Overview:

Differential pressure flow meters are widely used in industrial applications to measure flow rates by calculating the difference in pressure across a restriction in the pipe. It is common for the original range of the flow meter to be inadequate once the system is in operation. This article discusses how to handle such situations and adjust the range effectively.

1. Requirements for the Isolation Liquid in Differential Pressure Flow Meters:

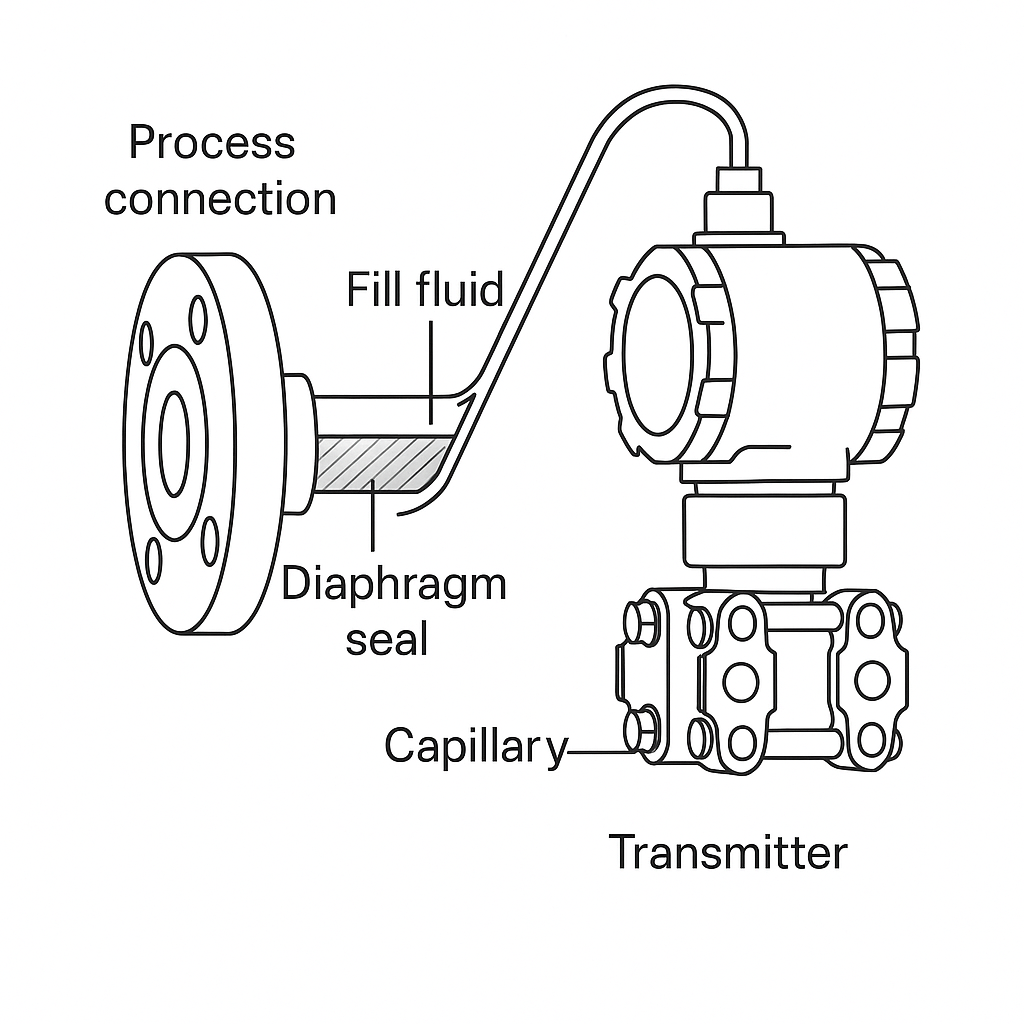

The isolation liquid in differential pressure flow meters serves to isolate the measuring medium from the meter, preventing issues such as corrosion, freezing, or crystallization. The isolation liquid should meet the following criteria:

Chemical Stability: It must not chemically react with the measured medium, avoiding decomposition, polymerization, or combustion.

Physical Stability: The liquid must not mix, evaporate, freeze, or crystallize when in contact with the measured medium.

Corrosion Resistance: It should not corrode the meter or the connecting pipe.

Temperature Resistance: The liquid must remain stable under both high and low-temperature conditions, without evaporating at high temperatures or freezing at low temperatures.

Viscosity: The viscosity should be low enough to allow for easy filling of the meter.

Density: There should be a suitable density difference between the isolation liquid and the measured medium to prevent significant errors in pressure readings.

Safety: The isolation liquid should be non-toxic and safe to handle.

Economic Feasibility: It should also be cost-effective.

