum, and maximum inlet temperatures.

NPSH (Net Positive Suction Head):

Ensure the pump’s required NPSH is lower than the available NPSH in the system.

1.3 Pump Type Selection

High head, low flow: Reciprocating pump

Low head, high flow: Axial flow pump

High viscosity media: Screw pump or reciprocating pump

Metering required: Metering pump

2. Classification and Characteristics of Pumps in Chemical Industry

2.1 Classification

Dynamic Pumps: Centrifugal, Vortex, Mixed-flow, Axial-flow

Positive Displacement Pumps: Reciprocating (plunger, diaphragm) and Rotary (gear, screw, lobe)

Others: Jet pumps, Electromagnetic pumps

2.2 Application Ranges

Different pumps are selected based on flow rate, head, and medium characteristics.

2.3 General Selection Principles

| Application | Characteristics | Recommended Pumps |

|---|---|---|

| Feed pumps | Stable flow, high head, cannot stop operation | Centrifugal pump, 100% backup |

| Reflux pumps | Large flow variation, high reliability | Centrifugal pump, 50%-100% backup |

| Circulation pumps | Stable flow, low head, varied media types | Centrifugal pump, 50%-100% backup |

| Product pumps | Small flow, low head, occasional operation | Centrifugal pump, backup optional |

| Sewage pumps | Small flow, corrosive/abrasive media | Sewage or slurry pump |

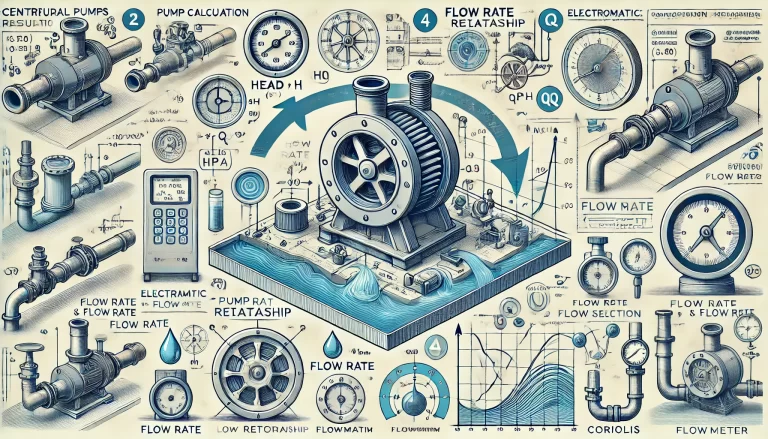

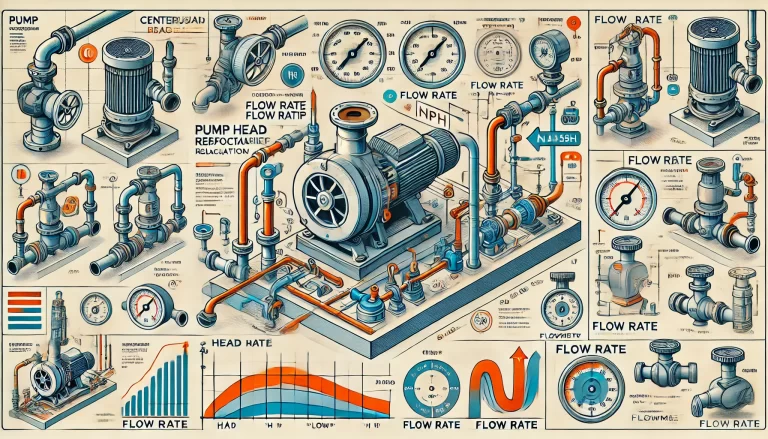

3. Pump Head Calculation and Relationship with Flow Rate

3.1 Basic Formula

The required head can be calculated as:

h = D + S + hf1 + hf2 + hf3 + Pd – Ps

Where:

D: Discharge geometric height (m)

S: Suction geometric height (m)

hf1: Straight pipe friction loss (m)

hf2: Fittings friction loss (m)

hf3: Local loss at inlet and outlet (m)

Pd: Pressure in discharge vessel (m liquid column)

Ps: Pressure in suction vessel (m liquid column)

3.2 Head and Flow Rate Relationship

Pump characteristic curves typically show that as flow rate increases, head decreases.

It is essential to match the pump curve with the system curve to find the operating point.

3.3 Pipeline Layout Considerations

Create preliminary P&IDs and piping layout.

Calculate total equivalent length and fitting losses.

Apply correction factors based on pipe material, fluid properties, and system complexity.

4. Flowmeter Selection Considerations at Pump Outlet

4.1 Fluid Characteristics

Type: Liquid, gas, or steam.

Properties: Temperature, pressure, density, viscosity, corrosiveness, abrasiveness, fouling tendency.

State: Laminar or turbulent flow.

4.2 Flow Range and Accuracy

Flow Range: Normal operating flow should be 30%-70% of the meter’s full-scale range.

Accuracy Requirements:

Trade settlement or process control requires high accuracy.

Trend monitoring may allow lower accuracy.

4.3 Measurement Principle and Method

Measurement Types: Volumetric, mass, instantaneous, cumulative.

Technology Examples:

Electromagnetic (conductive liquids)

Vortex (steam and general-purpose liquids)

Ultrasonic (non-intrusive measurement)

Coriolis (direct mass flow)

4.4 Working Pressure and Temperature

Confirm flowmeter pressure and temperature ratings align with process conditions.

High or low temperature can impact measurement accuracy and material selection.

4.5 Environmental Conditions

Temperature and Humidity: Choose devices rated for site conditions.

Corrosive or Hazardous Areas: Select suitable protection grades (IP, Ex-proof).

Vibration and Interference: Use anti-vibration mounts, electromagnetic shielding if necessary.

4.6 Installation Requirements

Pipe Size: Match meter size to piping or use insertion type for large pipes.

Straight Run Requirements:

Typically 10-20D upstream, 5D downstream.

If not feasible, select meters tolerant to short straight runs (e.g., elbow meters).

Orientation: Install according to manufacturer’s recommendations to avoid air pockets and partial filling.

4.7 Cost and Maintenance

Initial Cost: Balance performance with budget.

Maintenance: Prefer easy-to-maintain meters with readily available spare parts.

Lifecycle Cost: Include recalibration, part replacement, and expected service life.

Conclusion

Selecting the appropriate pump and matching it with a properly chosen flowmeter is crucial for ensuring stable, efficient, and safe operation of industrial processes. Comprehensive consideration of fluid properties, process conditions, environmental factors, and economic aspects must be carried out to achieve optimal performance.