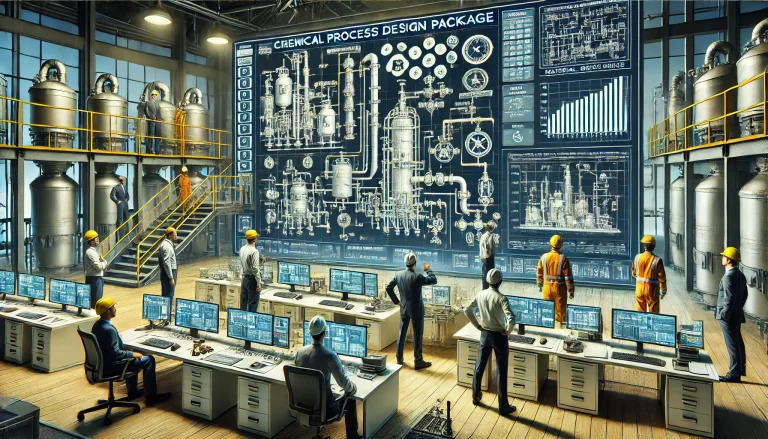

1. Instrument Selection and Installation Standards

1.1 Matching Process Conditions

Select instrument materials based on medium characteristics such as temperature, pressure, and corrosiveness (e.g., 316L stainless steel, PTFE lining).

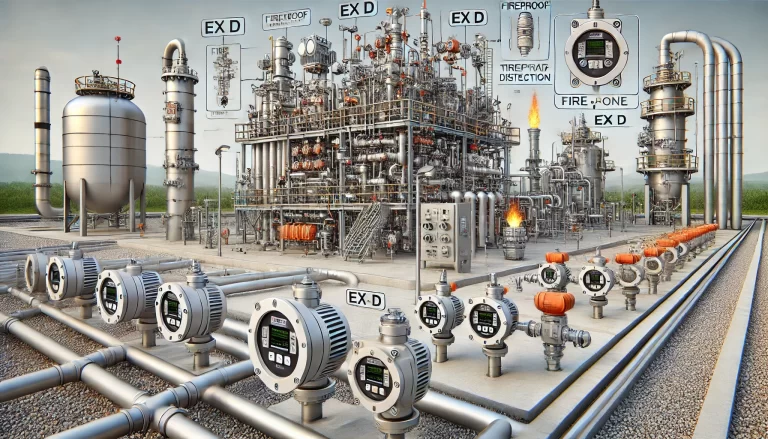

In explosive environments, use explosion-proof instruments certified by ATEX/IECEx.

1.2 Installation Guidelines

Avoid strong electromagnetic interference: keep away from motors and variable-frequency drives; route signal cables in separate conduits.

For pressure and flow instruments, reserve sufficient straight pipe length (e.g., orifice plate: 10D upstream, 5D downstream).

2. Routine Maintenance and Inspection

2.1 Regular Cleaning

Wipe dust from instrument housings and remove deposits on probes (e.g., ultrasonic level sensor transducers).

Use compressed air to clean dust-prone ventilation slots at least twice per year.

2.2 Condition Monitoring

Daily checks: observe display stability, check indicator lights, and listen for abnormal actuator noises.

Weekly records: compare historical data and analyze trends; if temperature drift exceeds ±2%, perform recalibration.

3. Calibration and Verification

3.1 Calibration Intervals

Pressure gauges and transmitters: calibrate every 6–12 months using a standard pressure calibrator.

Analytical instruments (e.g., pH meters, flowmeters): shorten intervals in corrosive or unstable media (e.g., every 3 months).

3.2 Documentation

Maintain calibration logs including dates, error values, and adjustment parameters for traceability and compliance.

4. Environmental and Protective Measures

4.1 Temperature and Humidity Control

Control room: install air conditioning to maintain 20 ± 5 °C and 45–75% RH.

Field instruments: use enclosures, insulation boxes, or heating tapes to prevent condensation and icing.

4.2 Anti-Corrosion and Anti-Vibration

In corrosive environments, apply protective coatings and regularly check sealing gaskets for aging.

In high-vibration areas, add damping mounts and tighten wiring terminals to prevent loose contacts.

5. Spare Parts Management and Personnel Training

5.1 Spare Parts Strategy

Keep essential spares such as sensors, power modules, and actuators (maintain 1–2 sets depending on usage frequency).

Test spare parts every six months by powering them up to confirm functionality.

5.2 Skill Development

Conduct specialized training for instrument technicians (fault diagnosis, calibration practices).

Organize emergency drills, e.g., rapid repair procedures for explosion-proof instrument failures.

6. Intelligent Monitoring and Early Warning

Deploy monitoring systems via DCS/PLC to collect real-time data and set high/low limit alarms (e.g., high-pressure alarm with audible/visual alerts).

Use historical data for predictive maintenance, such as vibration spectrum analysis to forecast mechanical wear.

Core Principle

By adhering to the principle of “prevention first, supported by corrective actions”, standardized management can significantly reduce the probability of unexpected instrument failures and ensure safe, reliable chemical production.