Pressure gauges are critical instruments for monitoring pressure in various industrial systems. To ensure measurement accuracy, personnel safety, and equipment reliability, it is essential to follow standardized procedures during maintenance and inspection. This guide outlines key precautions and best practices.

1. Safety Preparation

🔌 Power Isolation and Pressure Release

Disconnect power supply to related equipment to prevent electric shock.

Slowly release the pressure medium (gas or liquid) in connected pipelines before disassembly to avoid injury from sudden discharge.

🌡️ Environmental Conditions

Ensure a clean, dry, and vibration-free environment. Avoid strong magnetic fields or high temperatures that can affect accuracy.

In corrosive environments, wear protective gloves and goggles to prevent chemical exposure.

🧰 Tools and Spare Parts

Use proper tools such as wrenches, screwdrivers, and calibration instruments to prevent mechanical damage.

Check the compatibility of spare parts (e.g., seals, springs, pointers) with the target gauge in advance.

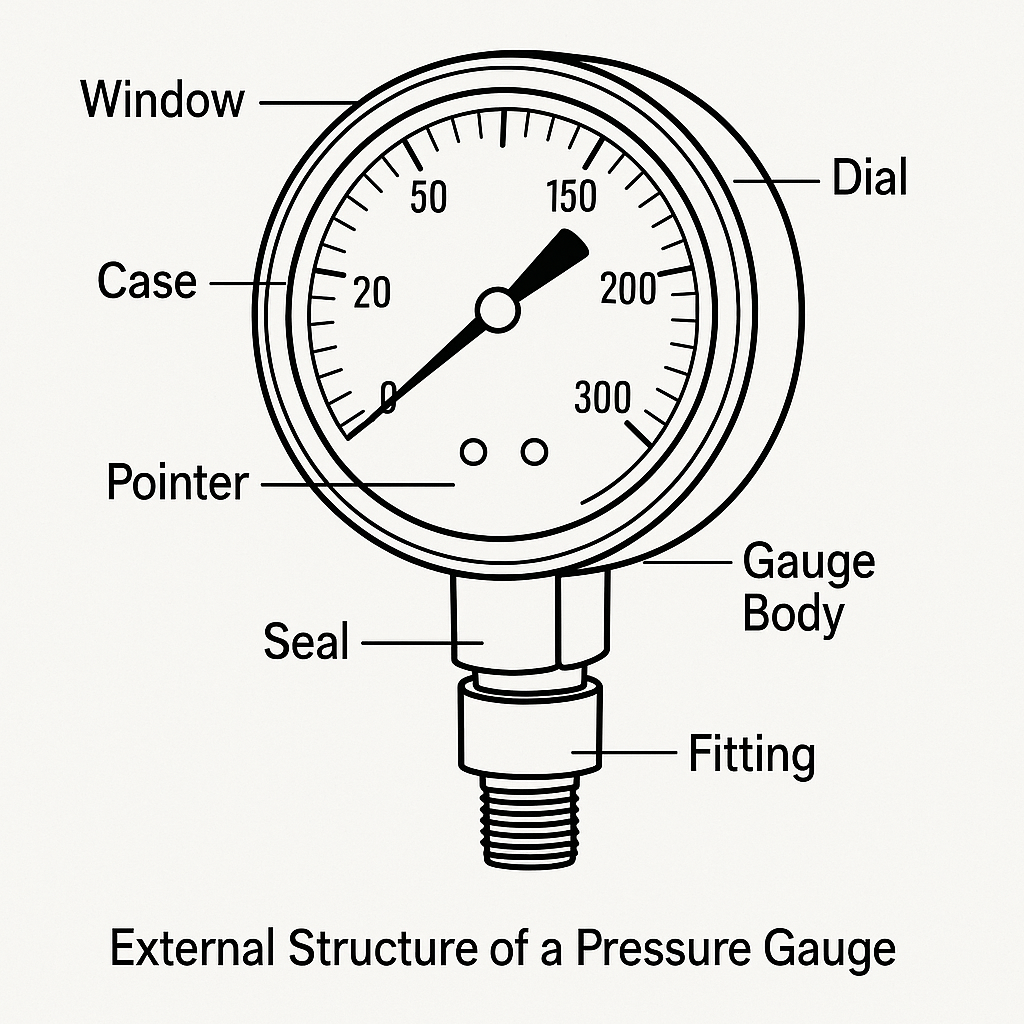

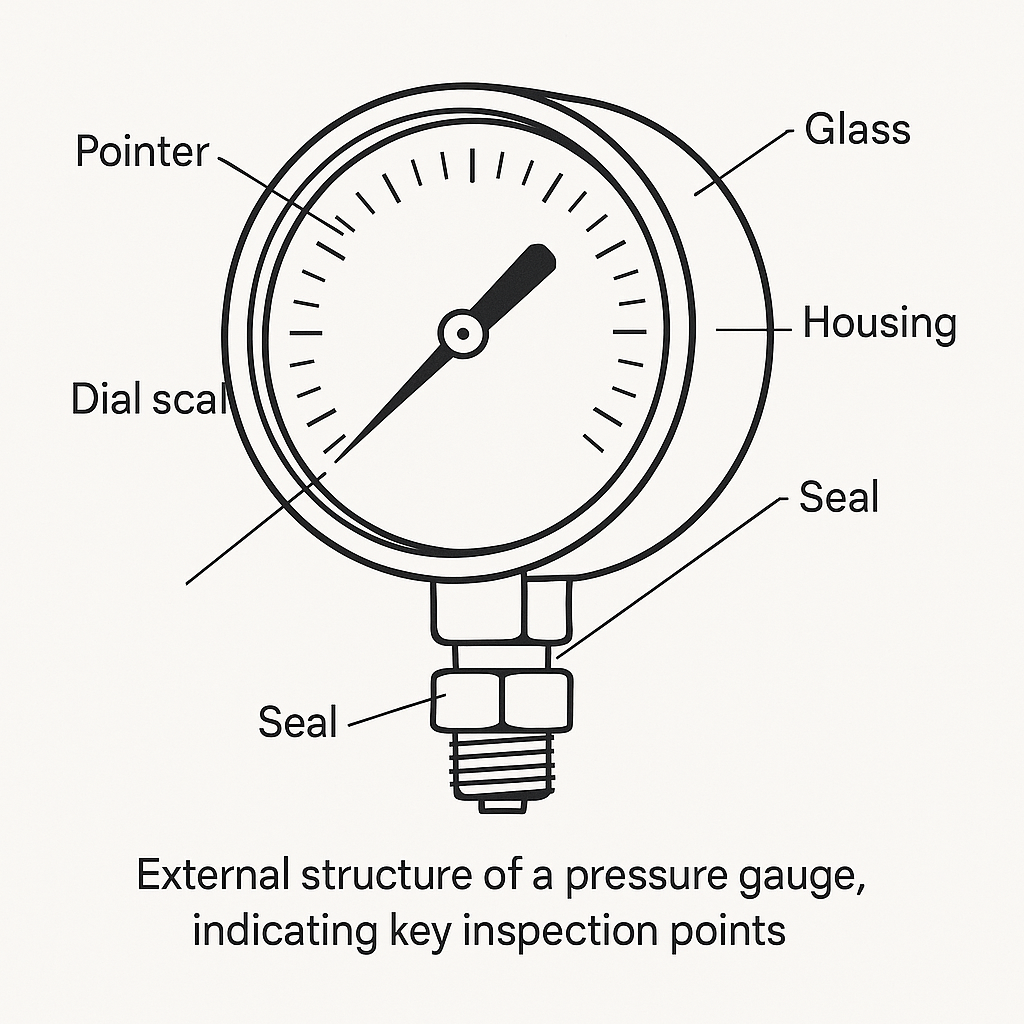

2. Disassembly and External Inspection

🛠️ Correct Disassembly

Mark the mounting direction and position for accurate reinstallation.

Loosen connections gently to avoid thread damage or deformation.

🔍 External Visual Inspection

Examine the housing for cracks, rust, or deformation.

Check if the dial scale is legible and if the range matches application needs.

Verify the integrity of seals or lead marks for metrological instruments.

3. Internal Component Inspection

⚙️ Movement and Transmission Mechanism

Clean internal dust and grease after removing the movement.

Inspect gears, levers, and springs for wear, corrosion, or looseness.

Gently move the pointer to test smoothness, accuracy, and zero-return capability.

🌀 Sensitive Elements

For Bourdon tube gauges, check for cracks, deformation, or leaks. Perform pressure integrity tests if needed.

For diaphragm or bellows types, inspect for aging, seal edge tightness, and rupture.

🔌 Electrical Components (for contact-type gauges)

Inspect contact points for oxidation or burns.

Confirm the reliability of terminal connections and insulation.

Test control/alarm logic for proper actuation.