2. Adjusting the Range After Commissioning:

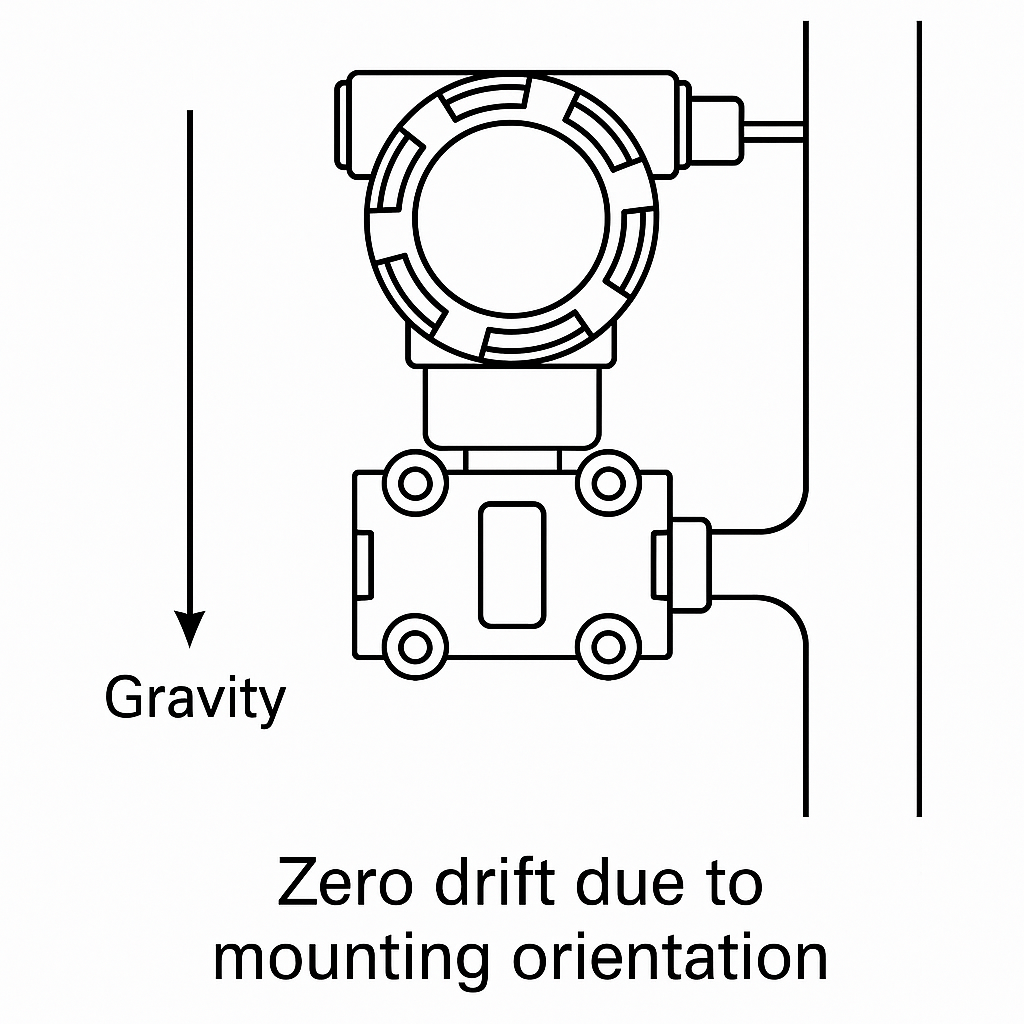

It is common to find that the original range of the differential pressure flow meter is no longer suitable after commissioning. When adjusting the range, consider the following points:

Expanding the Range: If the range is increased, the maximum differential pressure (upper pressure limit) will rise significantly, causing greater pressure loss. If this increase is unacceptable for the process, consider changing the differential pressure device.

Reducing the Range: If the range is decreased, the upper pressure limit will reduce, and it’s necessary to check if this new limit is acceptable for the system. If the new limit is problematic, you may need to redesign the differential pressure device.

Recalculating the Pressure Limit: If neither of the above issues is encountered, simply use the new range and the typical flow rate to recalculate the differential pressure limit using the meter’s design program.

Without Design Program: If you do not have access to the differential pressure flow meter design program, and the flow display device has automatic compensation for the nonlinear flow coefficient or the expansion coefficient, you can use the relationship that differential pressure is proportional to the square of the flow rate to recalculate the differential pressure limit without increasing the error.

Without Compensation Features: If the flow display device lacks automatic compensation for nonlinearity, recalculating the differential pressure limit using the square of the flow rate may introduce some errors due to nonlinearity in the flow coefficient and expansion coefficient.

