1. Introduction

In chemical and thermal power industries, instrumentation serves as the “eyes” and “brain” of production. It ensures process safety, reliable monitoring, and stable operation. However, during rainy seasons with frequent thunderstorms, instruments are highly vulnerable to moisture ingress, lightning strikes, and electromagnetic interference.

This document summarizes practical measures for rainproofing and lightning protection, providing engineering guidelines to enhance operational reliability.

2. Rainproofing Measures — Eliminating Risks at the Source

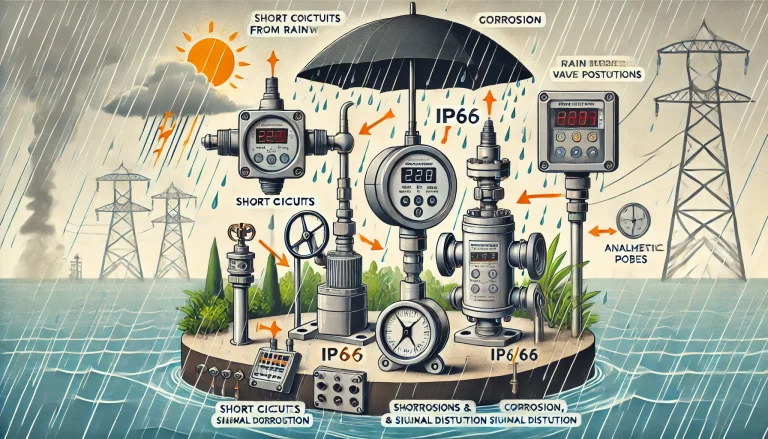

2.1 Instrument Room Sealing and Waterproofing

Ensure airtight sealing of instrument rooms. Doors and windows should be fitted with waterproof strips, and the roof should be equipped with a waterproof layer.

Outdoor instruments should be equipped with waterproof covers or enclosures to prevent rainwater infiltration.

2.2 Drainage System Optimization

Build proper drainage ditches and pipes to ensure quick removal of rainwater.

For low-lying instrument rooms, adopt elevation, waterproof dikes, or pumping systems to prevent backflow.

2.3 Instrument Body Protection

Conduct regular inspections of instrument housings to ensure no cracks or leakage.

Seal all wiring inlets to prevent rainwater intrusion, thereby enhancing long-term reliability.

