1. General Provisions

Purpose

This system is established to ensure the long-term, stable, safe, and efficient operation of instrumentation equipment. By preventing unexpected failures, minimizing unplanned downtime, reducing maintenance costs, and extending equipment service life, it safeguards production continuity and process safety.

Scope of Application

Applicable to all in-service instrumentation equipment within the company, including but not limited to:

Field instruments: pressure, temperature, flow, level, and composition analyzers

Control systems: SIS, DCS, GDS, PLC

Final control elements: control valves, shut-off valves, actuators, and accessories

Supporting equipment: signal/power cables, junction boxes, etc.

Management Principles

Follow the principles of prevention first, planned approach, hierarchical management, and accountability. Preventive maintenance shall be performed through scientific planning, standardized execution, comprehensive documentation, and continuous improvement.

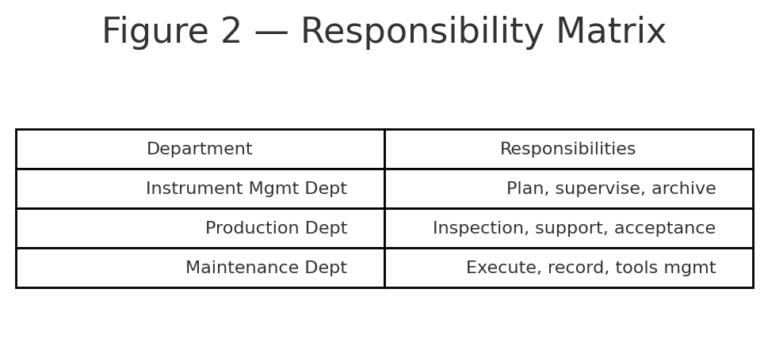

2. Responsibilities

2.1 Instrumentation Management Department

Formulate and revise the preventive maintenance system.

Conduct classification and risk-based evaluation of all instruments to define maintenance cycles and content.

Develop annual and monthly maintenance plans and distribute them to relevant departments.

Provide technical guidance and resolve technical challenges during maintenance.

Establish and manage equipment archives (operation logs, maintenance records, calibration certificates).

Submit spare parts and special tool purchase plans.

Supervise, inspect, and evaluate preventive maintenance implementation.

Organize skill training and technical exchanges for personnel.

2.2 Process & Production Department

Perform daily inspections and basic maintenance (cleaning, monitoring) of instruments.

Report abnormal instrument conditions in their area to the management department.

Cooperate with preventive maintenance by preparing process conditions (isolation, depressurization, purging).

Participate in post-maintenance functional testing and acceptance.

2.3 Instrument Maintenance Department

Carry out maintenance and repair according to the plan, SOPs, and safety requirements.

Record inspection findings, corrective actions, spare parts replaced, and test results.

Conduct self-inspection after completion to ensure quality.

Manage tools and maintenance equipment on a daily basis.

3. Preventive Maintenance Planning

Plan Elements

Maintenance plans shall specify schedule, scope, responsible personnel, required tools, and materials.

Classification & Grading

Critical Instruments: SIS, shutdown valves, safety-critical loops. → Strictest preventive measures, shorter cycles, additional inspections.

Important Instruments: Instruments affecting product quality, energy efficiency, or environmental compliance.

General Instruments: Routine process monitoring instruments.

Cycle Determination

Based on manufacturer manuals, industry standards, historical failure data, and environmental conditions (temperature, pressure, corrosion, explosive atmosphere).

For newly commissioned or significantly modified equipment, initial cycles should be shortened.

Adjustments to cycles must be documented and communicated in advance.

Maintenance Content

Cleaning & Protection: Remove dust, oil, and deposits. Apply anti-corrosion treatment if required.

Lubrication & Tightening: Lubricate moving parts; check and tighten electrical/mechanical connections.

Spare Part Replacement: Replace consumables such as filters, seals, or aged cables.

