Electromagnetic flow meters are widely used in various industries for their accuracy and reliability. However, in applications involving contaminated or chemically active fluids, inner wall fouling and electrode scaling can affect measurement accuracy and device lifespan. This guide outlines both preventive strategies and cleaning methods to mitigate buildup and maintain performance.

I. Preventive Measures

1. Optimize Electrode and Liner Materials

Electrode Material: Choose corrosion-resistant and anti-fouling materials based on the medium. For example, platinum electrodes are ideal for wastewater due to their smooth surface and chemical stability.

Liner Material: Use PTFE (polytetrafluoroethylene) or polyurethane liners. PTFE offers non-stick and corrosion-resistant properties, while polyurethane is more wear-resistant and suitable for media containing solid particles.

2. Maintain Proper Flow Velocity

A higher fluid velocity (recommended ≥ 2 m/s) promotes self-cleaning by flushing away deposits. However, excessive velocity may cause abrasion on electrodes or liners, so balance is essential.

3. Improve Pipe and Electrode Design

Ensure smooth inner surfaces in the upstream and downstream piping to prevent turbulence and stagnation zones that promote fouling.

Use self-cleaning electrode structures, such as protruding or contoured designs, to create fluid disturbances that reduce particle accumulation.

4. Medium Pretreatment

Install filters or sediment traps before the flow meter to remove suspended solids, precipitates, or debris that contribute to buildup.

5. Regular Maintenance and Calibration

Conduct periodic inspections to detect early scaling or debris.

Perform scheduled calibrations to ensure measurement accuracy and compensate for any surface interference caused by light fouling.

II. Cleaning Methods

1. Online Cleaning (No Dismantling Required)

Mechanical Scraping: Some models support built-in scrapers or rotating cleaning devices that remove fouling from electrodes.

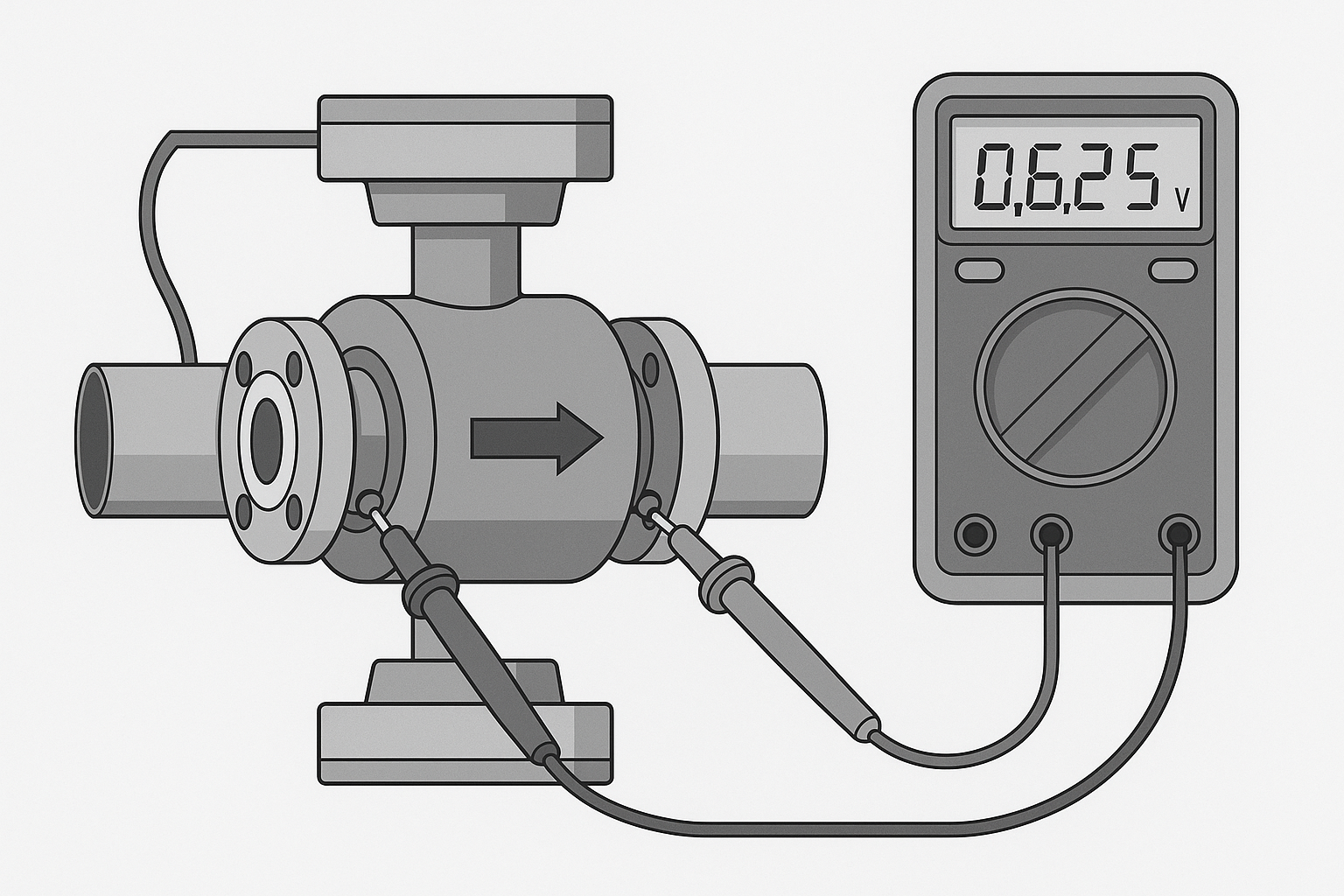

Electrochemical Cleaning: Use controlled electrolytic reactions to dissolve conductive scale like metal oxides.

Ultrasonic Cleaning: Apply ultrasonic waves to dislodge soft or fine fouling without damaging the electrode surface.

2. Offline Cleaning (Requires Disassembly)

Chemical Soaking: Immerse components in mild acids or neutral cleaning agents (e.g., citric acid) to dissolve stubborn scale. Avoid aggressive chemicals that may damage the liner or electrodes.

Manual Wiping: Gently clean surfaces with a soft cloth or sponge and warm water. Do not use abrasives that may scratch the surface.

3. Emergency Cleaning (Severe Buildup)

Electrical Breakdown Method: For non-conductive deposits (e.g., resin or colloids), apply high-voltage pulses to break down and detach the fouling layer.

III. Important Considerations

Avoid Physical Damage: Never use metal brushes, blades, or sharp tools during cleaning to prevent irreversible damage to electrodes and liners.

Environmental Protection: Install meters in climate-stable, corrosion-free environments when possible to reduce fouling rates.

Professional Handling: For severe or repeated fouling issues, consult the manufacturer or certified service providers rather than attempting disassembly without guidance.

Conclusion

By applying the above preventive and cleaning practices, users can significantly reduce fouling in electromagnetic flow meters, ensuring long-term accuracy and reliability. If scaling recurs frequently, it may be necessary to reevaluate medium characteristics, meter selection, or process conditions for optimal compatibility.