3. Lightning Protection Measures — Building a Defensive Shield

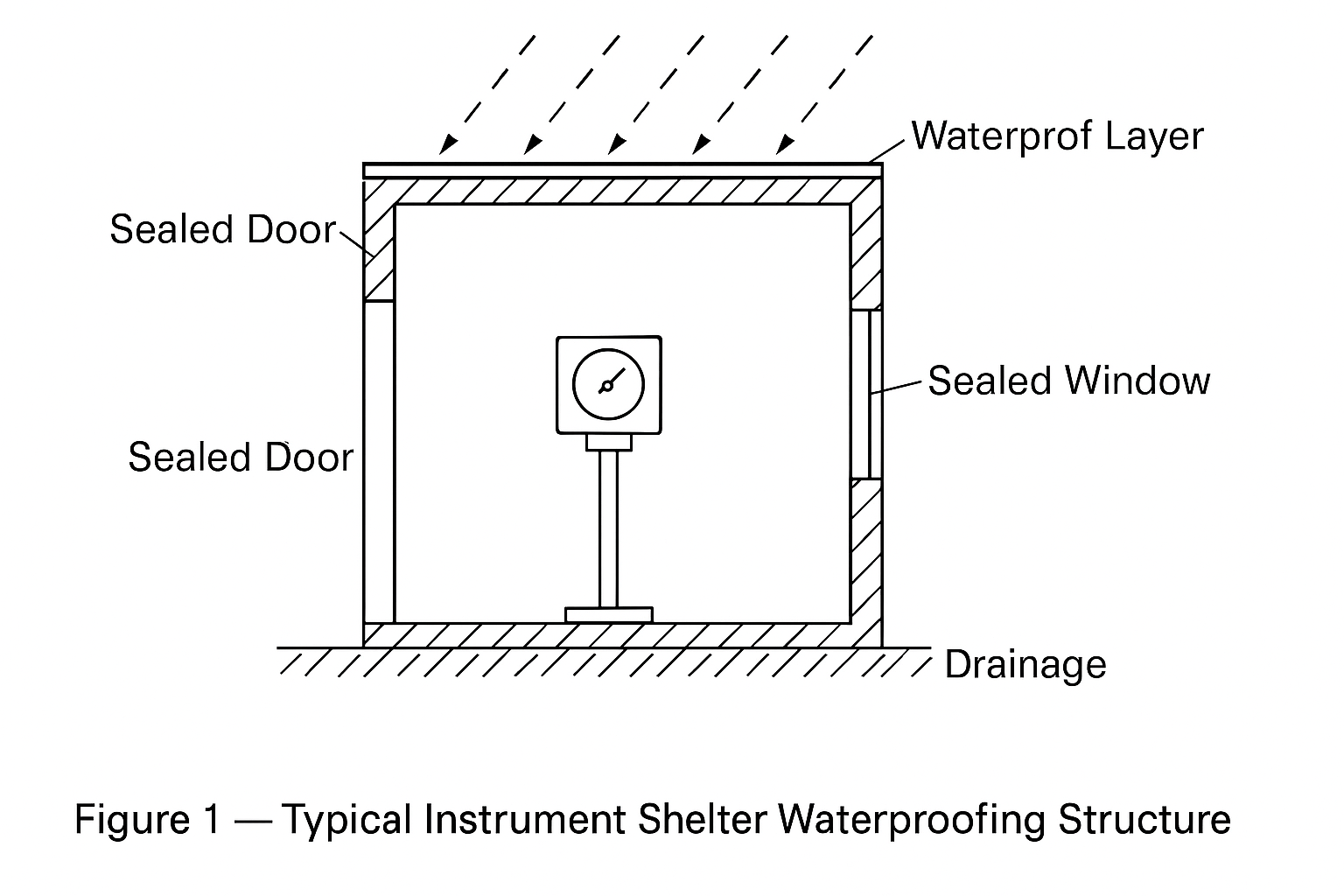

3.1 Grounding System

Ground resistance should be ≤10 Ω, complying with national standards and IEC 62305 requirements.

Critical equipment should use independent grounding systems to avoid backflash from shared grounds.