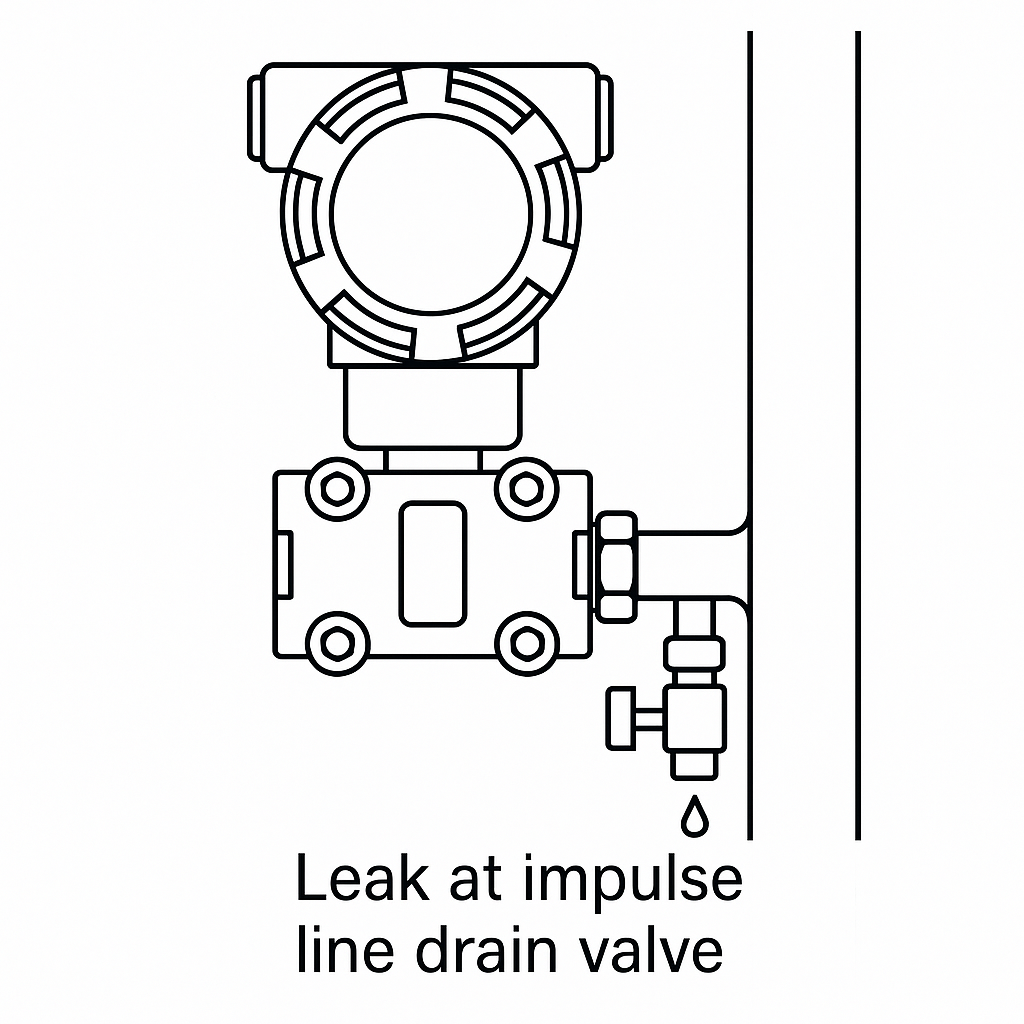

3. Proper Installation of Differential Pressure Signal Tubes:

It is essential for the positive and negative pressure tubes of the differential pressure signal to have the same diameter and follow the same routing. The tubes should be as close together as possible to ensure accurate readings. This is because pressure signals in both tubes will experience some delay. When the diameters, lengths, and orientations are the same, the time constants for both tubes will be identical, and this prevents dynamic errors caused by different response times.

Additionally, placing the tubes near each other helps to equalize the temperatures of the mediums within, preventing density differences that could cause errors in the differential pressure readings.

4. Pre-tensioning of Standard Orifice Plates in Cryogenic Applications:

For flow measurement of cryogenic media, the differential pressure device should be pre-tensioned when installed in pipelines carrying such media. Cryogenic temperatures cause the materials in the differential pressure device to contract, leading to potential leaks if not pre-tensioned at lower temperatures. Pre-tensioning ensures that the device maintains its integrity under extreme conditions. A more reliable solution is to use materials for the differential pressure device that are the same as those used in the pipeline and weld them together.

Conclusion:

Adjusting the range of a differential pressure flow meter after commissioning requires a careful review of the system’s conditions and recalculating pressure limits accordingly. Ensuring that the isolation liquid is appropriate and that the installation of the differential pressure signal tubes follows best practices are crucial for maintaining accuracy and reliability. By considering these factors, operators can ensure that their differential pressure flow meters continue to perform optimally throughout their lifecycle.