Pressure sensors are critical components in industrial automation and process control. For many purchasing engineers, the challenge lies in selecting the right type of pressure sensor for a given project or equipment. This guide outlines the four key parameters that should always be considered: measuring range, accuracy, medium compatibility, and pressure reference type.

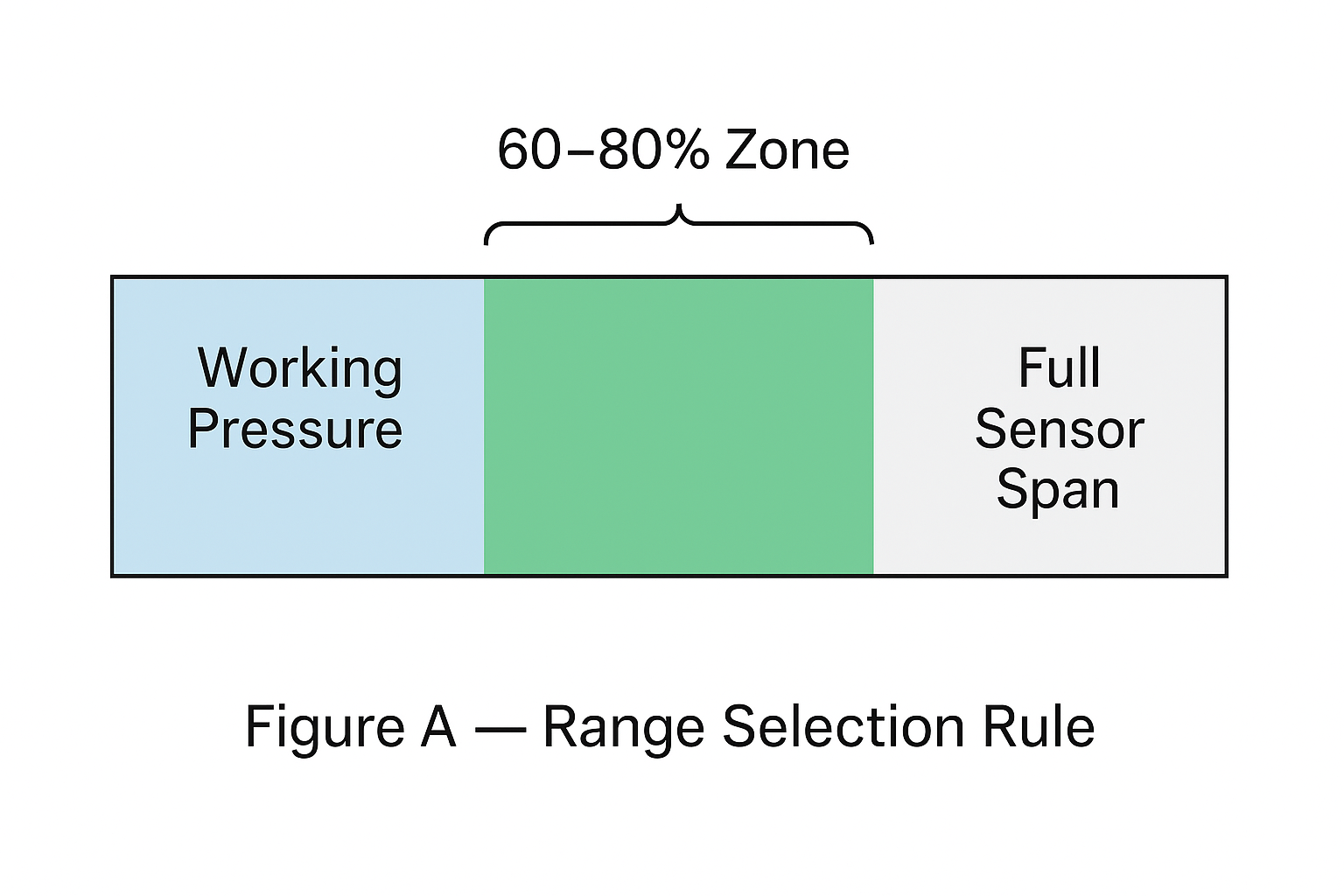

1. Measuring Range Selection

Rule of thumb: Select a range where the normal working pressure falls within 60–80% of the sensor’s full-scale range.

Overload protection: Ensure that the maximum possible abnormal pressure does not exceed the sensor’s overload rating.

Example:

System operating pressure: 10 MPa

Recommended sensor range: 16 MPa (normal operation ≈ 62% of FS)

2. Accuracy Requirements

Accuracy directly impacts process stability and measurement reliability.