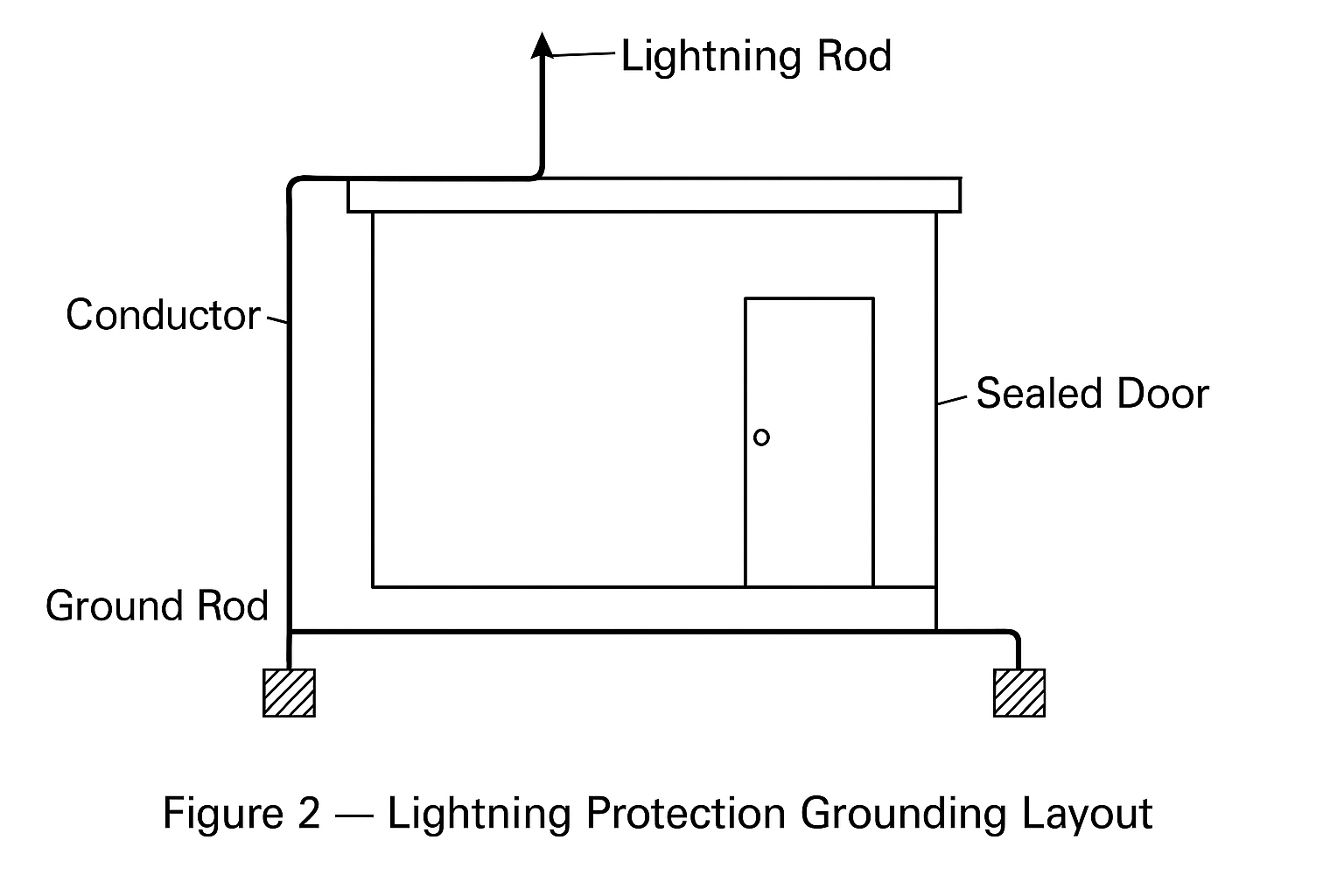

3.2 Surge Protection Devices (SPD)

Install appropriate SPDs at power supply inlets.

Select devices according to voltage level, ensuring efficient absorption of lightning energy.

3.3 Equipotential Bonding

Connect pipelines, frameworks, and equipment into an equipotential network.

This eliminates potential differences and prevents arc discharge or fire accidents.

3.4 Shielding Measures

Use metallic cable trays or conduits to shield cables.

Add shielding enclosures for electronic devices.

Ensure the shielding layer is reliably grounded to reduce Lightning Electromagnetic Pulse (LEMP) interference.

4. Shielding and Grounding Measures — Comparison Table

| Measure Type | Implementation Method | Applicable Scenario | Key Materials | Grounding Requirement | Protective Effect |

|---|---|---|---|---|---|

| Cable Shielding | Metal conduits or trays | Indoor power/control lines | Metallic trays | Shield grounded | Prevents lightning-induced coupling |

| Equipment Shielding | Metal enclosures/shields | Electronic devices | Metallic covers | Equipotential grounding | Blocks electromagnetic interference |

| Comprehensive Shielding | Cable + device shielding | Sensitive areas | Composite shielding materials | System equipotential | Comprehensive risk reduction |

| Grounding Optimization | Connect shielding to ground grid | All scenarios | Ground rods/conductors | ≤10 Ω | Enhanced overall protection |

5. Periodic Inspection and Intelligent O&M

5.1 Grounding System Inspection

Measure ground resistance regularly; correct abnormalities immediately.

5.2 SPD Maintenance

Test operating voltage of SPDs periodically to ensure quick response.

