Why Some Are Long and Others Are Short?**

Differential pressure (DP) flow meters measure flow by detecting the pressure drop created across a primary element—such as an orifice plate, Venturi tube or wedge flow meter.

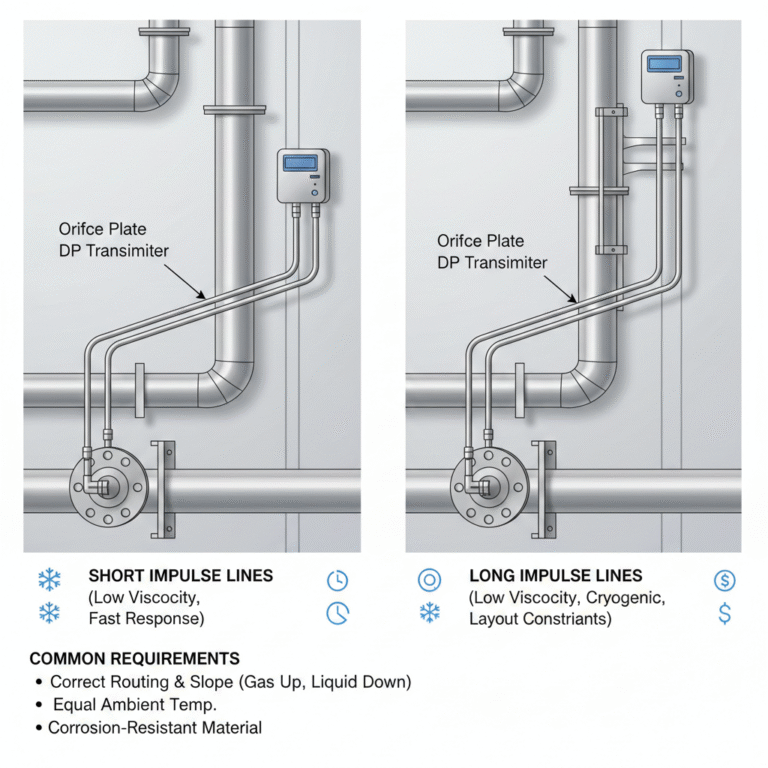

To transmit this pressure difference to the transmitter, two impulse (tapping) lines are installed between the process piping and the DP transmitter.

In engineering practice, these tapping lines may be long or short, depending on the field conditions.

Both configurations serve the same purpose, but they differ significantly in performance, cost, and installation quality.

This article explains the reasons, differences, and common requirements.

Why Do Impulse Lines Have Different Lengths?

✔ 1. Nature of the Process Fluid

Easily vaporizing liquids (e.g., LNG, LOX, cryogenic service)

Longer lines are required to stabilize the two-phase condition and avoid vapor flashing inside the tube.

A longer distance helps ensure single-phase flow, which is critical for accurate DP measurement.High-viscosity mediums

Thick liquids increase internal resistance and response delay. In this case, short impulse lines are preferred to minimize friction losses and slow signal transfer.

✔ 2. Installation Environment and Layout Constraints

If the DP transmitter can be mounted close to the tapping points, a short line is ideal.

When the transmitter must be installed far away due to heat, vibration, accessibility or pipe routing, longer impulse tubing becomes necessary.

✔ 3. Required Measurement Response

Impulse line length directly affects how fast pressure signals reach the transmitter:

Shorter lines → higher natural frequency + faster response

Longer lines → noticeable damping and time delay

For applications with rapidly changing flow or pulsating pressure, short lines offer more stable performance.

Key Differences Between Long & Short Impulse Lines

🔍 1. Measurement Accuracy

Short lines transmit pressure with minimal attenuation, temperature effect, or phase separation.

Long lines may cause:

Pressure loss

Signal distortion due to temperature gradients

Liquid collection in gas measurements

Gas entrapment in liquid service

Accuracy depends heavily on slope design and proper draining/venting.

⏱ 2. Response Speed

Short → fast response, ideal for fluctuating process flow

Long → slower damped signal, not suitable for dynamic control or frequent variations

🔧 3. Installation Complexity & Maintenance

Short impulse lines

Less material and fittings

Fewer leak points

Lower cost and easier troubleshooting

Long impulse lines

More piping supports and valves

Higher probability of leaks and blockages

Higher lifecycle cost

Common Requirements for Both Configurations

Regardless of length, all impulse lines must follow these best practices:

⭐ Correct Function

Deliver the upstream and downstream pressure signals reliably to the differential pressure transmitter.

⭐ Proper Material

Choose corrosion-resistant tubing based on the fluid.

Stainless steel is commonly used for water, steam, oil and most chemical fluids.

⭐ Correct Routing and Slope

To avoid trapped gas or liquid:

Gas service → tubing slopes upward to the transmitter

Liquid service → tubing slopes down from pipe to transmitter

Steam → use condensate pots, keep both at same elevation

⭐ Equal Ambient Temperature

Both tubes should run side-by-side where possible to minimize thermal imbalance and zero drift.

Final Thoughts

Impulse line design plays a crucial role in the performance of differential pressure flow meters.

Choosing between long and short tapping lines depends on:

Fluid properties

Layout restrictions

Accuracy and response time requirements

A short and well-installed impulse line almost always delivers the best measurement, but proper engineering and installation can make longer runs work reliably.