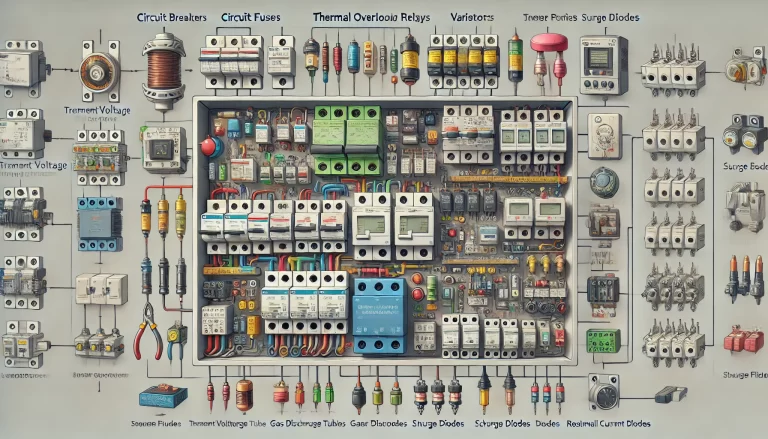

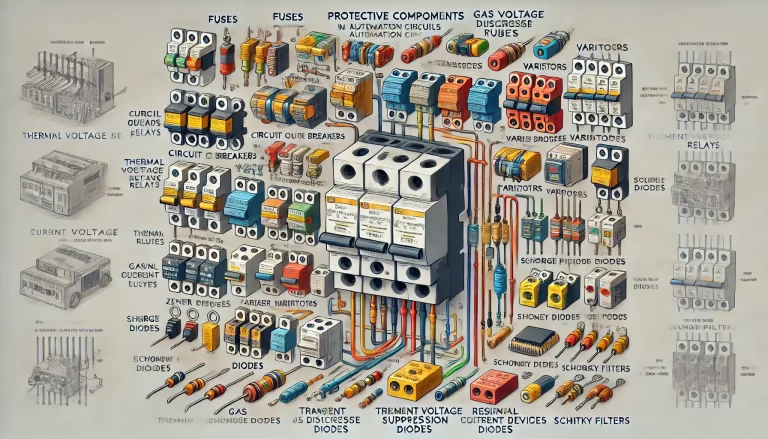

Automation control circuits are critical for ensuring the efficient operation of various industrial processes. To maintain their functionality and prevent damage caused by electrical faults, protective components are integrated into these circuits. These components protect against overcurrent, overvoltage, short circuits, overheating, and other electrical hazards. Below is a detailed exploration of the key protective components used in automation control circuits.

1. Overcurrent Protection Components

Overcurrent conditions occur when the current flowing through a circuit exceeds its designed capacity, potentially causing overheating and damage to the equipment. Common overcurrent protection devices include:

Fuses: These devices contain a thin wire that melts when excessive current flows through it, effectively breaking the circuit and preventing further damage.

Fast-acting fuses: Used for sensitive electronic components.

Slow-blow fuses: Used where temporary surges are expected.

Circuit Breakers: Unlike fuses, circuit breakers can be reset after tripping due to overcurrent. They are commonly used in industrial applications to protect motors and distribution panels.

Thermal-magnetic circuit breakers: Combine thermal (overload) and magnetic (short circuit) protection.

Electronic circuit breakers: Provide precise control and monitoring.

Thermal Overload Relays: These are employed primarily in motor protection and work by sensing excessive heat caused by overcurrent.

PTC (Positive Temperature Coefficient) Thermistors: These resistors increase their resistance with rising temperature, thereby limiting the current and protecting the circuit.

2. Overvoltage Protection Components

Overvoltage can damage sensitive electronics and automation equipment. Protective components that mitigate overvoltage include:

Varistors (MOV – Metal Oxide Varistor): These nonlinear resistors absorb excessive voltage spikes and dissipate energy, commonly used in surge protection devices.

Zener Diodes: These diodes allow current to flow in reverse when voltage exceeds a specific value, regulating and limiting voltage.

Gas Discharge Tubes (GDT): GDTs provide protection by ionizing gas inside the tube and conducting excessive voltage to the ground.

Transient Voltage Suppression (TVS) Diodes: Designed to protect against sudden spikes and transients, TVS diodes react quickly to voltage surges, providing fast response times.

3. Short Circuit Protection Components

Short circuits can cause severe damage due to sudden high current flow. Protective components to prevent this include:

Fast-Acting Fuses: These fuses respond quickly to large surges of current, breaking the circuit almost instantly.

Electronic Fuses (E-Fuses): They offer programmable protection and can automatically reset, making them suitable for modern electronic systems.

Current Limiting Resistors: These resistors restrict the flow of current under fault conditions, protecting downstream components.

4. Overtemperature Protection Components

Excessive heat can deteriorate electronic components, leading to failure. The following protective devices help prevent overheating:

Thermal Fuses: These single-use components open the circuit when a predefined temperature is reached.

NTC (Negative Temperature Coefficient) Thermistors: These decrease in resistance as temperature rises, helping to detect overheating conditions.

Temperature Sensors: Integrated circuits that monitor the temperature and trigger cooling mechanisms or shutdown procedures.

5. Surge Protection Components

Surge protection devices are essential for shielding automation equipment from sudden voltage spikes:

Surge Protectors: These devices incorporate MOVs and GDTs to divert surge currents safely to the ground.

Inductors: Used in power supplies to filter high-frequency surges and noise.

6. Reverse Polarity Protection Components

To prevent damage from incorrect wiring, the following components are used:

Schottky Diodes: These diodes prevent reverse current flow with minimal voltage drop.

Bridge Rectifiers: These circuits ensure correct polarity by automatically adjusting the direction of the current flow.

7. Leakage Current Protection Components

Protecting against electrical leakage is critical to ensure safety and equipment longevity:

Residual Current Devices (RCDs): These monitor the current balance between live and neutral conductors and trip when leakage is detected.

Isolation Transformers: They prevent leakage currents from affecting downstream equipment.

8. Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) Protection Components

Electrical noise and interference can degrade the performance of automation systems. To mitigate such issues, the following components are used:

EMI Filters: These filters suppress conducted interference in power lines.

Ferrite Beads: Small components that absorb high-frequency noise and prevent it from spreading through the circuit.

Shielded Cables: Used to minimize electromagnetic interference in signal transmission.

Conclusion

The selection of appropriate protective components in automation control circuits is crucial to ensuring the reliable and safe operation of industrial systems. By incorporating overcurrent, overvoltage, short circuit, overheating, and EMI protection, engineers can prevent costly damage and maintain operational efficiency. Understanding the roles and applications of these protective devices helps in designing robust automation solutions that can withstand various electrical disturbances.