In the field of industrial automation, process control and motion control represent two fundamentally important control methodologies. Despite their shared purpose of optimizing operations and ensuring high efficiency, they differ significantly in objectives, strategies, system responsiveness, and application areas. This article explores their distinct features to offer a clear understanding of when and where each is most appropriately applied.

1. Control Objectives and Targets

Process Control

Process control primarily focuses on managing physical variables such as temperature, pressure, flow rate, and liquid level in continuous or batch production systems. Its goal is to stabilize these variables to ensure consistent product quality, operational efficiency, and resource optimization.

- Example 1: In chemical production, precise control of temperature, pressure, and material flow in a reactor ensures the desired reaction outcomes and consistent product quality.

- Example 2: In thermal power plants, maintaining boiler water levels is critical. Excessive levels can cause equipment damage due to water carryover with steam, while insufficient levels may lead to dry heating and safety hazards. Process control adjusts pump speeds and valve openings to maintain stable levels.

Motion Control

In contrast, motion control governs the parameters of mechanical motion, such as position, speed, acceleration, and force. It aims to ensure precise and coordinated movements for components or systems.

- Example 1: In CNC machining, motion control ensures precise tool positioning relative to the workpiece to produce components with accurate shapes and dimensions.

- Example 2: For robotic arms in automotive welding lines, motion control achieves highly accurate and repeatable positioning to maintain welding quality and efficiency.

2. Control Strategies and Algorithms

Process Control

Process control relies heavily on feedback mechanisms, with the Proportional-Integral-Derivative (PID) control algorithm being the most commonly used. The PID controller adjusts control inputs by considering the error between the measured and target values, ensuring stability over time. Advanced strategies, such as Model Predictive Control (MPC), are employed for complex scenarios involving multi-variable interactions and significant delays.

- Example: In oil refining, MPC is used to control the distillation process by predicting temperature and flow changes and adjusting heating and reflux ratios accordingly.

Motion Control

Motion control emphasizes trajectory planning, where desired motion paths are predefined. Techniques such as interpolation algorithms convert the trajectory into discrete control commands for actuators. Additionally, advanced methods like nested control loops (position loop, speed loop) and feedforward control improve dynamic performance and accuracy.

- Example: In 3D printers, motion control calculates the movement trajectory for the print head based on the digital model, ensuring precise deposition of material layers to produce high-quality objects.

3. System Response Characteristics

Process Control

Due to the inherent inertia and delays in process systems, their response times are relatively slow. For example, in furnace temperature control, adjustments in fuel supply result in gradual temperature changes over time due to heat transfer dynamics. Process control prioritizes long-term stability and smooth transitions, avoiding aggressive tuning that may cause oscillations.

- Example: In cement production, kiln temperature control requires gradual adjustments to fuel and airflow, ensuring consistent clinker quality over extended periods.

Motion Control

Motion control, on the other hand, demands fast and precise responses. Automated systems such as pick-and-place machines must rapidly start, stop, accelerate, or decelerate while maintaining high positional accuracy.

- Example: In high-speed surface-mount technology (SMT) machines, robotic arms place components on PCBs with sub-millimeter precision in milliseconds, ensuring high productivity and accuracy.

4. Hardware and Software Platforms

Process Control Systems

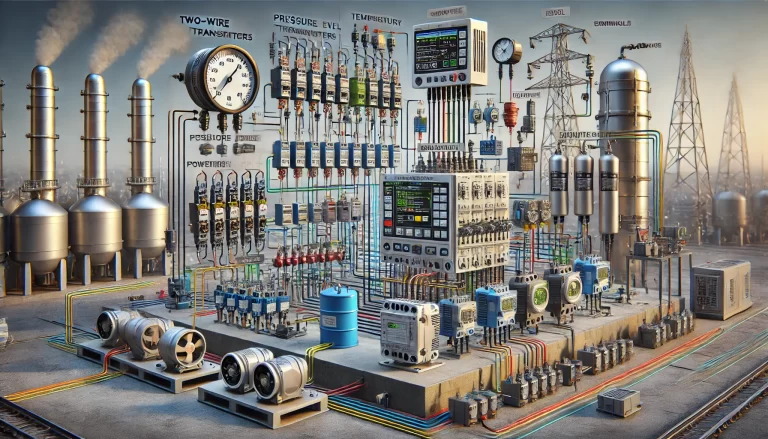

Process control systems typically consist of sensors, transmitters, controllers (e.g., PLCs or DCS), and actuators. Sensors measure variables, transmitters convert these measurements to standardized signals, and controllers process data to generate control outputs for actuators. Software platforms focus on monitoring, alarm management, historical data analysis, and user-friendly human-machine interfaces (HMI).

- Example: In municipal water supply systems, pressure sensors and PLCs work together to regulate pump speeds, ensuring stable water pressure across the distribution network. HMI systems enable operators to visualize and manage real-time operations.

Motion Control Systems

Motion control systems include controllers, drives, and actuators such as motors. Controllers calculate trajectories and issue precise commands, drives translate these commands into actionable signals for motors, and motors execute the desired motion. Software platforms for motion control emphasize real-time responsiveness and dynamic compensation for mechanical effects like inertia and friction.

- Example: In five-axis machining centers, motion controllers calculate the coordinated movement of multiple axes based on CAD/CAM inputs, ensuring precise tool paths and compensating for mechanical deflections.

5. Application Domains

Process Control

Process control dominates in industries with continuous or large-scale production processes such as oil refining, chemical manufacturing, power generation, and pharmaceuticals. These industries benefit from stable, automated systems that optimize efficiency, reduce energy consumption, and enhance safety.

- Example: In pharmaceutical manufacturing, process control ensures strict compliance with temperature, pressure, and purity standards during drug production, guaranteeing consistent quality and regulatory adherence.

Motion Control

Motion control excels in precision-demanding sectors like electronics manufacturing, robotics, printing, packaging, and textile machinery. These systems enhance productivity by executing complex, high-speed, and precise mechanical tasks.

- Example: In smartphone assembly lines, motion control systems perform intricate tasks such as precision alignment, adhesive application, and automated testing, meeting the demands of high throughput and accuracy.

Conclusion and Future Perspectives

While process control and motion control have distinct roles and requirements, they are often complementary in modern industrial systems. For instance, robotic systems in pharmaceutical production combine motion control for mechanical tasks and process control for environmental parameters like temperature and humidity.

As industrial automation advances, the integration of process and motion control will become more seamless, supported by emerging technologies such as artificial intelligence, edge computing, and IoT. These innovations promise to unlock new levels of precision, efficiency, and adaptability, driving industrial automation to unprecedented heights.