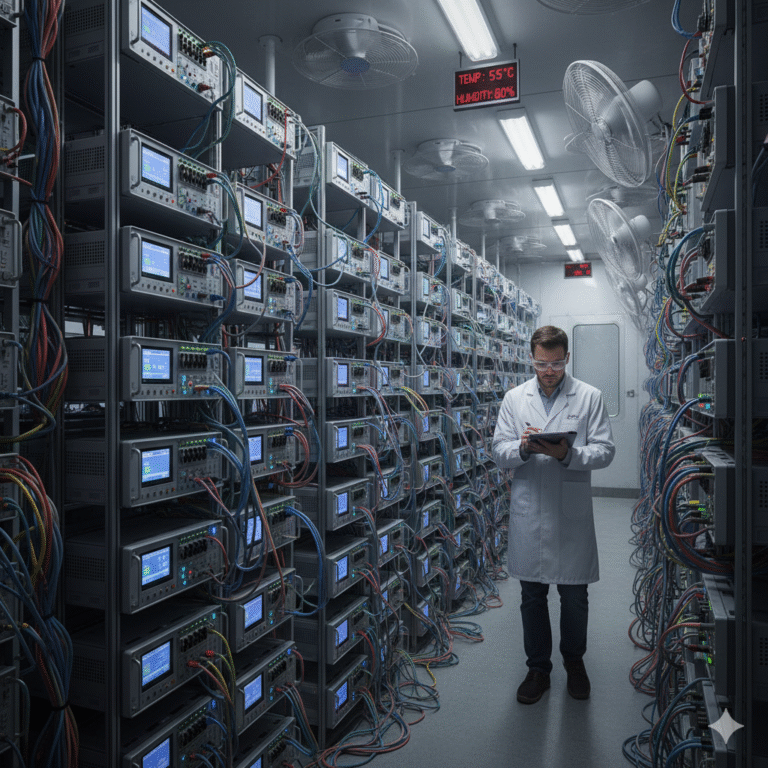

The pre-shipment aging process (also known as “pre-aging” or “seasoning”) refers to the procedure in which manufacturers simulate actual usage environments and conditions before the instruments leave the factory. This involves continuous power-on, loading, or operation for a period of time to stimulate potential failures and stabilize performance parameters.

In simple terms, it is like a strict “pre-shipment training” for the new instruments. Only those that pass this test are deemed “qualified,” ensuring that the products delivered to the customers have stable and reliable performance.

Main Purposes of Pre-Shipment Aging:

Identifying Early Failures:

Aging helps expose early failures caused by component quality issues, soldering defects, material degradation, etc. This process ensures that defective products do not reach the market.Stabilizing Performance Parameters:

It allows the electronic components (such as resistors, capacitors, chips) and mechanical structures of the instrument to stabilize under simulated operating conditions, minimizing parameter drift after shipment.Verifying Product Reliability:

By running the instrument in a controlled environment for an extended period, the reliability of the product is verified, ensuring it meets the design lifespan and performance requirements.

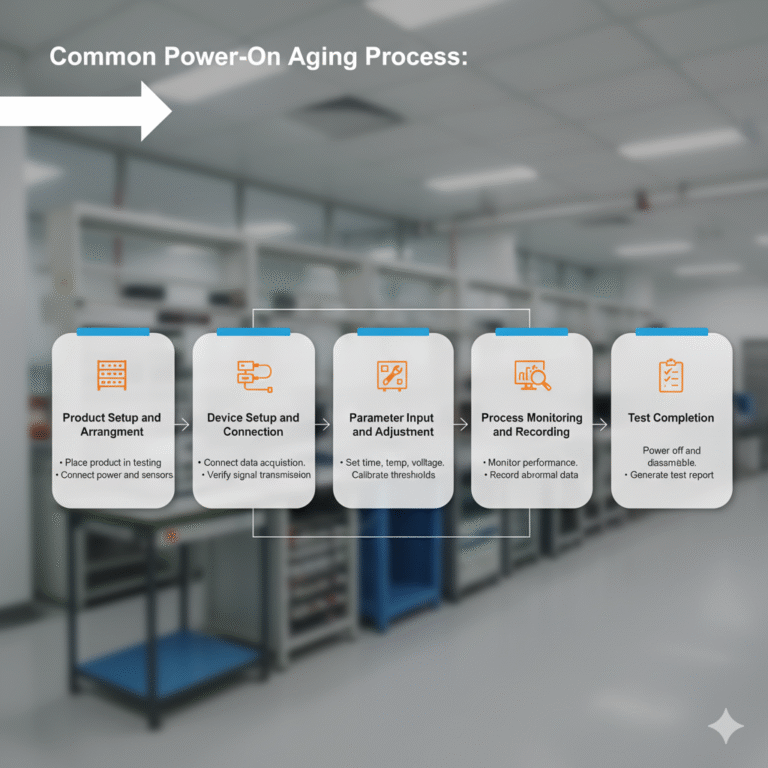

Common Power-On Aging Process:

Product Setup and Arrangement:

Place the product in the testing environment, ensuring that it meets the temperature and humidity requirements. Connect the power supply and test sensors.Device Setup and Connection:

Check the device’s status, connect the data acquisition device, power supply, and monitoring system to ensure proper signal transmission.Parameter Input and Adjustment:

Set the aging time, temperature, voltage, and other parameters, and calibrate the thresholds according to the product specifications.Process Monitoring and Recording:

Once testing begins, continuously monitor performance indicators, record any abnormal data, and periodically save the experimental results.Test Completion:

After reaching the preset time or conditions, power off the device, disassemble the equipment, export the data, and generate the test report.

Conclusion

Aging tests are a critical decision-support tool, providing reliable data to validate product quality. They help identify issues in the design and manufacturing stages, offering directions for improvement. Aging tests are an essential step in ensuring the quality and reliability of instruments, particularly in fields such as industrial control, where precision and stability are crucial.