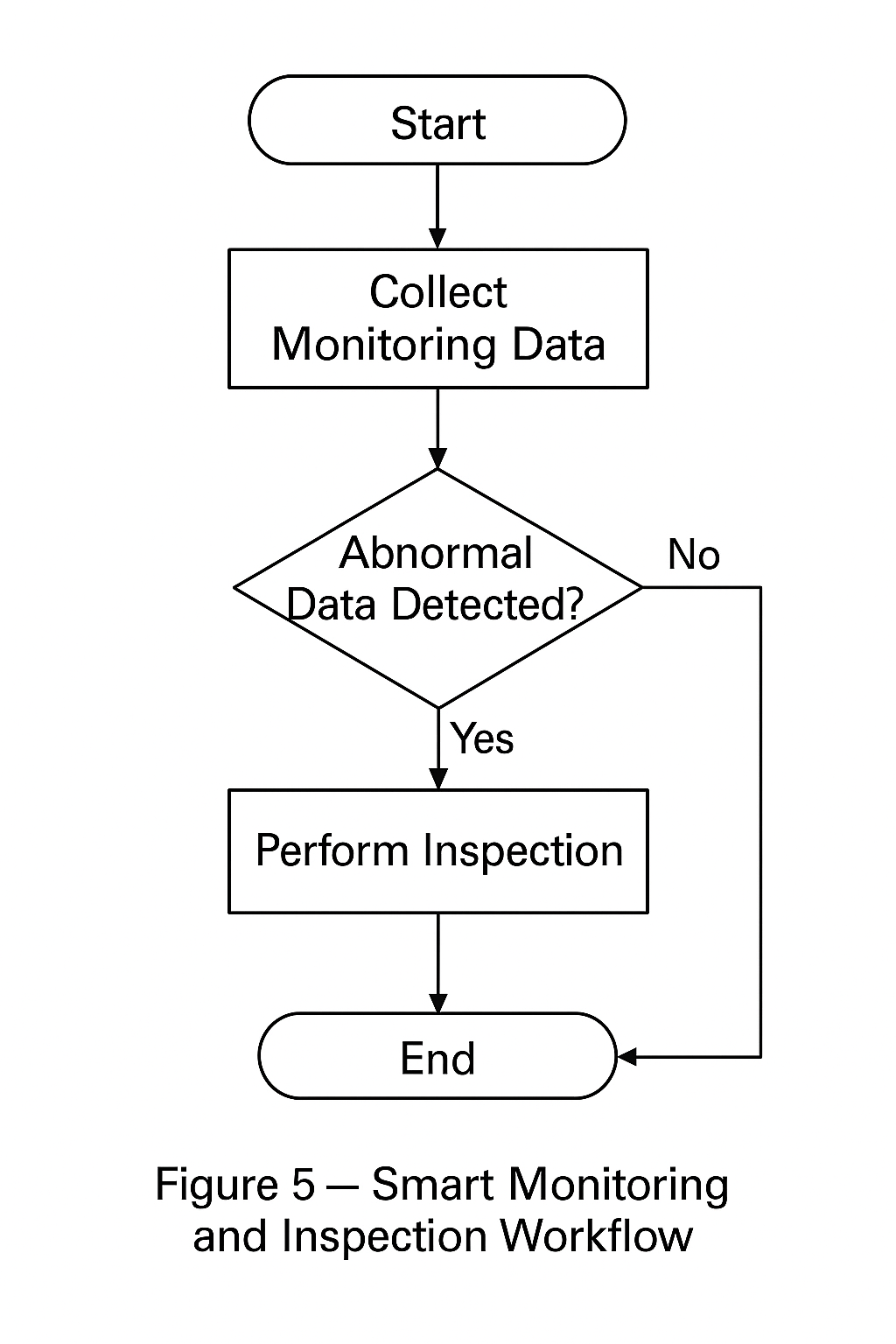

5.3 Intelligent Monitoring

Apply IoT sensors and online monitoring systems to achieve real-time warnings and predictive maintenance.

6. Conclusion

During seasonal “high-risk weather periods,” rainproofing and lightning protection are crucial for ensuring instrument reliability and plant safety. By implementing:

Sealed instrument shelters

Optimized drainage systems

Independent grounding and SPD installations

Equipotential bonding and shielding techniques

Periodic inspection and intelligent monitoring

Enterprises can establish a multi-layered defense system, reduce downtime risks, and support sustainable, safe, and efficient production operations.