Selection principle: Choose the accuracy class based on system requirements and budget. Higher accuracy = higher cost.

Error factors: Besides rated accuracy, consider:

Zero drift over time

Temperature coefficient of zero and span

Long-term stability

| Application Scenario | Recommended Accuracy Class |

|---|---|

| General industrial processes | 0.5% FS – 1.0% FS |

| Energy & chemical plants | 0.25% FS |

| Laboratory or calibration | 0.1% FS or better |

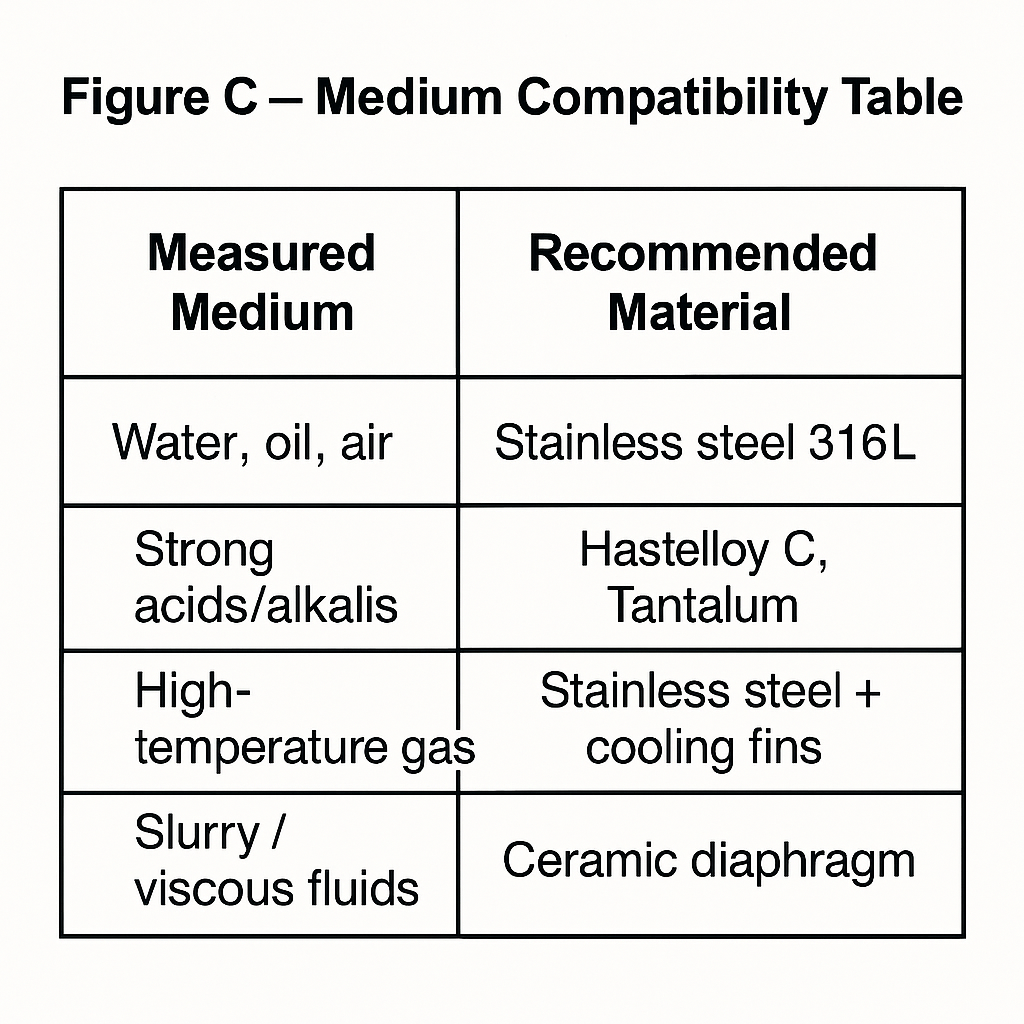

3. Medium Compatibility

The wetted parts of a pressure sensor (diaphragm, housing, process connection) must be compatible with the measured medium. Selecting the wrong material can cause corrosion, leaks, or sensor failure.

