In the specialized environment of cold storage, accurate pressure measurement is critical to the stable operation of refrigeration systems and the safe preservation of stored goods. However, the low temperature and high humidity conditions commonly found in cold storage facilities pose significant challenges to the performance and reliability of pressure gauges.

Understanding how pressure gauges function in cold environments, the problems they face, and the appropriate countermeasures can help operators maintain system stability and ensure long-term operational safety.

1. The Role of Pressure Gauges in Cold Storage

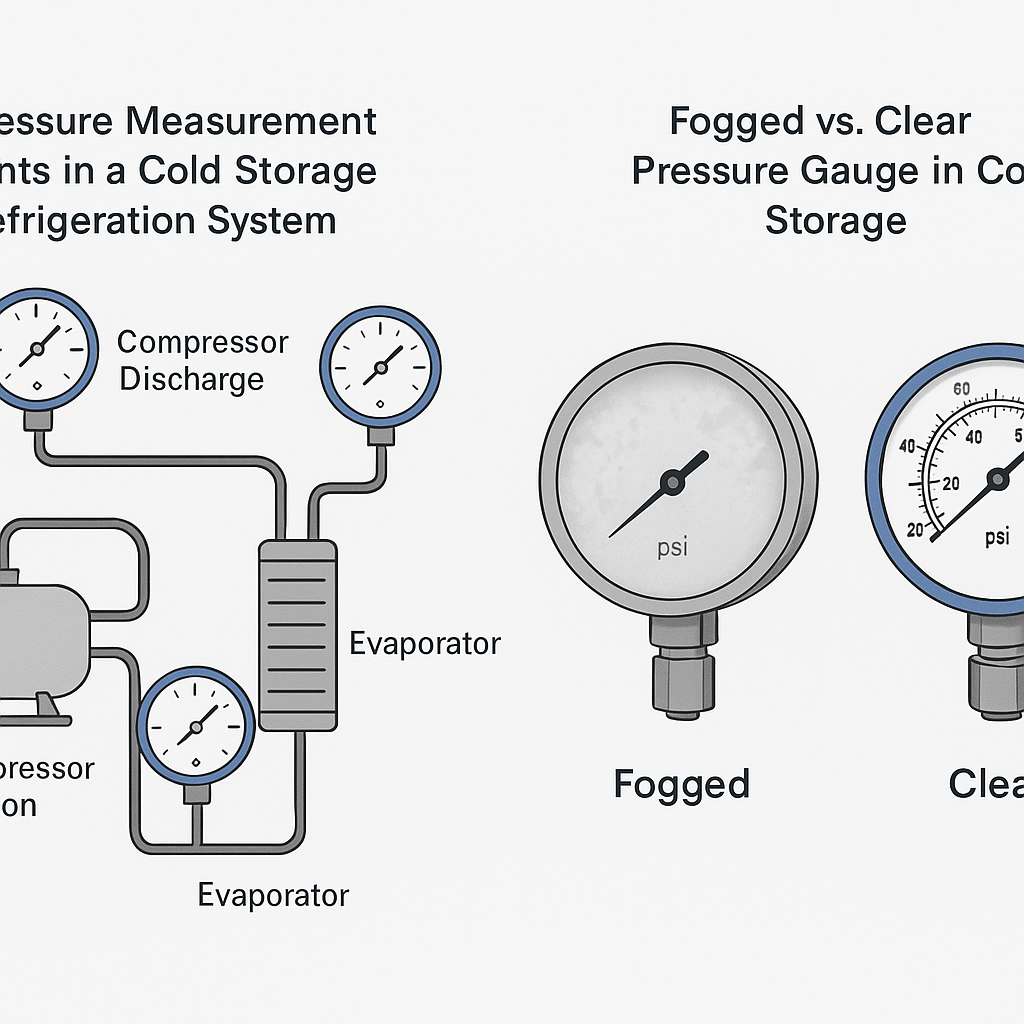

Pressure gauges are instruments used to measure the pressure of gases or liquids. In cold storage applications, they are primarily used to monitor the pressure of refrigerants in various parts of the refrigeration system, including:

Suction pressure of compressors

Discharge pressure of compressors

Pressure inside condensers

Pressure inside evaporators

These pressure readings are essential indicators of the system’s operating status. By analyzing these values, operators can detect issues such as refrigerant leaks, pipe blockages, or compressor malfunctions early, allowing for timely interventions to ensure efficient cooling and product safety.

2. Challenges Faced by Pressure Gauges in Cold Storage

❄️ Low Temperatures

Mechanical stiffness: At very low temperatures, lubricants inside the gauge may thicken or freeze, causing the pointer to move sluggishly or stick.

Condensation and icing: Sudden temperature fluctuations or poor insulation can lead to condensation or icing inside the gauge housing, affecting readability and internal components.

💧 High Humidity

Fogging or internal corrosion: Moisture ingress through poorly sealed housings can cause fogging on the dial window or corrosion of internal metal components, especially in electrical contact gauges.

Electrical faults: In gauges with signal outputs, humidity may cause insulation failure or short circuits.

3. Countermeasures and Best Practices

To ensure pressure gauges perform reliably in cold storage environments, the following solutions are recommended:

Use glycerin- or silicone-filled gauges to dampen vibrations and resist freezing. Silicone oil remains fluid at lower temperatures than glycerin.

Select pressure gauges with antifog glass and sealed enclosures rated at least IP65 or higher.

Install gauges in locations with some thermal buffering, avoiding direct exposure to cold air blasts or condensation points.

Apply heat trace or insulation wraps to gauges in extreme low-temperature zones.

Use gauges with stainless steel internals for corrosion resistance, especially when humidity is high.

Regular inspection and calibration, especially after defrost cycles or system shutdowns, to ensure performance accuracy.

4. Recommended Pressure Gauge Features for Cold Storage

| Feature | Recommendation |

|---|---|

| Temperature range | -40°C to +60°C |

| Case material | Stainless steel or corrosion-resistant alloy |

| Filling fluid | Silicone oil (for low temp), glycerin |

| Ingress protection | IP65 or higher |

| Mounting type | Back or bottom connection with seal fitting |

| Optional features | Heating element, remote signal output |

6. Conclusion

Pressure gauges are vital monitoring tools in cold storage systems. However, their performance can be significantly affected by the environmental challenges of low temperature and high humidity. By selecting suitable gauge models and implementing effective protection strategies, facility operators can ensure accurate pressure monitoring, early fault detection, and overall system reliability.