4. Calibration and Adjustment

🧪 Calibration Setup

Use a high-accuracy reference gauge (1–2 grades higher) or a calibration bench.

Ensure ambient temperature is within 20 ± 5°C. Let the gauge stabilize before calibration.

⚖️ Calibration Steps

Increase pressure to 25%, 50%, 75%, and 100% of the range. Compare readings with the reference gauge.

Decrease pressure to zero and check for return error (typically ≤ absolute value of max permissible error).

Calculate absolute and hysteresis errors at each step. If out of tolerance, adjust or replace parts.

🔧 Adjustment Techniques

For linear deviation, correct pointer or transmission ratio.

For nonlinear errors, inspect deformation in sensing elements or wear in gears.

5. Reinstallation and Acceptance

🔄 Correct Reinstallation

Restore the gauge based on prior markings, ensuring upright positioning and leak-tight fittings.

Use proper sealants (e.g., PTFE tape) without obstructing internal passages.

🧪 Trial Operation

Slowly increase system pressure to operating level. Observe for leaks or pointer fluctuation.

Run for at least 30 minutes and verify reading stability and absence of abnormal noise.

For legally regulated instruments, reapply inspection labels and document calibration results.

6. Maintenance Records and Preventive Plan

📘 Documentation

Maintain detailed records including:

Model, range, accuracy class

Inspection date, failure symptoms

Parts replaced, calibration data

📆 Preventive Maintenance

Perform visual checks monthly and recalibrate semiannually.

In harsh environments (corrosive, high-vibration), shorten maintenance intervals and consider protective add-ons like isolators or snubbers.

7. Special Gauge Types

| Type | Precaution |

|---|---|

| Oxygen Pressure Gauges | Must be completely oil-free. Use dedicated tools to prevent combustion risk. |

| Explosion-Proof Gauges | Ensure flameproof housing is intact. Do not open under power in hazardous zones. |

| Digital Pressure Gauges | Check battery and display. Avoid moisture. Calibrate with digital reference instruments. |

Conclusion

By following these standardized procedures, maintenance personnel can ensure the safety, reliability, and accuracy of pressure gauges—critical components in industrial monitoring and control systems.