| Measured Medium | Recommended Material |

|---|---|

| Water, oil, air | Stainless steel 316L |

| Strong acids/alkalis | Hastelloy C, Tantalum |

| High-temperature gas | Stainless steel + cooling fins |

| Slurry / viscous fluids | Ceramic diaphragm |

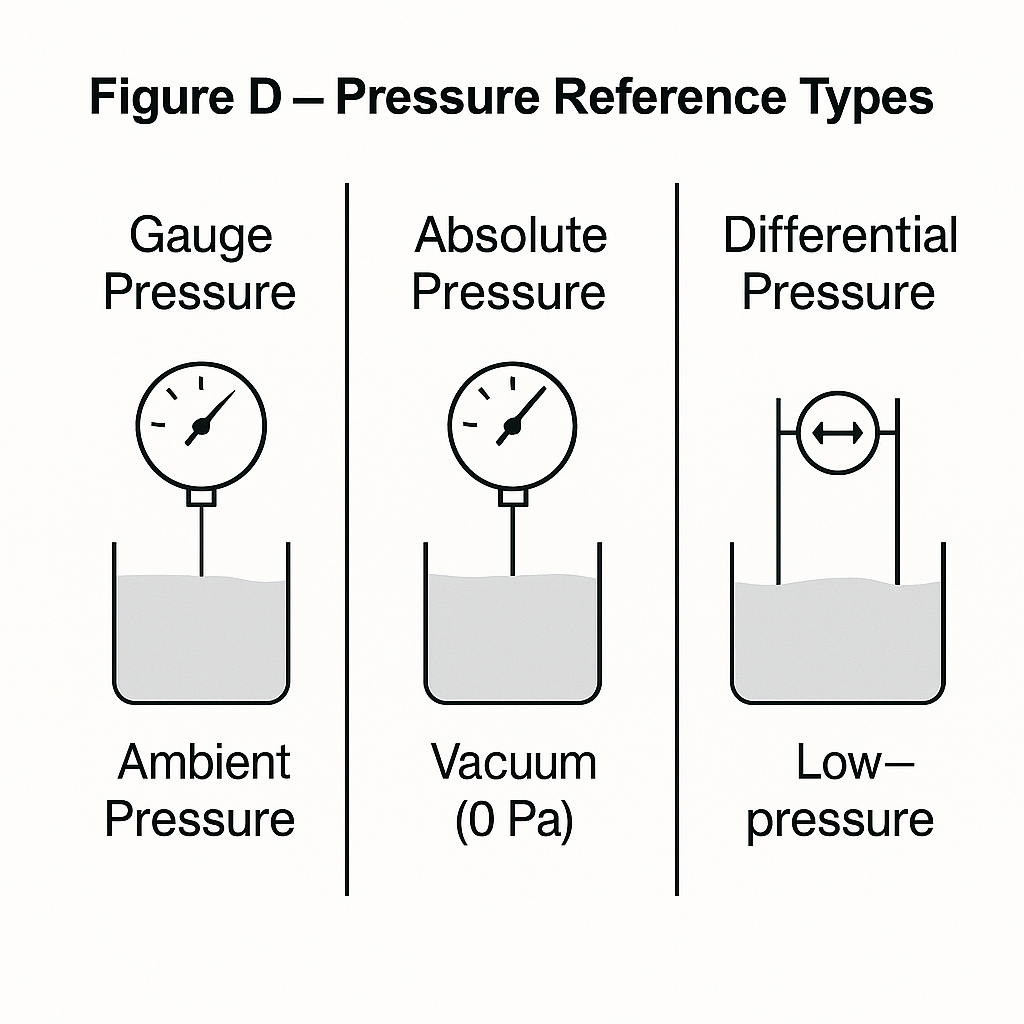

4. Pressure Reference Type

Pressure sensors are available in different reference types. Selection depends on the nature of the pressure being measured.

| Type | Description | Typical Applications |

|---|---|---|

| Gauge Pressure | Relative to ambient atmosphere | Pumps, pipelines |

| Absolute Pressure | Relative to vacuum (0 Pa reference) | Scientific research, sealed systems |

| Differential Pressure | Measures the difference between two points | Filter monitoring, tank level measurement |

| Negative Pressure | Measures vacuum below atmospheric pressure | Vacuum packaging, leak detection |

Liquid level note:

If the liquid tank is open to atmosphere → gauge pressure sensor is sufficient.

If the tank is sealed or pressurized → differential pressure sensor is required.

✅ Conclusion

When selecting a pressure sensor, purchasing engineers should evaluate:

Measuring range to cover normal operation without exceeding overload.

Accuracy to balance cost and performance.

Medium compatibility to ensure long service life.

Pressure reference type to match the actual measurement condition.

By combining these four considerations, you can achieve a safe, cost-effective, and reliable sensing solution for your project.