The performance of general-purpose electromagnetic flowmeters on the market is quite different. Some have high accuracy and many functions; some have low accuracy and simple functions. The accuracy grades of high-precision instruments are 0.5 and 1, the basic error is usually ±(0.5-1)%R, and the low-precision instruments are ±(1.5-2.5)%FS.

Some models of instruments claim that the accuracy level is 0.2 or 0.3, and its basic error is only: (0.2-0.3)%R, but maintaining this accuracy often requires strict installation requirements and narrow reference conditions. For example, the ambient temperature should be in the range of 20~23℃, and the length of the front and rear straight pipe sections must be greater than 10D, 5D (usually 5D, 2D).

It is even proposed that the flow sensor should be integrated with the front and rear straight pipe sections, and then the flow standard device should be installed. Real-flow calibration to reduce the impact of improper clamping (such as the misalignment of the flow sensor and the pipe axis, the sealing gasket protruding into the pipe, etc.).

Therefore, when comparing and choosing various types of instruments, you should not simply look at the high indicators. You should read the manufacturer’s samples or instructions for comprehensive analysis.

The basic error of the full-flow non-full-tube electromagnetic flowmeter is ±(1.5~2)%FS.

The basic error of the plug-in instrument itself (that is, the flow rate detection head) is generally ±2%R-±4%FS. Considering that the point velocity represents the average velocity of the surface, and the velocity distribution coefficient will vary from 2% to 5% with the flow rate within the measurement range, the measurement error of the flow area and the distortion of the velocity distribution caused by the interference of the spoiler, the overall The measurement accuracy is even lower.

If the plug-in electromagnetic flowmeter is applied to the large diameter and long water pipeline, because there is generally enough front straight pipe length and good speed distribution, for example, the electromagnetic flow rate detection head is individually calibrated in the “verification water tank”, and the flow range is And there is little change, and there are no better conditions such as the speed distribution coefficient change, the basic error can be close to or slightly greater than +2%R.

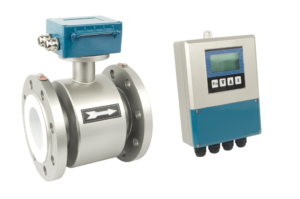

Electromagnetic flowmeters with simple functions can only measure one-way flow, and only output analog signals to drive the back-level instrument; instruments with more functions can measure two-way flow, range switching, upper and lower limit alarms, flow display, total accumulation, and automatic verification. And fault diagnosis, communication with the host computer and remote control configuration, etc.

The serial digital communication function of some models can also choose various communication interfaces and special-purpose chips (ASIC) to connect to the HART protocol system, PROFIBUS, FF Fieldbus, etc.