Calibration & Testing: Perform calibration and functional verification to ensure accuracy and reliability.

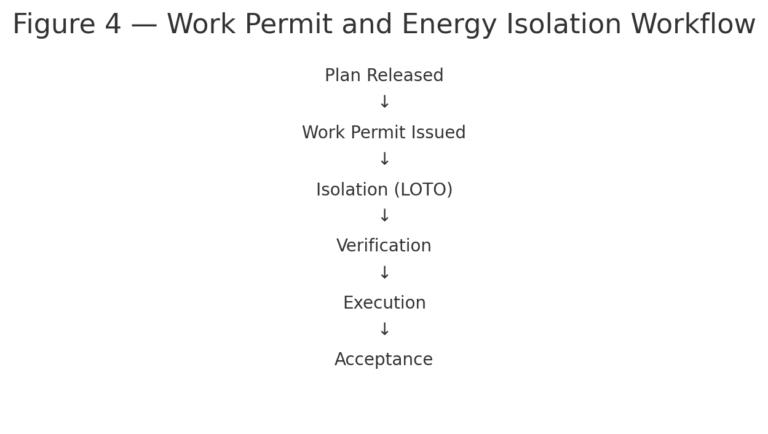

4. Implementation of Preventive Maintenance

Preparation

Plans distributed by the management department in advance.

Process department ensures safe conditions (isolation, purging, depressurization).

Maintenance team prepares personnel, tools, PPE, spare parts, and work permits.

Execution

Workers must comply with safety procedures and use PPE.

Follow work permit and energy isolation requirements (lock-out/tag-out, depressurization, gas isolation).

In hazardous areas, prohibit live maintenance of non-intrinsically safe instruments.

Use explosion-proof tools where required.

Ensure spare parts meet technical specifications and are properly labeled.

Adopt environmental protection measures for waste disposal.

Quality Inspection & Acceptance

Self-check by maintenance personnel upon completion.

Joint testing and acceptance by management and production departments.

Only after acceptance can the instrument be returned to service.

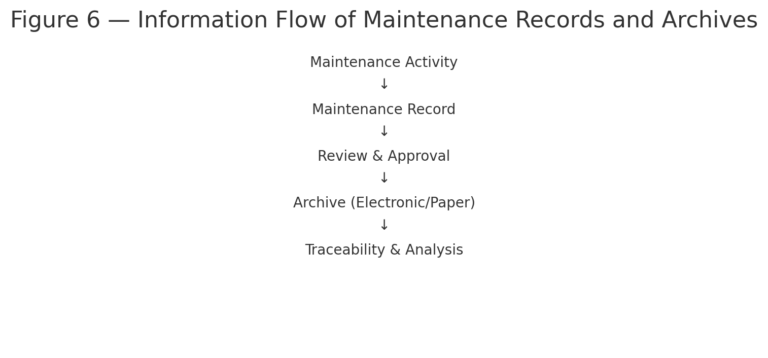

5. Documentation & Archiving

Maintenance Records: Each activity must be recorded in the “Preventive Maintenance Log” with details: tag number, equipment name, date, executor, inspection findings, corrective actions, spare parts, calibration results, acceptance signature.

Archives: Centralized archiving of records, calibration certificates, fault analysis, and equipment change logs. Records must be clear, accurate, and retrievable for traceability.

6. Supervision, Assessment, and Continuous Improvement

Supervision: Management department inspects execution rate, quality, record completeness, and safety compliance.

Performance Assessment: Execution results integrated into KPIs:

Preventive maintenance completion rate ≥ 95%

Sudden instrument failure rate ≤ 3% annually

Maintenance record completeness ≥ 98%

Continuous Improvement: Analyze maintenance data, evaluate strategy effectiveness, and dynamically adjust cycles and procedures.

7. Supplementary Provisions

This system is interpreted by the Instrument Management Department.

Effective from the date of issuance.