The Servo Tank Gauge is a high-precision measuring instrument developed based on microelectronics and servo motor drive technology. It provides accurate measurements of liquid level, interface level, density, and multi-point average temperature. It is ideal for inventory management and real-time monitoring of hazardous storage tanks.

This explosion-proof design instrument is suitable for use in flammable and explosive environments, including industries such as petroleum, petrochemicals, electric power, chemicals, pharmaceuticals, and food processing.

Product Features

- Simple installation and modular design with self-diagnosis capabilities

- High measurement accuracy and strong environmental adaptability

- Measurement not affected by sediment or foam on the liquid surface

- One device supports liquid level, interface level, and density measurement & remote display

- Compatible with multi-point temperature probes for layered data collection

- Supports local tank-side display units and remote temperature visualization

- Communication: 4-20mA/HART, RS485 MODBUS

- LCD display with backlight, bilingual (English/Chinese) menu

- High-pressure transparent window for easy maintenance

- Built-in surge protection for lightning and EMI resistance

- Unique weight marking for float position identification

- Integrated calibration chamber, maintenance-free, high reliability

- Suitable for a wide range of tank types and media

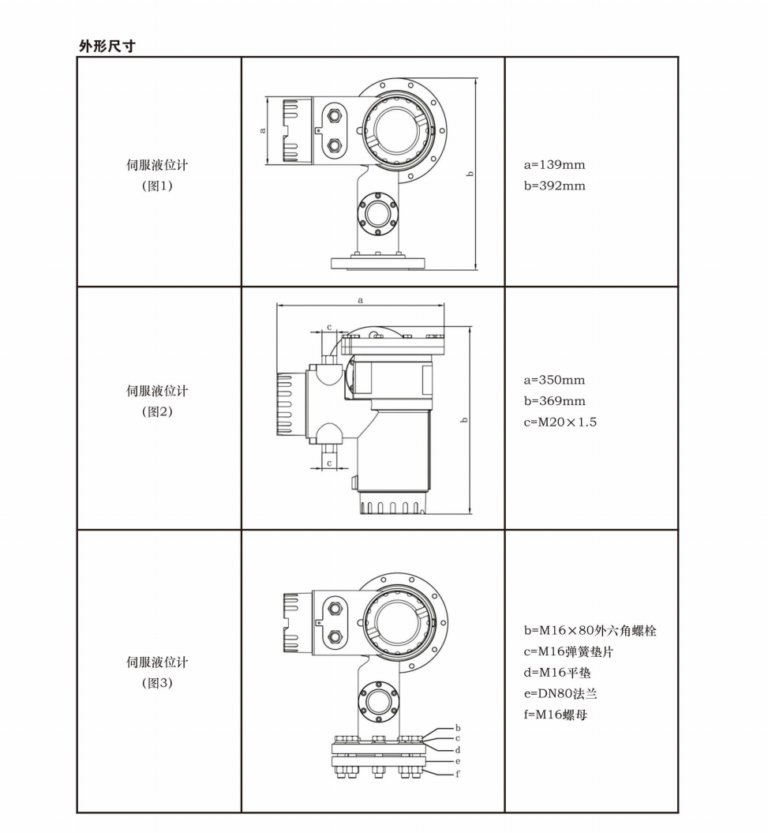

Dimension

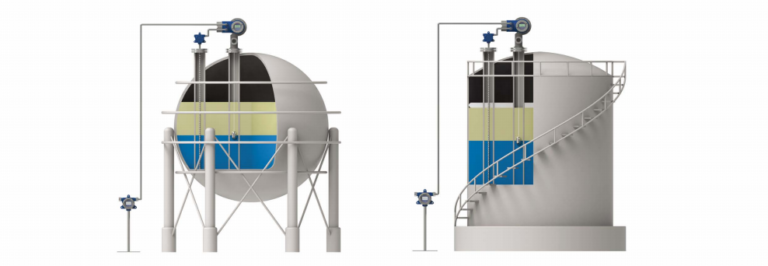

Typical Applications

- Petroleum Industry:From production to tank farms, supports remote inventory and management systems.

- Chemical Industry:Meets the diverse tank configuration requirements of chemical storage.

- Food & Gas Industry:Suitable for applications like LPG/LNG with multi-parameter measurements.

Technical Specifications

Parameter | Specification |

Power Supply | 24VDC / 220VAC |

Measuring Range | 0–50 meters |

Liquid Level Accuracy | ±1mm / ±0.7mm / ±0.1mm |

Resolution | ±1mm / ±0.1mm |

Interface Accuracy | ±1mm / ±0.7mm / ±0.1mm |

Output Signal | 4-20mA / HART / RS485 MODBUS |

Medium Temperature | ≤ 70°C (customizable) |

Process Pressure | ≤ 1.6MPa / ≤ 4.0MPa (customizable) |

Wiring Mode | 4-wire / 6-wire |

Explosion Proof | ExdIICT6 Gb / ExiaIIBT6 Ga |

Protection Rating | IP66 / IP68 |

Safety Level | SIL3 |

Power Consumption | < 15W |

Electrical Interface | M20×1.5 / NPT1/2 / NPT3/4 |

Contact Capacity | 5A / 250VAC |

Relative Humidity | 95% RH |

Float Material | 316L (standard) |

Wire Material | 316L / Hastelloy C276 (optional) |

Drum Housing | 304 / 316L Stainless Steel |

Process Connection | Flanged (custom sizes) |

Multi-Point Temperature Probe

Parameter | Specification |

Temperature Points | 1 to 20 (customizable) |

Accuracy | ±0.5°C / ±0.1°C |

Electrical Interface | NPT1/2 / NPT3/4 (customizable) |

Process Connection | Flanged or Threaded (customizable) |

Installation Guidelines

- Standard flange installation on the tank top is recommended.

- For stability, a guiding tube is suggested to prevent disturbance from liquid turbulence.

- Install in accessible areas for commissioning and maintenance.

- Avoid installation near inlets to prevent float interference.